GlobeCore

Contact information

GlobeCore was established as a subsidiary trade company of Ukrbudmash, Ltd. and now is one of the leading manufacturers in the field of development and implementation of industrial equipment for reclamation, purification, drying and degassing of transformer, turbine, industrial and other oils, reclamation of all kinds of mineral oils with restoration of color and operational specifications, as well as manufacturing of other high voltage service equipment . Oil reclamation involves new technologies in energy sector and industry in general. Company is located in Poltava, Ukraine; it has its subsidiaries and dealer network allover the world. The equipment is in compliance with all relevant international standards. All products certified accordingly. Quality control complies with ISO 9001:2001. Certificate No UA.2.039.02021-06. Company obtains numerous operating facilities and keeps over 200 highly qualified workers, engineers and employees on its payroll. The equipment produced by the company boasts up-to-date design and high performance due to recent developments of the experienced engineering staff. Our primary business areas are: - Design and production of equipment for transformer oil purification, dehydration, degassing and regeneration on a worldwide basis. - Design and production of equipment for industrial oil filtration (diesel oil, turbine oil, lubrication oil). - Servicing of existing equipment and sale of spare parts worldwide. - Development and efficiency improvement of purification and regeneration equipment for the energy industry and related industries. - Design and production of road construction equipment (bitumen emulsion plants, polymer modified bitumen plants, bitumen storage plants, bitumen filtration units, colloid mills etc.). - Design and production of liquid/fuel/boidiesel blending machines. - Design, construction and commissioning of Bio Diesel Plants. Equipment list is presented in the product section of this website, where you can also find detailed descriptions of products, photos and technical data. For full view, select corresponding menu item.

Products:

| GlobeCore UVB-2 modified bitumen batch unit 4-7 m3 per hour | UVB-2 modification unit is designed for production of modified bitumen, including polymer bitumen binding for preparation of top coat asphast-concr... | |

| GlobeCore UMBP-22P capacity 22 m3 per hour | UMBP-22P bitumen modification unit is designed for production of modified bitumen, including polymer bitumen binding for preparation of top coat as... | |

| GlobeCore UVB -1 productivity of 1 m3 per hour | UVB-1 bitumen unit is designed for production both anionic and cationic bitumen emulsions, which are used in road construction as follows: base coa... | |

| GlobeCore UVB -1 productivity of 2 m3 per hour | UVB-1 bitumen unit is designed for production both anionic and cationic bitumen emulsions, which are used in road construction as follows: - base ... | |

| GlobeCore Transformer Oil Regeneration Plant | The Plant’s design includes Fuller’s Earth reactivation in situ for continuous reuse of Fuller’s Earth. Fuller’s Earth regeneration facility will a... | |

| GlobeCore INEY transformer oil refrigeration unit | GlobeCore is proud to offer INEY vacuum and refrigeration drying cold trap for processing of solid insulation in transformers in the range of 110 &... | |

| GlobeCore Vacuum Systems BV series | Vacuum Systems BV series Application Vacuum Pump Units BV series are designed for puling vacuum on the transformer tank. Vacuum fill ensures that ... | |

