ZHEJIANG AOBANG TECHNOLOGY CO.,LTD

Contact information

Zhejiang Aobang Technology Co., Ltd. was established in 2010 and is located in Chengnan Development Zone, Luoshe Town, Huzhou City, Zhejiang Province. It has complete production equipment and sophisticated testing and laboratory. It is a backbone enterprise that manufactures polymer composite molds at home and abroad. With advanced mold making concept, production technology and proprietary application technology, the company enjoys a high reputation in the new energy automobile and motor industry and is a high-tech enterprise in Hangzhou.

The company has a technical team engaged in many years of production and R&D, and has the industry-leading expertise and technical level. We are dedicated to meeting the needs of our customers and highlighting the value that is given to our customers. While determining the performance and specifications of our products, our field service engineers always try to improve the customer\'s profit margin by reducing the actual purchase cost of the customer. We have complete processing and testing capabilities, ISO14001:2004 and ISO9001-2008 management system. Zhejiang Aobang series plastic-sealed DC motor molds and products have won a good reputation among customers with its stable quality, accurate and timely supply and after-sales service.

The high-composite precision molds produced by the company have the characteristics of low energy consumption, no waste, no need to clear the inner cavity, stable mold temperature, small temperature difference, less broken interturn, good appearance and high efficiency. Widely used in new energy vehicles, high-speed rail, electric motors and electrical appliances, it solves the problems of lightweight, leakage safety and aging resistance of automobiles, reduces costs, improves product quality, and corresponds to the low carbon environmental protection policy advocated by the state. The stability and superiority of the products have won the recognition of customers. Our company is well-known enterprises such as Zotye, SKIO, Great Wall, Henan Senyuan, Panasonic, Sanyo, Dayang, Shanghai Kusatsu, Zhuhai Kaibang, Haier, Guangdong Zhigao, Fuji and so on. established and confirmed cooperative relations.

The company\'s commitment to environmental protection runs through the company\'s operating policies and is seen in extensive training and ongoing environmental review. The training opportunities and welfare benefits of employees have been guaranteed the most reliable. The value of each employee in the enterprise has been fully reflected. The concept of corporate ownership is deeply rooted in the hearts of the people.

We never think that sales is the end of a job, because strong technical support and service is the embodiment of our ultimate goal. One of the strengths of our company is the familiarity and mastery of the production system and production environment. We have Experience allows us to provide you with practical solutions and optimized applications.

The company will be based on science and technology, based on management, to provide the best products, quality service, reasonable price for the purpose, in line with the needs of customers and the market, continue to innovate and develop products that are more suitable for customers. We sincerely hope to establish long-term and strong partnership with domestic and foreign businesses and business circles. We hope to gain recognition and support from our customers and to develop mutual cooperation.

Products:

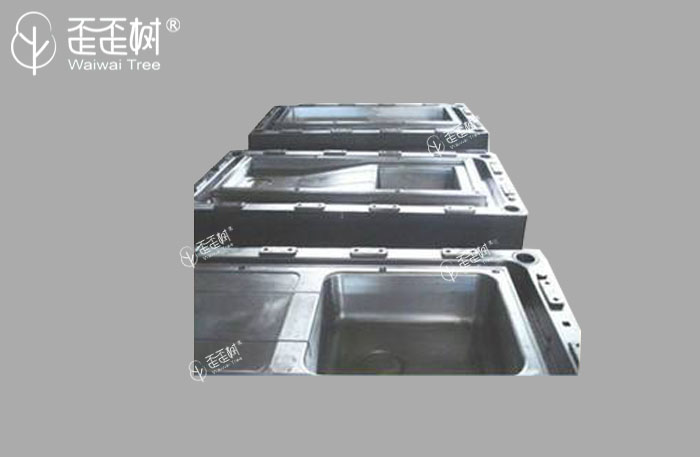

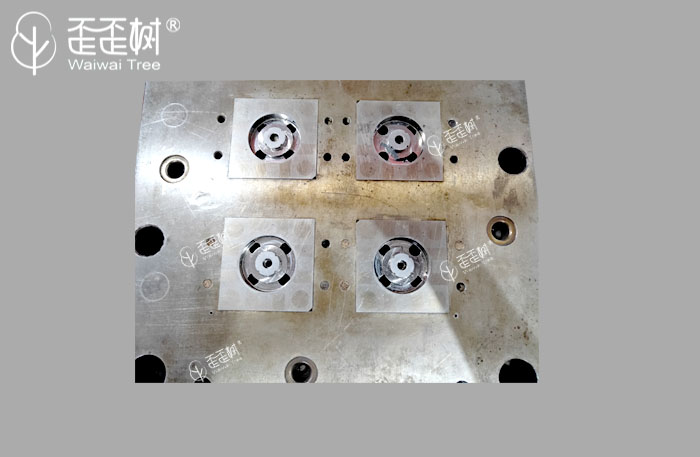

| Household Mould 1104 | Household Mould Description Mainly for pressure molding, the cavity pressure should be considered as small as possible when designing the parting ... | |

