Hangzhou Roll Forming Machinery Parts Co., Ltd

Contact information

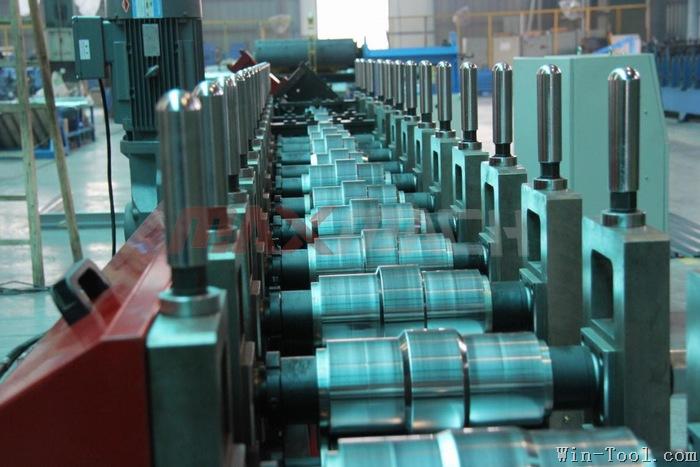

Maxtech registered under the name of Hangzhou Roll Forming Machinery Co., Ltd(which is a Chinese company group engaged in manufacturing, supplying and exporting a wide range of building material machinery such as roll formers). Our group operates through four factories and one operation office in China. Besides, our products are commercialized under three major brands: MaxMach, focused in Roll Forming Machinery, MaxTube, focused in Tube and Pipe Mill Line.and Maxtech focused in sheet metal service. As the following:

MAXTECH as a professional and reliable manufacturer,we are noted for HIGH PRECISION in the sheet metal fabrication industry. We specialize in customizing products according to clients\' drafts and samples. And provide high quality services to our customers and serviced many different industries, including Electronics, Medical, Communications, Rugged Systems , Commercial Industries, Communication equipment, consumer electronics, automation machine,medical device, industrial machine,automobile, electric appliance, and other industries. etc. We provide a wide range of services, which include: 1.sheet metal stamping parts; 2.machinery parts; 3.CNC parts; 4.precision machining service 5.Stamping Dies & Fixtures; 6.Automobile stamping parts; 7.Forklift parts; 8.excavator parts 9.Automobile after sale parts 10.custom cutting service Etc.

Products:

| Strut Roll Forming Machine | Technical parameters Product length: 3000 mm~ 6000 mm Parameters of the raw material:Material Thickness Width I.D. ... | |

| Grain silo roll forming machine | Technical parametersMaterial: GL plateYield strength: 450MpaThickness: 1.0-1.2mmMaterial coil width: 900/950mmLine main parameterLine speed: 3M/M... | |

| 2 Waves Guardrail Roll Forming Machine | Technical parametersRaw Material: Galvanized Sheet, Hot Rolled PlateRaw Material Yield Strength: 235MpaRaw Material Thickness: 2.0 – 4.0mmR... | |

| C post Roll Forming Machine for guardrail | Parameters of the raw material:Material Thickness I.D. Max. O.D. Yield strength Max. coil weight Hot rolled steel 4mm &Osl... | |

| 100 – 600 width Cable Tray Roll Forming Machine | Technical parametersRaw Material: Cold-Rolled Steel, Hot-Rolled SteelYield Strength: 235MpaThickness: 1.0-2.0mmRaw Material Coil Width: According... | |

| 0.8-2mm thickness cable tray roll forming machine | Technical parameterRaw material: cold rolling steel, galvanized steelYield strength: 235MpaThickness:0.8-2mmWidth: as per different specification... | |

| Cantilever Type Cable Tray Roll Forming Machine | Technical parametersRaw Material: Cold-Rolled Steel, galvanized SteelYield Strength: 235MpaThickness: 1.0-2.5mmRaw Material Coil Width: Depends o... | |

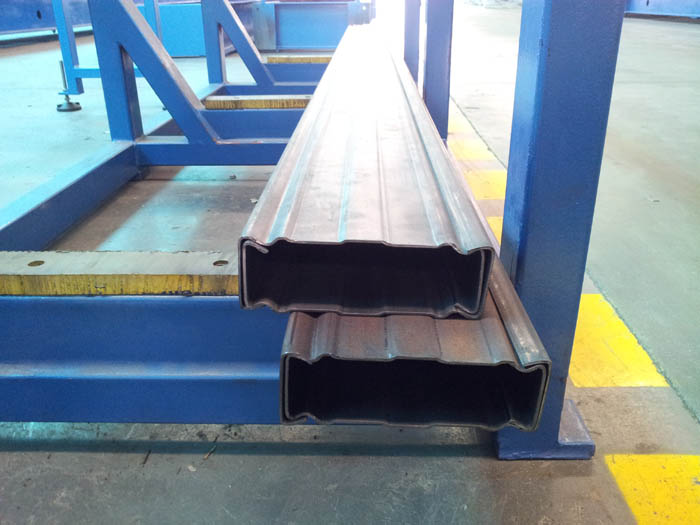

| Floor deck roll forming machine | The surface of Floor Decking Steel Sheet produced by this floor deck forming machine will be smooth without any scratches. The floor decking is w... | |

| Roof tile making machine | This roof tile making machine is always used to produce the color steel or Galvanized steel roof tile.The roof tile making machine is a new gener... | |

| Roofing machine | Roofing machine is mainly used in the production of colored steel sheets. The machine is artistically made and transmits smoothly at a low noise.... | |

| 305 c purline forming machine | Technical ParametersSuitable material Galvanization steel sheet or hr steel strip;Material Spec finds the confirmed profile drawing.Thickness 2&a... | |

| 100 – 250 Z Purlin Roll Forming Machine | 100 – 250 Z Purlin Roll Forming MachineServo Feeding Device (optional)Butt Welding Device (optional)Material Specification:Raw Material: Ho... | |

| 285 Ridge Cap Forming Machine | Technical Parameters1Suitable material Type Colored steel sheetThickness (mm) 0.5-0.55Yield Strength (Mpa) 230-300MpaWidth (mm) 418Wt of the Coil... | |

| 146 Roll Forming Machine for ridge cap | Main Technical Parameter1 Suitable material Type Colored coating steelThickness (mm) 0.55Yield strength (Mpa) 345MpaWidth (mm) 4002 Forming Speed... |