GlobeCore INEY transformer oil refrigeration unit

GlobeCore is proud to offer INEY vacuum and refrigeration drying cold trap for processing of solid insulation in transformers in the range of 110 – 1150 kV. The unit is designed to be used for transformer installation, servicing and repairs.

Three types of units are manufactured, which are different in terms of components, operation modes and specificaions. All types are equally good are their jobs.

Type one: single with double stage refrigerator capable of temperature to -70oC.

Type two: a composite unit with a vacuum pump: one module is a double stage refrigerator as described above, the other module is equipped with a backing pump and a liquid cooling and heating system.

Type three: a composite unit, one module is a double stage refrigerator, the other module is equipped with three backing pumps and a vacuum pump.

Select the best option for the requirement of your facility.

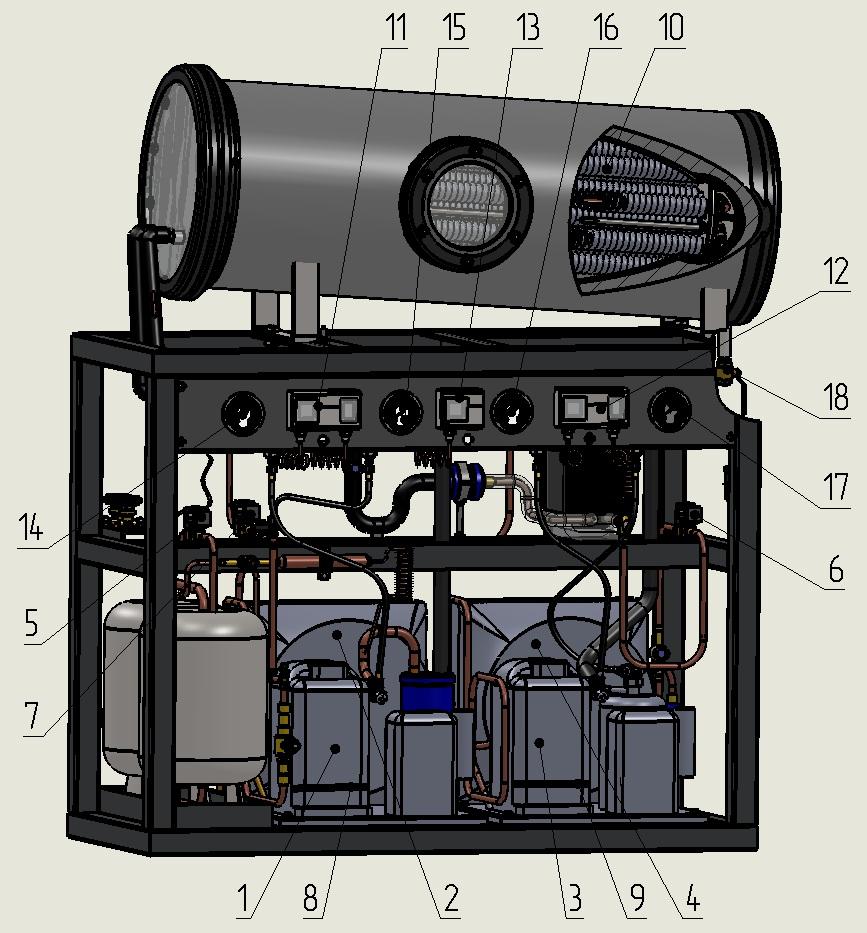

Refrigeration section

1 – compressor 1; 2 – fan 1; 3 – compressor 2; 4 – fan 2; 5 – solenoid valve; 6 – solenoid valve 1; 7 – solenoid valve2; 8 – compressor crankcase heating 1; 9 – compressor crankcase heating 2; 10 – evaporator; 11 – double channel pressure relay 1; 12 – double channel pressure relay 2; 13 – single channel pressure relay ; 14 – pressure and vacuum gague “Input pressure” 1; 15 – pressure and vacuum gague “Output pressure” 1; 16 – pressure and vacuum gague “Input pressure” 2; 17 – pressure and vacuum gague “Output pressure” 2; 18 – condensate drain valve.

The unit operates in the following modes:

«COLD ACCUMULATION»

The surface of the evaporator decreases gradually to -700С.

«FREEZING»

After reaching the pre-defined temperautre of-700С, the system automatically switches to cyclic operation, where some components are stopped and started as required.

«EVAPORATOR DEFROST»

As moisture accumulates in the evaporator, it must be removed by defrosting. The defrosting process takes approximately 30 minutes.

When the evaporator reduces the temperature in the cold trap to -70oC, the difference of vapor pressure in the trap and over the solid insulation of the transformer (e.g. saturated water vapor pressure at +20oC is 2337 Pa, and only 18 Pa at -40oC), drives the water vapor from the transofrmer tank into the cold trap, where it freezes in the evaporator. The duration of drying depens on how much moisture is present in the transformer, inside and outside temperatures, as well as residual pressure in the transformer tank. The unit can operate continuously for 20 days.