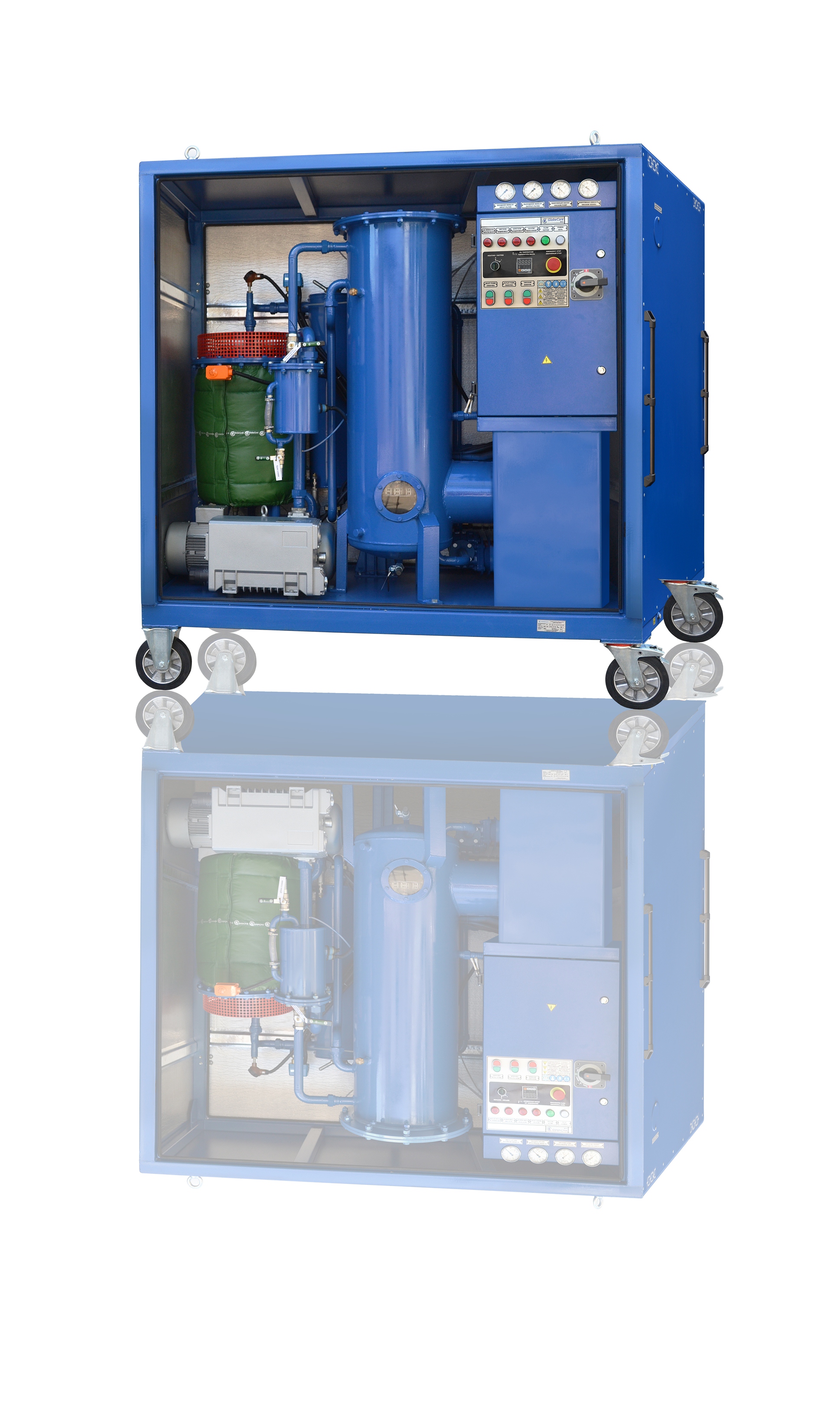

| Globe Core Transformer Oil Purification Plant CMM (UVM) 10 with High Vacuum | Removes Water from 100 ppm down to 10 ppm and from 50 ppm to 5 ppm in a single pass (ASTM method D-1533) Reduces Gas content from fully saturated w... | |

| Globe Core Transformer Oil Purification Plant CMM (UVM) 4 with High Vacuum | Removes Water from 100 ppm down to 10 ppm and from 50 ppm to 5 ppm in a single pass (ASTM method D-1533) Reduces Gas content from fully saturated w... | |

| Globe Core Mobile Transformer Oil Purification Plant CMM 4 | - Removes Water from 100 ppm down to 10 ppm and from 50 ppm to 5 ppm in a single pass (ASTM method D-1533) - Reduces Gas content from fully satura... | |

| Globe Core Transformer Oil Purification Plant CMM 0.6 | Removes Water from 100 ppm down to 10 ppm in a single pass and down to 5 ppm after 3 passes (ASTM method D-1533); - Removes Particulate Matter to ... | |

| Globe Core Turbine Oil Purification Plant CMM 4T | GlobeCore CMM 4T – Oil Purifier designed for removal of solid particles and free and dissolved water from industrial oils. Use of Racshig Rings in ... |