Huzhou Yingnuowei Machinery Co.,Ltd

Contact information

Innova machinery is a one stop shop to get all of your vibrator deburring and finishing compound and chemicals together with right processing vibratory deburring or polishing abrasive media. Whether it can be ceramic media, plastic media, steel media, and natural finishing media like corn cob or walnut shell.

Customizing your specific requirement for surface finishing, we will design your requirement for loading hoppers, separation device and also machinery after finishing including cleaning and drying. We offer a complete assortment of equipmentto assist with the loading, unloading and deliveringheavy industrial components from vibratory tumbling, deburring equipmenttransferable without any need for interaction, over onto the nextstage or connect fluently with your existing production facility, anywhere, to your operators unloadingtable, we are here to help you from the very beginning to the very end.

Products:

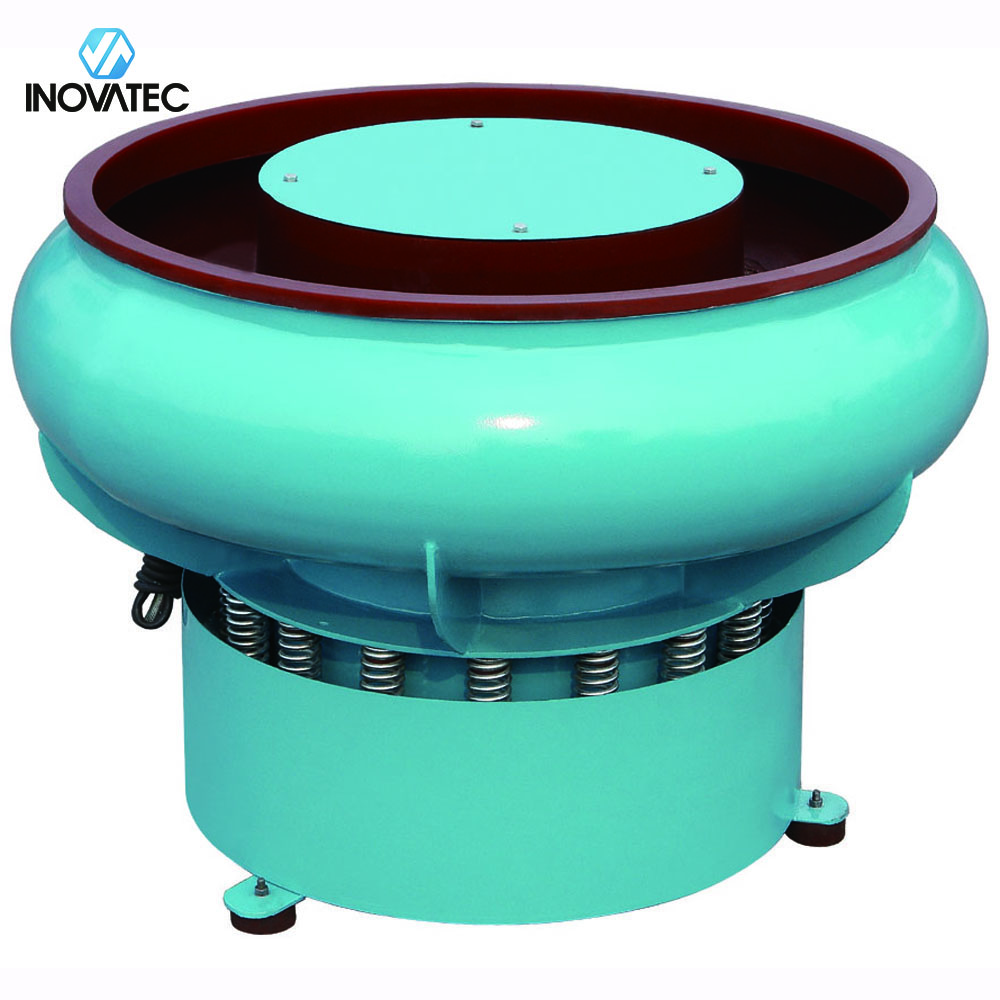