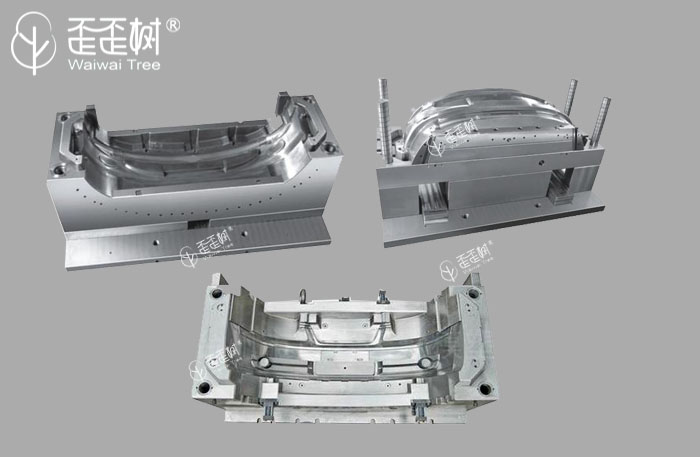

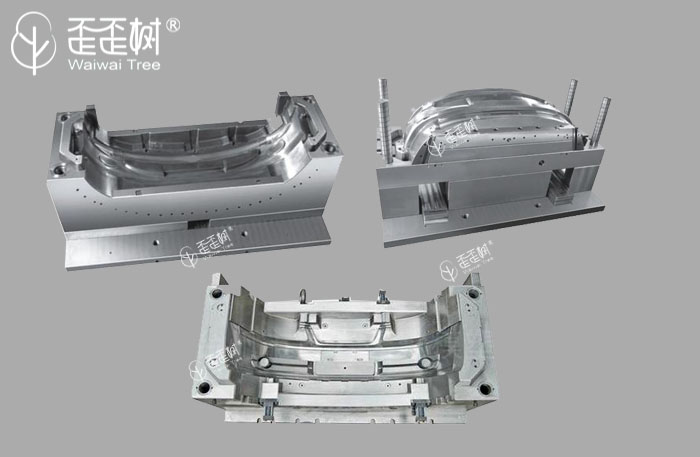

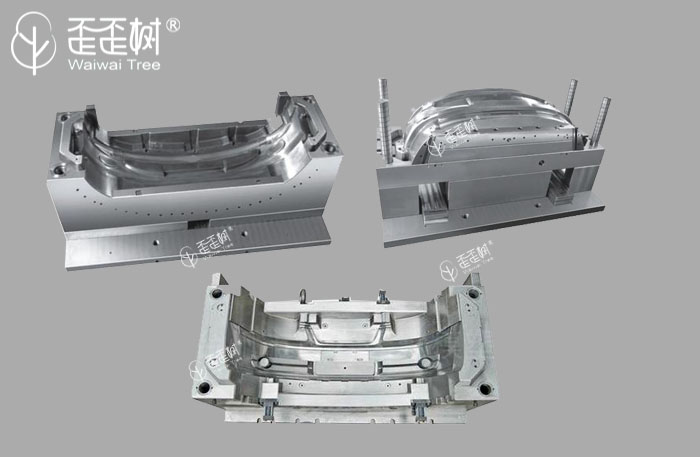

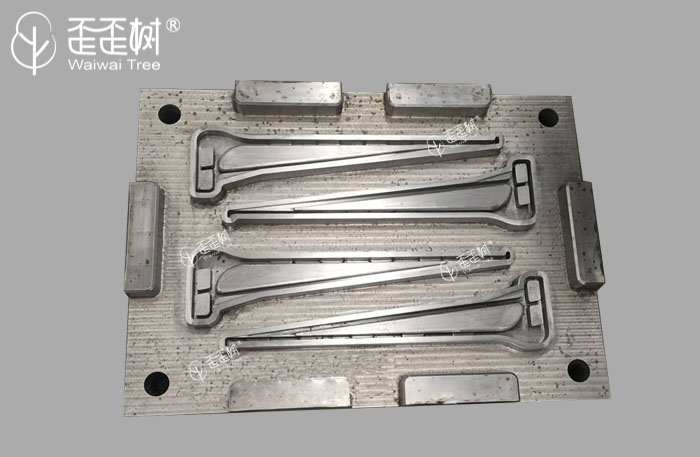

| Auto Parts Mould | Auto Parts MouldFeatures Injection molding and pressure molding are the main methods. When designing the flow channel and parting surface, the cav... | |

