Strut Roll Forming Machine

Technical parameters

Product length: 3000 mm~ 6000 mm

Parameters of the raw material:

Material Thickness Width I.D. Max. O.D. Yield strength Max. coil weight

SS316L,

Cold rolled steel 1.5, 2,

2.5 mm According to the profile Ф508 mm Ф1200 mm ≤400Mpa 3 T

Quality requirements of the raw material

Thickness Tolerance Width Tolerance Steel straightness I.D. Tolerance Material standard

± 0.07 mm +0 mm/-0.2 mm 0.2 mm/m ±15 mm GB

Note

Plate surface unevenness tolerance: ≤10% of the steel thickness)

If the plate with a coating, the coating should be consistent with the coating inspection standards of the relevant color-coated, should not have skin off, so as not to affect the quality of roll forming.

If the material is galvanized steel, the galvanized should be consistent with the relevant testing standards of the galvanized steel, should not have zinc layer off, so as not to affect the quality of roll forming.

Main Technical conditions of the production line:

Temperature: -10℃~35℃

Voltage: 415V, 50 HZ, 3 P

Gas pressure: 0.6~1.2 Mpa

Total gas: 300 L/min

Total power: ≈80 KW

Machine group operation direction: From left to right.

(Facing the operational panel)

Production capacity: 8 m/min (according to the basic length: 3000mm )

Dimension (L*W*H): L≈ 28 m, W≈ 5 m, H≈ 2 m

Specification of the shipping container:(the number is estimated ≈, final data should be confirmed in two weeks before delivery.)

Container 40GP 40OH 40OT 20GP 20OH 20OT

Product process flow:

Decoiling → Levelling → Loop → Servo Feeding → Punching Machine → Loop → Roll Forming

→ Cut To Length → Run Out Table

Send product request

Other supplier products

| CNC lathe turing machined steel and mechanical fabrication | CNC turning is a process by which material is cut to create round shapes, typically using a CNC Lathe. The workpiece is placed inside the lathe a... | |