A sight glass in the insulated cold trap allows to observe the process visually. A condensate drain valve in the bottom of the trap facilitates removal of condensation after defrosting. The unit is capable of trapping 7.5 kg of moisture in 24 hours approximately.

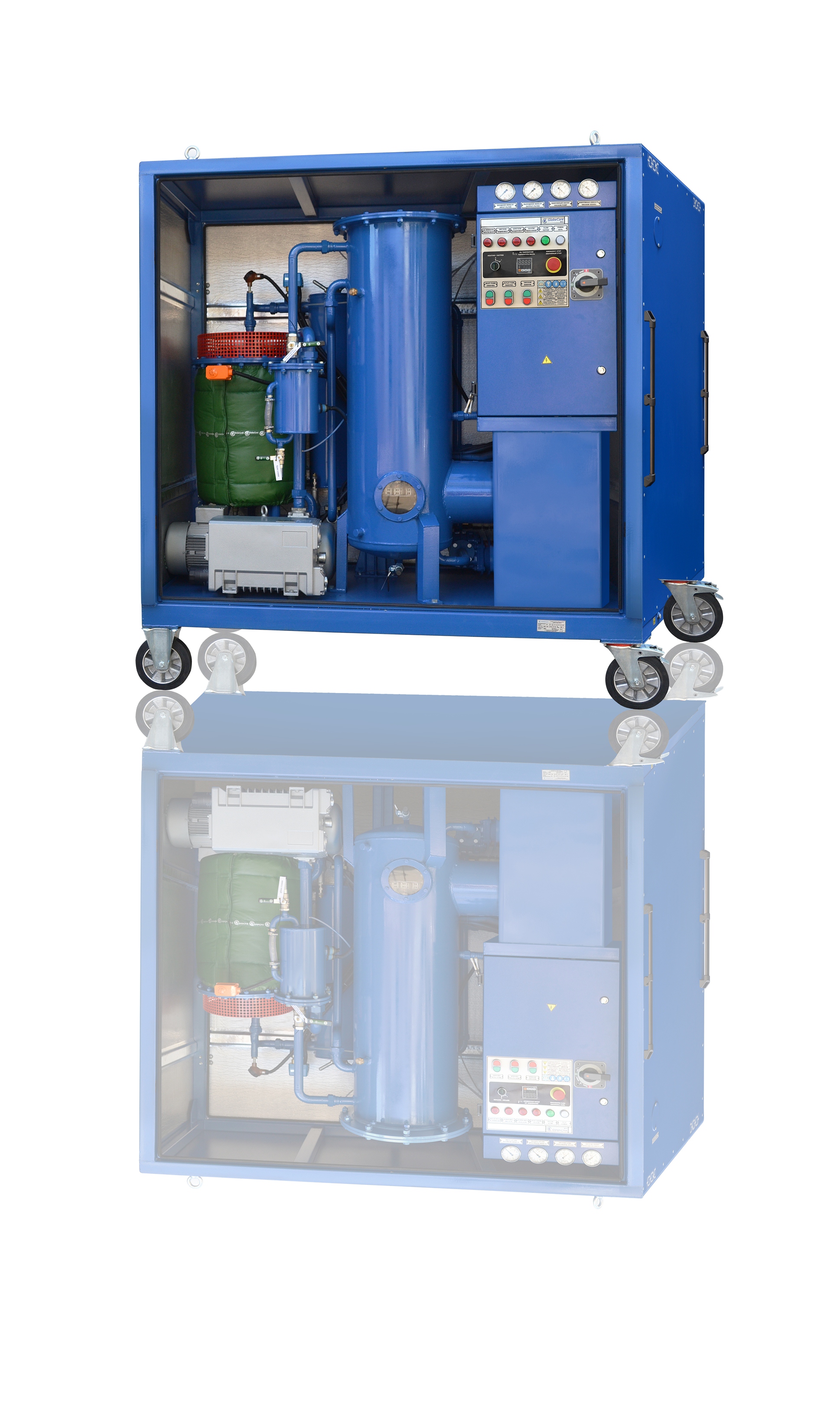

(INEY system in late stages of assembly)

This product is accordingly certified with documents regarding the system’s quality and standards, just as any other product by GlobeCore.

The factory is located in Poltava, Ukraine, ul. Sadovskogo, 8.

The manufacturing time of the unit is 45 to 60 business days depending on selected options.

GlobeCore provides effective solutions to the equipment needs of your facility. Contact our sales manager for assitance in selecting the necessary options, sale terms and conditions, as well as commissioning and contract conclusion. After that the ordered unit is manufactured. This stage is the longest, and in this time we welcome you to visit our facility and witness the process of manufacturing of your product, as well as other products. When production is complete, the product is tested for acceptance and is shipped to the client.

We are always open to cooperation.

Other supplier products

All supplier products

Same products