Auto Duct Production Line 4

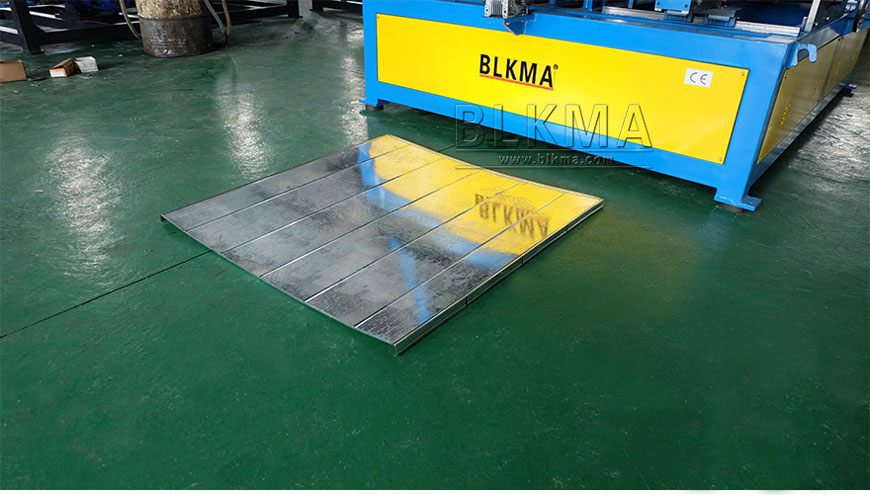

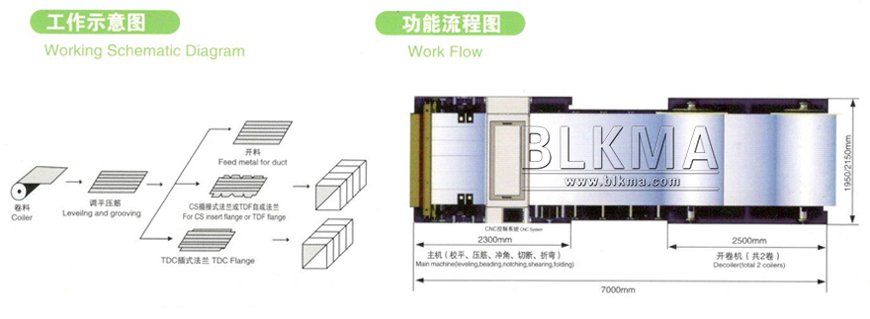

It's mainly for uncoiling, leveling, beading, punching, locking, bilaterally angle steel or TDF flange forming. Because of its small space requirement and easy to install and operate, people also call it "small line 5".

Auto Duct Production Line 4 Performance Features:

The function of auto duct production line 4 mainly includes unwind, leveling, beading, notching, locking and flange forming. Theduct manufacturing equipmentof auto duct line 4 is used to level, bead, notch, and shear. All the rolling reels are made of bearing steel so that the lifetime will be prolonged. The injection holes are used on both sides of the drive shaft to enhance the bearing life. There is the material-saving mode. The machine can withdraw sheet metal automatically. Besides, the auto duct line 4 machine has the production record function. The operator can check production order. The imported configuration includes Germany Festo cylinder, Bejing Huade and Taiwan hydraulic system, Taiwan Hiwin linear guideways and Schneider electric system. Cnc system is Japan Mitsubishi. Meanwhile, the basic configuration includes two electric material racks (4 material trays, 5-7T each roll), one rack, one main machine (line 2 host), one mechanical arm for clutching, locating and transferring, one lock forming machine, one duplex TDF flange forming machine, one duplex angle steel flange forming machine and a set of computer controlling system. The operator can use the auto duct line 4 machine with other square duct machines, for example, hydraulic/pneumatic/manual folding machine, hydraulic/pneumatic/electric lock seam closing machine, corner punching machine, corner assembly machine and so on together to complete the whole duct. The line 4 machine can make max sheet thickness 1.2 mm. For sheet width, there are two models that can be chosen, max width 1300 mm or max width 1500 mm. Our company can provide customers different choice according to different requirements. You can contact us at any time you want via , mob, WhatsApp, Skype, facebook, youtube and question about HVAC duct manufacturing machines. Besides, we can provide engineer overseas service if customers need.

Auto Duct Production Line 4 Main import Configuration:

Cylinder imported from Germany Festo Mitsubishi CNC control system Japan Omron encoder Taiwan Hiwin linear guideways Schneider electrical system

Auto Duct Production Line 4 Basic Configuration:

Two electric coil cradles, 4 material trays (5-7t each roll) One rack One host (line 3 host) One mechanical arm clutching, locating and transferring platform One displacement type locking machine One duplex TDF flange forming machine One duplex angle steel flange forming machine One set of computer controlling system

在线联系供应商

Other supplier products

| Auto Duct Production Line 3 | Duct production line 3 can drive blanking for duct. Meantime, it’s very suitable for diversified production like TDF/angle steel/inserted fla... | |

| CNC Plasma Cutting Machine | BLKMAis a company from China. Founded in 1994, it is located in Ma'anshan, Anhui Province, China. It is only 26 kilometers away from Nanjing Lukou ... | |

| Round Duct Lock Seam Machine | Round Duct Lock Seam Machine Performance Features: Model Thickness of plate(mm) Machining length(mm) Weight(kg) Power(kw) Dimensions(mm) L*W*H YJB-... | |

| Pneumatic TDF Folding Machine | Pneumatic TDF folding machine is very important for duct production, The weight and the volume of the device itself is not large, and this machine ... | |

| Hydraulic Folding Machine | In the heavy industrial machineryindustry in China, BLKMAis the most authoritative modern enterprise, which participated in the national Chinese pi... |