| BMC/SMC Mould | BMC/SMC plastic moldingDescription: We mainly use injection molding and pressure molding as the methods. When designing the flow channel and partin... | |

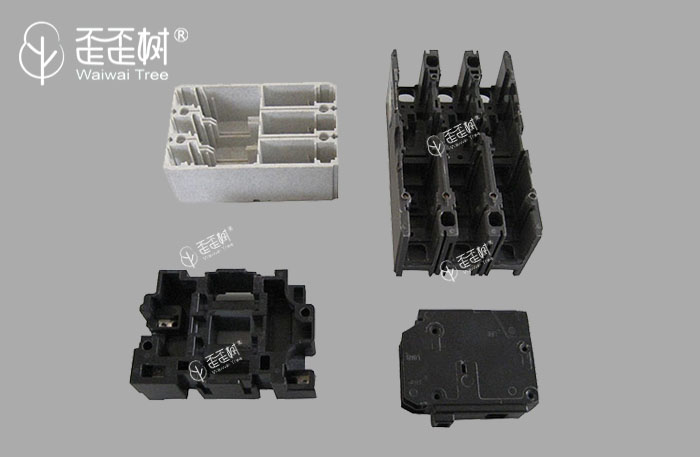

| BMC/SMC Products Description: | SMCBMCthermosetting plastic products are produced by SMC and BMC plastic molding process. What is smc plastic?SMC/BMC is one of thermosetting plas... | |

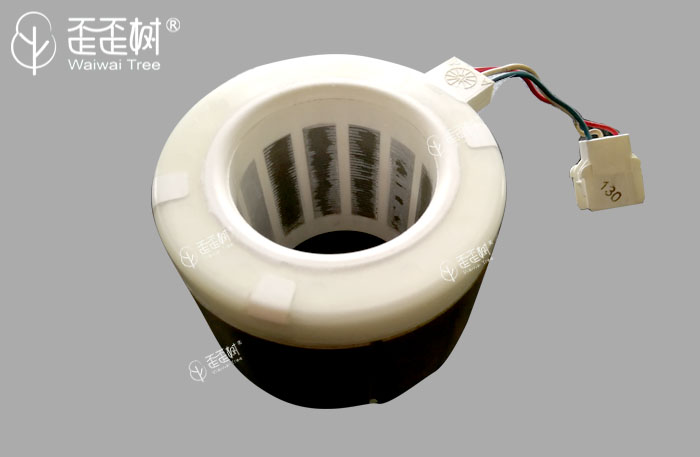

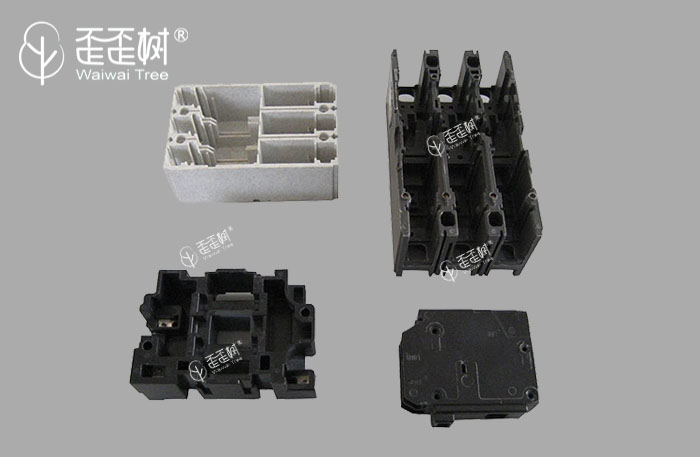

| BMC/SMC Motor | BMC/SMC Motor Description BMC plastic edging motor replaces traditional iron and aluminum, reduces the process, seals more, and has higher safety ... | |

| BMC/SMC Insulation | High-strength, wear-resistant, fire-resistant, color BMC material for medium and low voltage insulators such as SMC Insulated. Typical application... | |