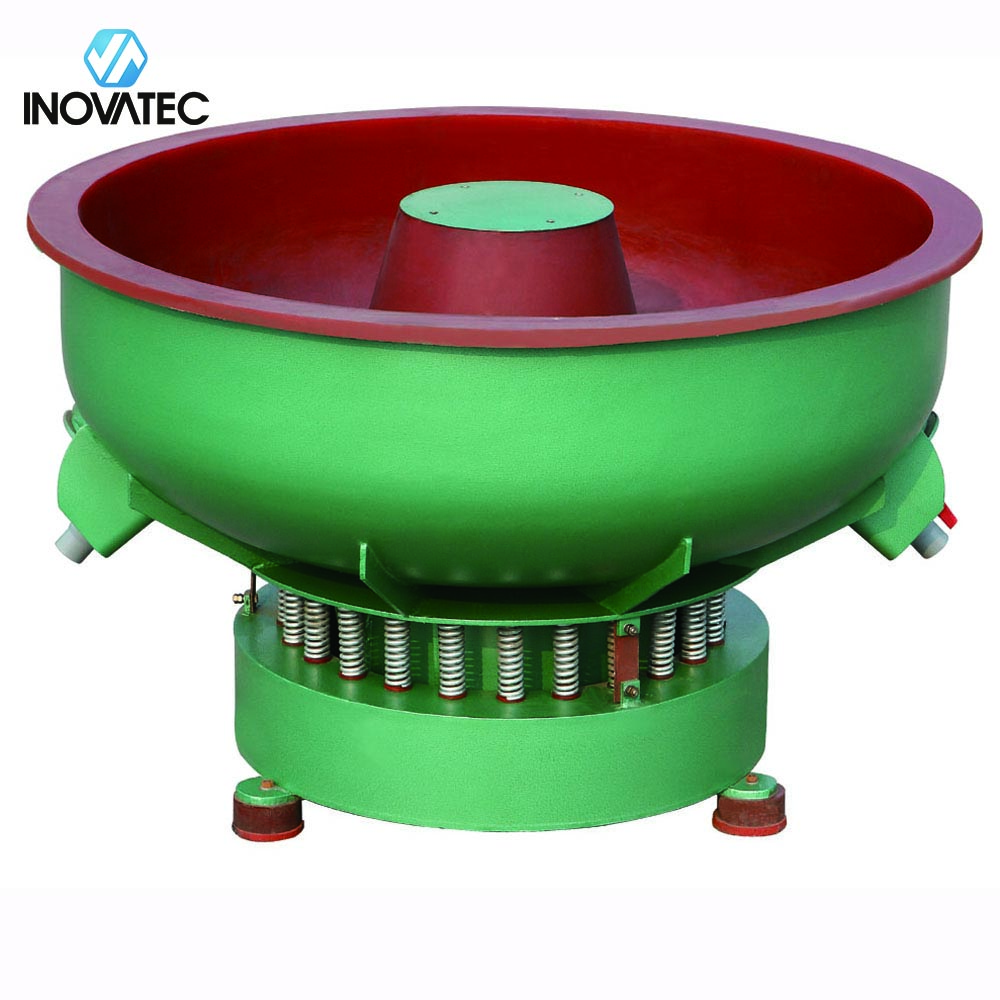

| Vibratory finishing machine for Roto finish | Standard Features: Easy to change the separation deck Heavy-duty long service vibration motor Optional VFD (Variable Frequency Drive to control mo... | |

| Vibratory polishing machine for mass finishing Rotofinish | Standard Features: Effective motor position for Excellent Vibration. High tensile bolts and nuts for long service life of motor and machinery. Ef... | |

| Magnetic separator | Technical details: The angled magnetic head and the permanent magnetic field with pulsating poles facilicates the release of trapped media in the ... | |

| Vibratory Separator – Vibratory Sieve | Features: Noise free operation Easy installation and maintaince Optimum performance Specification: Higher Capacity Per Unit Of Screening Area Long ... | |

| Centrifugal disc finisher – Jewelry Polishing Machine | Introduction The patented adjustable gap system of the VA series enables a precision of 0.05mm. This unique setting of the gap between the disc and... | |