Same products

| Full automatic double end terminal crimping machine 2Pin flat wire | 卖方: 816004 | product link: Features Full automatic terminalcrimping machine, using high-tech frequency con... | |

| 桥式双端剪力梁式称重秤QSF50~75klb适用于电子汽车衡 | 卖方: 宜兴市三维电气制造有限公司 | 桥式双剪力梁,独特的浮支承结构 自复位,具有良好的侧力和抗冲击性能 防潮密封,适用于恶劣环境 安装简单,使用方便,互换性好 适用于电子汽车衡、铁路衡、料斗秤及各种特殊秤。 | |

| 用于筒仓称重称重传感器1t-20t | 卖方: 宜兴市三维电气制造有限公司 | 与托利多FW称重模块完全兼容;额定载荷: 500kg ~ 20000kg;结构独特,可方便地安装在各种槽罐上;三种顶板结构(固定式、半浮动式、浮动式)可以消除槽罐因热涨冷缩带来的称量误差;支撑螺... | |

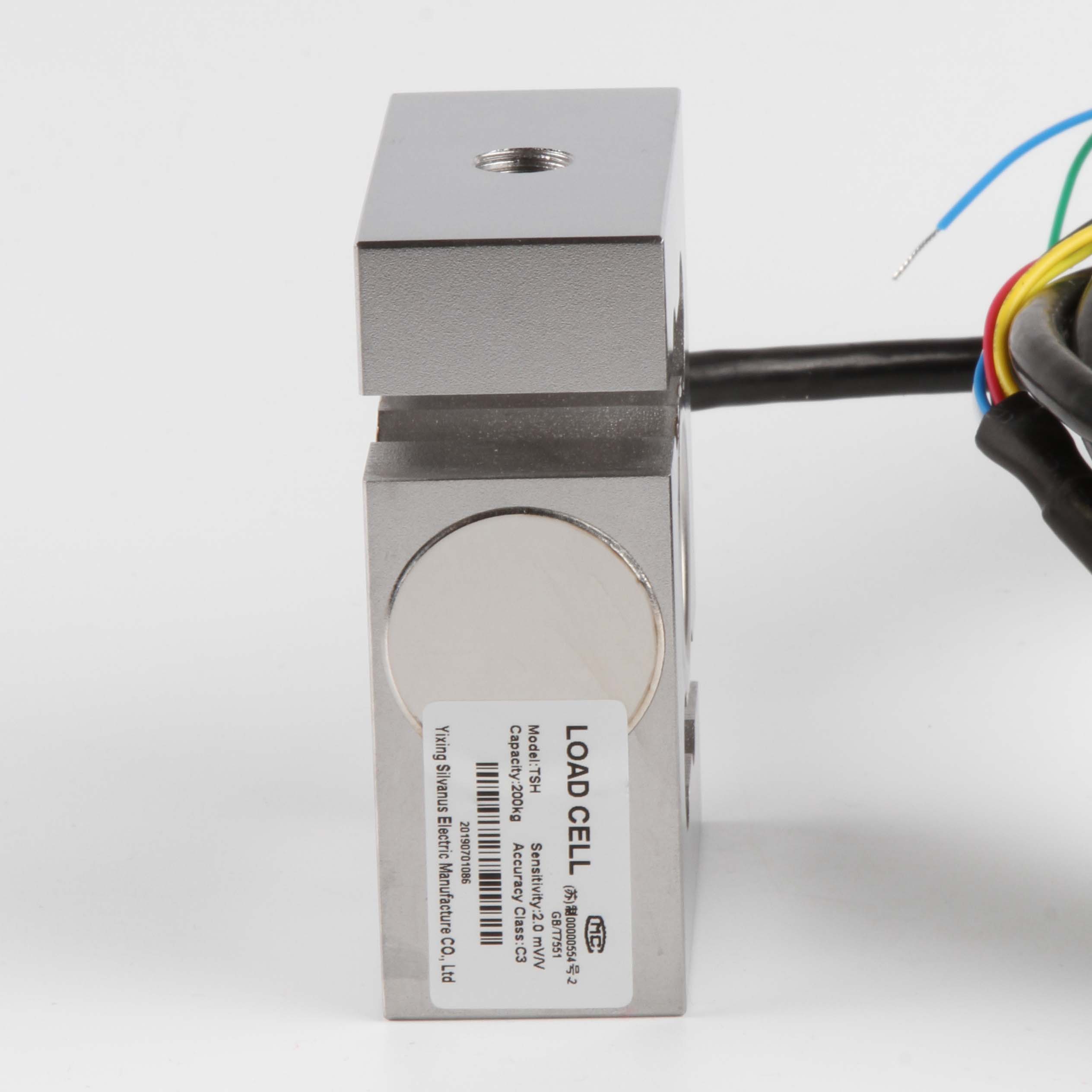

| S 类型 负载 细胞 , 张力 和 压缩 高精度合金钢200 -5000kg S型称重传感器,适用于机电秤、吊车秤、料斗秤 | 卖方: 宜兴市三维电气制造有限公司 | TSH型钢制“S”型称重传感器,承受拉、压外力均可,输出对称性好,结构紧凑、安装方便,规格齐全。可用于制造机电结合秤、吊钩秤、料斗秤及各种专用秤、工艺秤等。 | |

| 600*600 ceiling panel machine | 卖方: Foshan lesheng metal machinery co.,ltd |