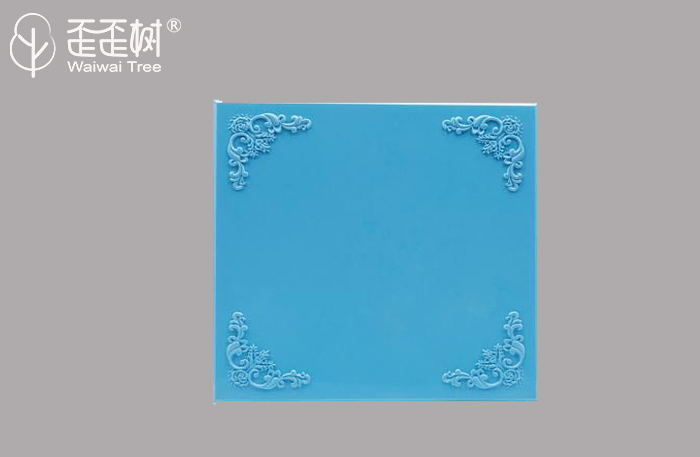

| SMC/BMC Household Goods | SMC/BMC Household Goods Description Including: washbasin, laundry basin, trash can, platen, ceiling. SMC (sheet molding compound) materials are re... | |

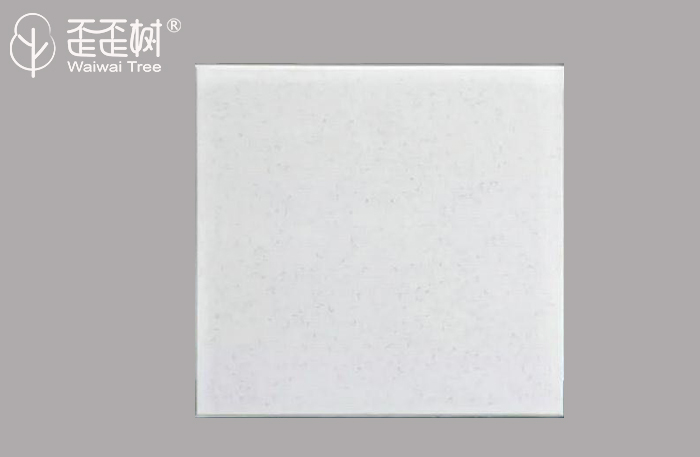

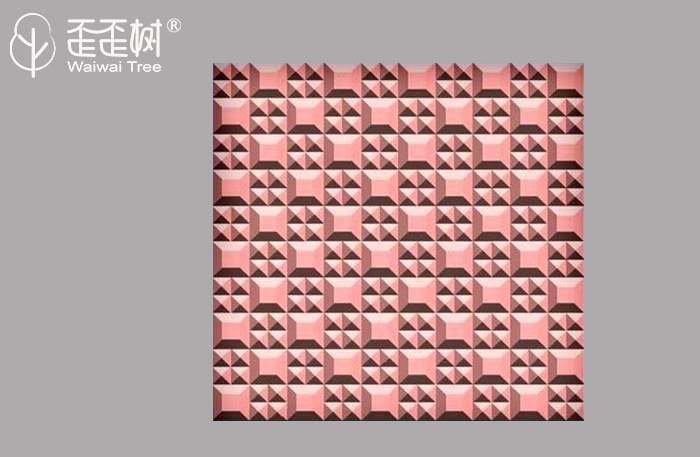

| BMC, SMC, GRP, GFK Wall Panel | Are you looking for smc composite? Aobang composite Wall Panel is divided into: BMC Wall Panel, SMC Wall Panel, GRP Wall Panel, GFK Wall Panel. Co... | |

| BMC, SMC, GRP, GFK Roof Tiles | Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofing tiles, GRP roofing tiles, GFK roofing tiles. Due to the excellent p... | |

| Auto Parts Mould | Auto Parts MouldFeatures Injection molding and pressure molding are the main methods. When designing the flow channel and parting surface, the cav... | |

| BMC/SMC Motor Description | Motor bmcreplaces traditional iron and aluminum, reduces the process, seals more, and has higher safety factor. It mainly refers to white goods and... | |