| Zero Gap Centrifugal Disc Finishing Machine Otec Design CF series | Feature: Highly user friendly The rotational speed, machine running time (forward/backward respectively), compound dosing as well as other process... | |

| Zirconia ceramic ball – zirconia polishing ball | Introduction: Innova ZR-320 Ceramic Beads provides a higher wear resistance than porcelian media RP, which can be used as a cost-effective ultra-fi... | |

| Ceramic tumbling media – RS ceramic media tumbler media | RS ceramic grinding media is produced by mixing porcelain, kaolin,clay, river clay together with brown alumina oxide abrasives. The wet material i... | |

| Plastic grinding media – RKX plastic grinding chips | RKX plastic media is preformed plastics, the other workhorse media, are also available in a variety of grades or bodies, with some manufacturers ha... | |

| Stainless tumbling media | Steel Tumbling Media allows for faster finishing times, eliminates the need for expensive, consumable compound solutions and rust inhibitors, and r... | |

| Ceramic Polishing media – RP media | RP Ceramic Polishing Media RP media is fine porcelain media with specific gravity 2.91, while have no included abrasive inside the recipe, can dev... | |

| walnut tumbling media – crushed walnut shell tumbling media | Walnut shells are used for stamped, formed, or chemically etched thin sheets of brass or beryllium copper.Small screw machine parts and jewelry are... | |

| Corn cob tumbling media – corn cob for cleaning and drying | Crushed and graded corncobs are usually used to dry parts as they absorb the water from wet parts.This eliminates watermarks or stains that are obj... | |

| Ceramic deburring media – RMB/D1 polishing abrasive | RMB/D1 ceramic grinding media is produced by mixing porcelain, kaolin,clay, river clay together with brown alumina oxide abrasives. The wet materi... | |

| Plastic deburring media – RKP Plastic tumbling media | RKP plastic media is preformed plastics, the other workhorse media, are also available in a variety of grades or bodies, with some manufacturers ha... | |

| Centrifugal barrel finishing machine – Tumbling Barrel – barrel process | Feature User friendly Easy maintenance High-precision finishing operation Short finishing time Ultra-high performance machine for finishing ap... | |

| Centrifugal barrel tumbling – Harperizer – barrel deburring | Centrifugal Barrel Finishing Machines are high gravity force machines which specifically developed for smaller and precision components; also it is... | |

| Crankshaft Polishing machine | Applications: Applied to all kinds of shafts,poles,covers parts surface treatment.Polishing,grinding,rounding and deburring without change parts o... | |

| Longitudinal vibratory finishing machine – Continuous | Introduction Recently with increasing cost of manual polishing process and high requirement of automation, continuous linear vibratory finishing... | |

| Grinding and heating production line | Well-designed equipment with easy separation capabilities allows simple, fully automatic or semi-automatic system to be developped with ease. This ... | |

| Automatic Vibratory finishing machine production line | Rotomatic is suited for continuous running deburring, grinding, cleaning, deflashing and other surface treatment applications, all within a relativ... | |

| Automatic centrifugal disc finishing machine | Areas of application High energy fully automatic centrifugal disc finishing machine is excellent for deburring, surface finishing, edge rounding as... | |

| Vibratory Deburring Machine Tumbler for ball burnishing process | Standard Features: Effective motor position for Excellent Vibration. High tensile bolts and nuts for long service life of motor and machinery. Eff... | |

| Cutlery Polishing Machine-Vibratory Polisher | Standard Features: Effective motor position for Excellent Vibration. High tensile bolts and nuts for long service life of motor and machinery. Eff... | |

| Trough vibrator – Ceramic Exhaust Polishing Machine | Feature: TVB(A) series Trough vibrator machine use curved wall as wall feature, the shape is for better media and parts movement and flow compared... | |

| Vibratory dryer with heating element – Vibratory drier | FUNCTIONAL PRINCIPLE The vibratory dryer generate gentle movement of parts through corn cob or maize During vibratory moisture on surface of parts ... |