Multi Cavity Mould

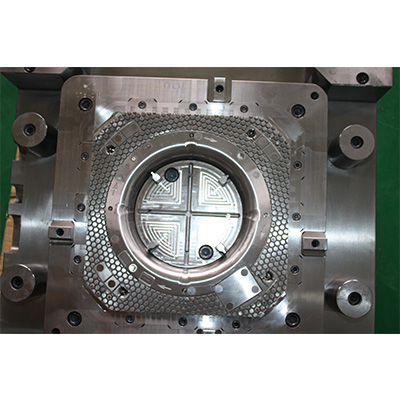

24 Cavities Plastic Injection Mold

Product Name: 24 Cavities Plastic Injection MoldMold Base: LKM, HASCO, DME, etc.Mold Steel: NAK80, ASSAB8407, S136, 718H, 738H, etc. Tolerance: +/-0.002mmFinish: Polish, Silk Screen, Painting, etc.

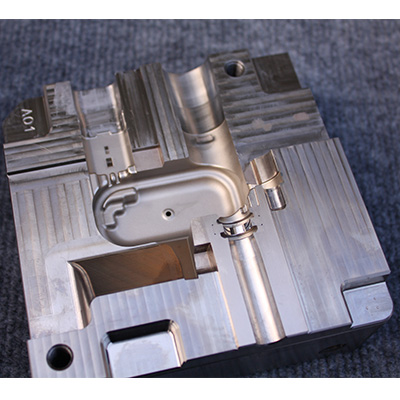

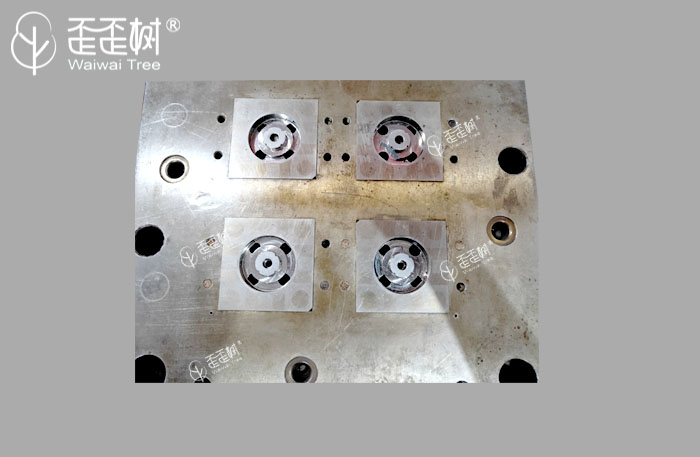

4 Cavities Mould

Plastic Injection Mould standard: DME, HASCO, Meusburger, China LKM Standard etc.Plastic Injection Mold Steel: ASSAB8407/P20/738/2083/2343ESR/NAK80/S136 etc. Mould Base: LKM Mould Base or others.

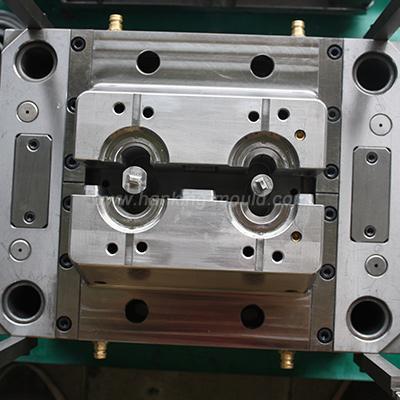

8 Cavities Mould

8 Cavities Plastic Injection Mold to produce plastic ear tag,High volume production mould.Mould Name: Animal Tag MouldPart Material:PPS Product Size: φ15.6Product Description: Animal Plastic TagMould Cavity: 8+8...

8 Cavities Mold

8 Cavities Plastic Injection Mold to produce plastic ear tag, high volume production mould.Mould Name: Animal Tag MouldPart Material:PPS Product Size: φ15.6Product Description: Animal Plastic TagMould Cavity...

8 Cavities Injection Mold

8 Cavities Plastic Injection Mold to produce plastic ear tag,High volume production mould.Mould Name: Animal Tag MouldPart Material:PPSProduct Size: φ15.6Product Description: Animal Plastic TagMould Cavity: 8+8 ...

16 Cavities Mould

16 Cavities Plastic Injection Mold, very high precision plastic mould, important to control the dimension of each cavity insert, the insert is interchangeable.