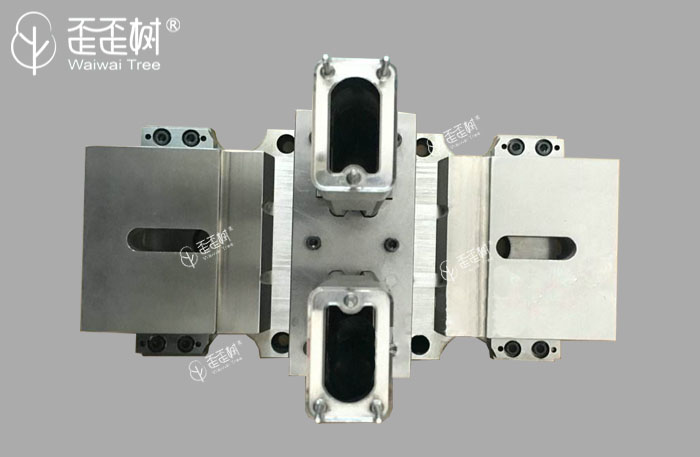

| BMC/SMC Mould | BMC/SMC Moulding Description: We mainly use injection molding and pressure molding as the methods. When designing the flow channel and parting surf... | |

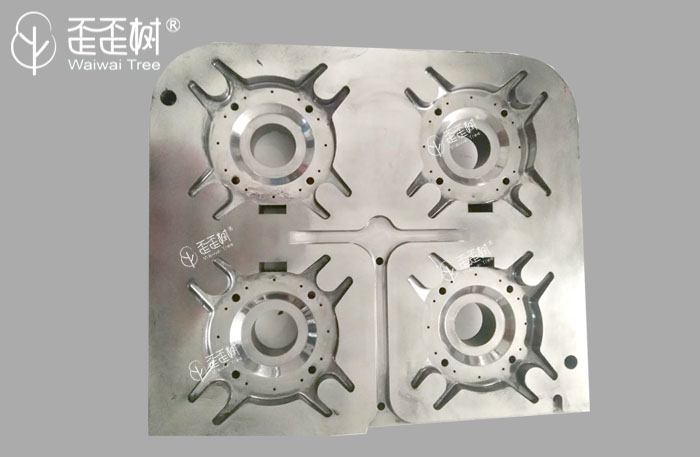

| Flange Molding | Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner and the parting surface. Sinc... | |

| BMC/SMC Products | BMC/SMC Products Description: SMC, BMC thermosetting plastic products are produced by SMC and BMC plastic molding process. What is smc plastic?plas... | |

| BMC, SMC, GRP, GFK Building & Decoration Materials | Aobang composite Building & Decoration materialis divided into: BMC building decoration material, SMC building decoration material, GRP buildin... | |

| BMC, SMC, GRP, GFK Ceiling | Aobang composite ceiling is divided into: BMC ceiling, SMC ceiling, GRP ceiling, GFK Ceiling. The ceiling materials have been developed for more t... | |

| BMC, SMC, GRP, GFK Roof Tiles | Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofingtiles, GRP roofing tiles, GFK roofing tiles. Due to the excellent pr... | |

| BMC, SMC, GRP, GFK Wall Panel | Aobang composite Wall Panel is divided into: BMC Wall seat, SMC Wall Panel, GRP Wall Panel, GFK Wall Panel. Composite Wall Panel the main function... | |

| BMC/SMC Insulation | High-strength, wear-resistant, fire-resistant, color BMC insulationmaterial for medium and low voltage insulators such as SMC Insulated. Typical ap... | |

| SMC/BMC Antenna Reflector | (1) High precision, high efficiency, and high gain. The most important job of using SMC for the manufacture of antennas is to fully exploit its fe... | |

| Auto Parts Mould | Auto Parts Mould Features Injection molding and pressure molding are the main methods. When designing the flow channel and parting surface, the... | |

| BMC/SMC Motor | BMC/SMC Motor Description BMC plastic edging motor replaces traditional iron and aluminum, reduces the process, seals more, and has higher safet... | |

| BMC/SMC Mould | BMC/SMC MouldingDescription: We mainly use injection molding and pressure molding as the methods. When designing the flow channel and parting su... | |

| SMC Antenna Reflector Mould | Mainly for pressure molding, the cavity pressure should be considered as small as possible when designing the parting surface. The exhaust shoul... | |

| BMC/SMC Products | BMC/SMC Products Description: BMC, SMCthermosetting plastic products are produced by BMC and SMC plastic molding process. What is smc plastic?SM... | |

| Automotive Motor | BMC/SMC PRODUCTS BMC/SMC Motor Servo Motor Plastic-Envelop Motor Over Moulding Products BMC Rotor BMC Stator Air Conditioner Motor Refrigerator... |