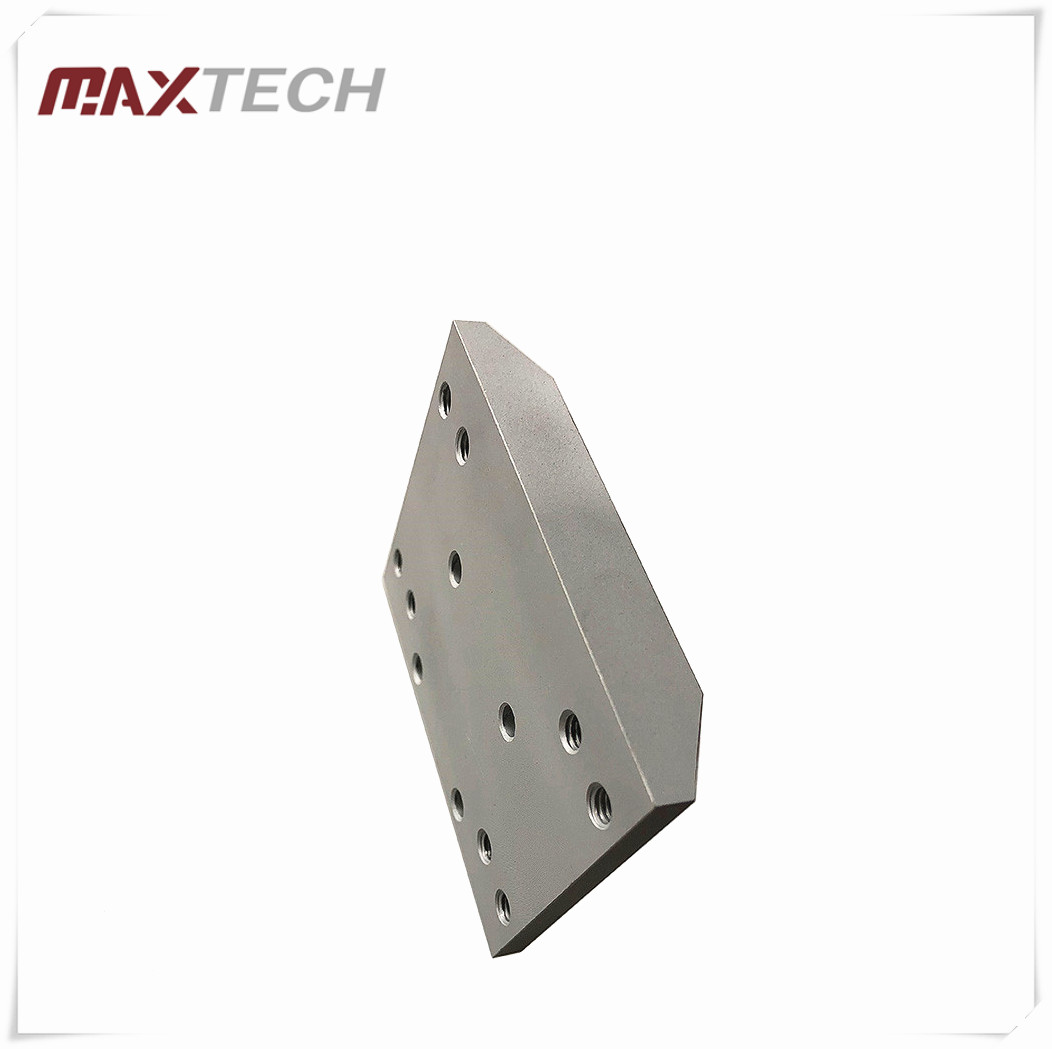

| CNC lathe machining parts | Besides the cnc machining services, we also provide lathe services. We often apply our lathe capabilities to non-bulk orders of parts or hardware... | |

| CNC processing anodized aluminum alloy parts | The CNC processing anodizing aluminum alloy parts are commonly used for a wide range of applications, producing parts that you’ll regularly... | |

| 285 Ridge Cap Forming Machine | Technical Parameters1Suitable material Type Colored steel sheetThickness (mm) 0.5-0.55Yield Strength (Mpa) 230-300MpaWidth (mm) 418Wt of the Coil... | |

| Cantilever Type Cable Tray Roll Forming Machine | Technical parametersRaw Material: Cold-Rolled Steel, galvanized SteelYield Strength: 235MpaThickness: 1.0-2.5mmRaw Material Coil Width: Depends o... |

Same products

| mining filter press | Seller: ZHONG DA BRIGHT FILTER PRESS CO., LTD. | Mining Water Treatment Filter Press Our is designed to efficiently treat and filter water ... | |

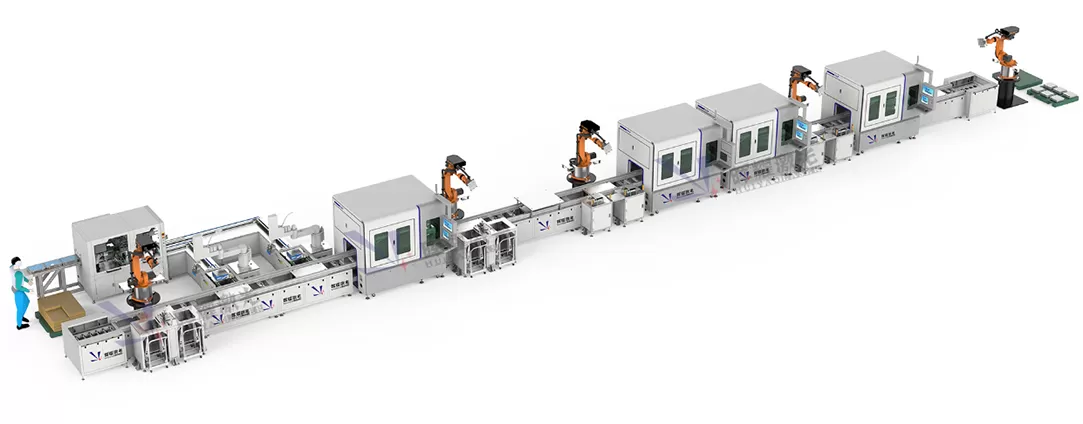

| EV Battery Smart Factory Solution | Seller: Huiyao Laser Technology (Luoyang) Co., Ltd. | EV Battery Smart Factory Solution is an advanced, intelligent manufacturing system designed... | |

| Battery Smart Factory Solution | Seller: Huiyao Laser Technology (Luoyang) Co., Ltd. | Huiyao Laser Battery Module Automation Assembly Line is at the forefront of advanced manufa... | |

| Industrial Steel Pipe Automatic Welding Machine | Seller: Guangdong Shunde Seko Machinery & Technology Co., Ltd | SEKO Machinery industrial steel pipe automatic welding machine specializes in industrial usage, l... | |

| 146 Roll Forming Machine for ridge cap | Seller: Hangzhou Roll Forming Machinery Parts Co., Ltd | Main Technical Parameter1 Suitable material Type Colored coating steelThickness (mm) 0.55Yield ... |