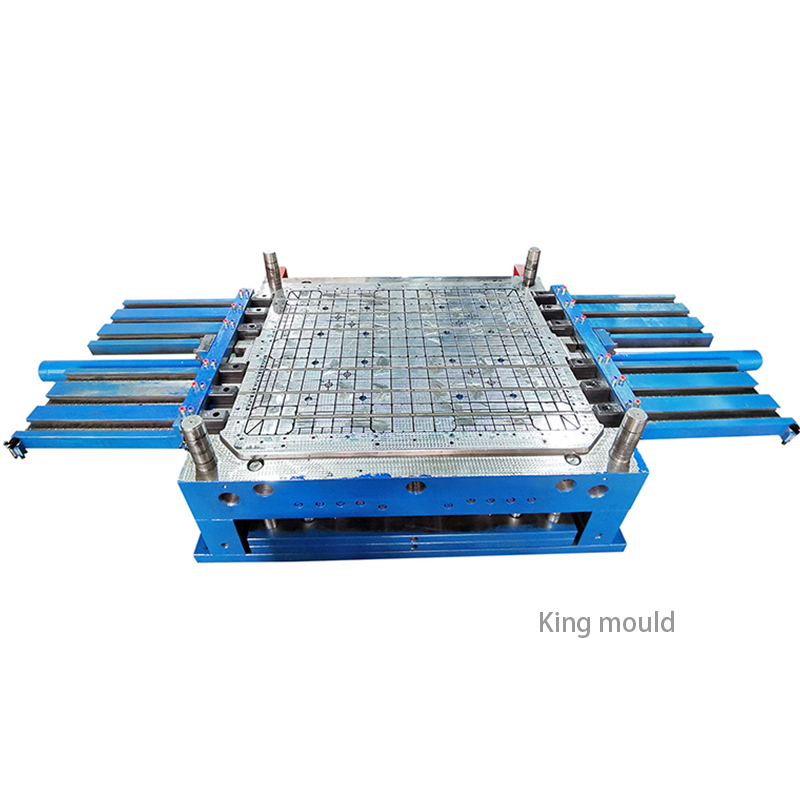

48 cavities mould

Mould Name: 48 Cavities MouldPart Material: PP AV161Product Size: 173.30*34.80*22.87MMProduct Description: C8 RI IBM FORKMould Cavity: 48 CavitiesMould Size: 1000*1400*900 MMSuitable Injection Machine...

A multi-cavity mould can be understood, obviously referring to mold with multiple cavities. The multi-cavity mold comprises a multi-cavity of the same plastic part and a multi-cavity of different plastic parts. The use of multi-cavity molds for injection molding of plastic products can increase production efficiency and reduce costs, so the multi-cavity molds are becoming more popular.

Since the multi cavity mouldmust have multiple runners to supply the melt to each cavity, the rationality of the injection molding system design directly affects the quality of the injection molded parts, material consumption, production efficiency and economic benefits.

In order to ensure the uniformity and performance of the quality and performance of each cavity, the flow balance of the gating system during the injection process is very critical, so that the plastic melt can be filled the cavity with the same pressure and temperature at the same time. Therefore, filling balance is the most important factor to consider when designing a multi cavity mould.

The arrangement of the cavity and the runner is divided into two categories: balanced and unbalanced.

The feature of balance type is the length, shape and section dimension of the runner from the sprue to each cavity are correspondingly the same, it can realize even feeding of all cavities and fill the cavity at the same time. However, the unbalanced feature is that the lengths of the runners from the sprue to the cavity gates are not equal, which is not conducive to balanced feeding, but the unbalanced arrangement can significantly shorten the overall flow of the melt in the gating system. The compact mechanism reduces heat loss and injection pressure loss during flow and shortens the mold filling time.

Related News

The United States Lifts Tariffs On Injection Moulds In China

Four Specific Action Areas for China's Injection Molding Industry

Current Situation Of Injection Molded Parts China Industry

Manufacturing of Dies for Automobile Covering Parts in China

Personalized Customization Becomes the Trend of Manufacturing Industry

Which Plastic Mould Manufacturer is Good in China?

HanKing Mould Enginering Ltd.started the business in the year of 1996 as a custom injection molding chinamakercompany in the line of mold making and injection molding in Longgang, Shenzhen, China.

Send product request

Other supplier products

| Plastic Mould for Air Guiding Fan | With continuous developments and progresses, we have become theprofessional china plastic injection mould manufacturers, offering custom plastic in... | |

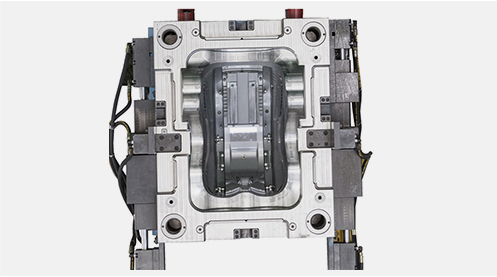

| Precision Automotive Parts | Mould Name: Precision Automotive PlasticsMould Part Material: PA66 G30 Product Description: BODY plastic Mould Cavity: Cavities Mold Mo... | |

| Industrial Molding Parts | Industrial hanking mould parts are referred to the plastic parts of industrial products, HanKing Mould Enginering Ltd.preferred to think of it as n... | |

| Family Mould | As one of the most professional Chinese molding companies, we offer various plastic moldingwith high-quality, such as industrial mouldand so on. F... | |

| Insert Molding Technologies for Automotive Industry | Insert Molding Technologiesfor Automotive Industry Mould Type: Automotive Sensor Plastic Injection Mould Production Material: Nylon PA66 No ... |

Same products

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |