Principle Analysis of Over Moulding Technology for Injection Mold

In the past 10 years, over mouldingtechnology has completely changed the aesthetic standards, design ideas and functional requirements of consumer goods. Medical device manufacturers also recognize the potential advantages of the technology and continue to expand its application in the medical field. Secondary injection moulding technology is famous for creating "soft surface". But it also has many other functions, such as ergonomic design, two-color appearance, brand identification and feature improvement. Using this technology, we can increase the functions of products (such as noise reduction, shock absorption, waterproofing, collision avoidance) and added value. Secondary injection, like co-injection, double injection and sandwich injection, belongs to multi-material injection technology. The basic idea of multi-material injection moulding is to combine two or more materials with different characteristics to improve product value. In this paper, the first kind of injection material is called base material or base material, and the second kind of injection material is called cover material.

In the Over Moulding process, the covering material is injected into the upper, lower, surrounding or inner parts of the substrate to form a complete component. This process can be accomplished by multiple injection moulding or embedded injection moulding. The commonly used covering material is elastic resin.

Establithd in 2010 and located in Chengnan Development Zone, Luothe Tow, Huzhou City, Zhejiang Province, Zhejing Aobang Technology Co. L.d. not only has a mature and extensive prodution line of SMC/BMC compositemoulds but also possesses many refined testing laboratoies in the industry. Whether at home or abroad, Zhejiang Aobang Techmnology Co. Ltd. can manufacture top-qulity SMC BC composites with advanced mold making concepts and technologies. As a professional SMC/BMCmoldingmanufactuer, Waiwai Tree is a hightech enterpise who enjoys a good fame in the new motor and energy automobile industry both at home and abroad.

Send product request

Other supplier products

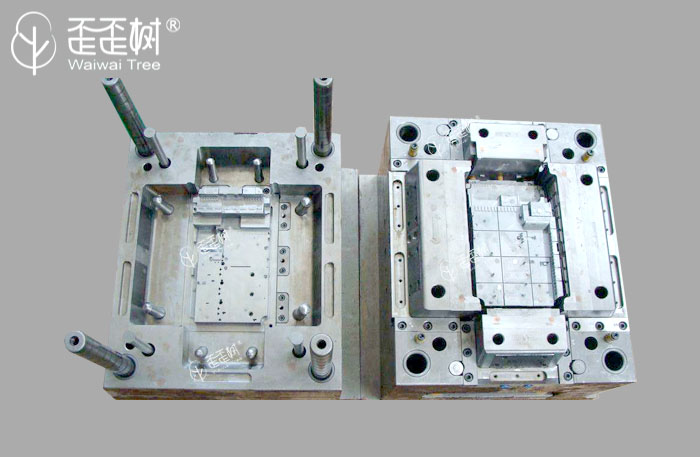

| Household Mould | Household MouldDescription Mainly for pressure molding, the cavity pressure should be considered as small as possible when designing the parting s... | |

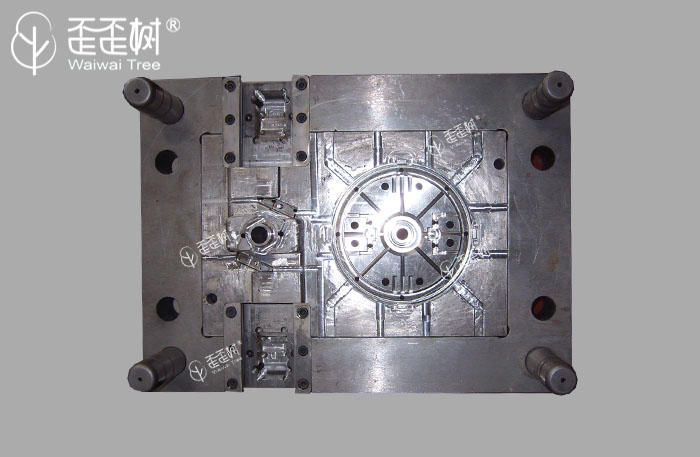

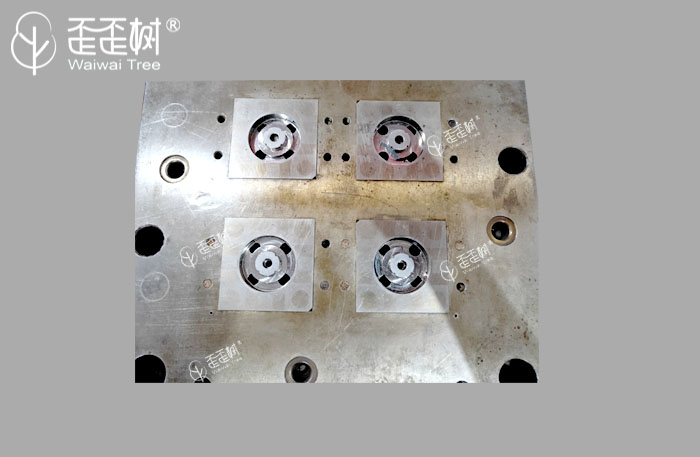

| Motor Mold | Mainly for injection molding, the design of the runner and the parting surface should be as small as possible, and the crossover, exit, protector a... | |

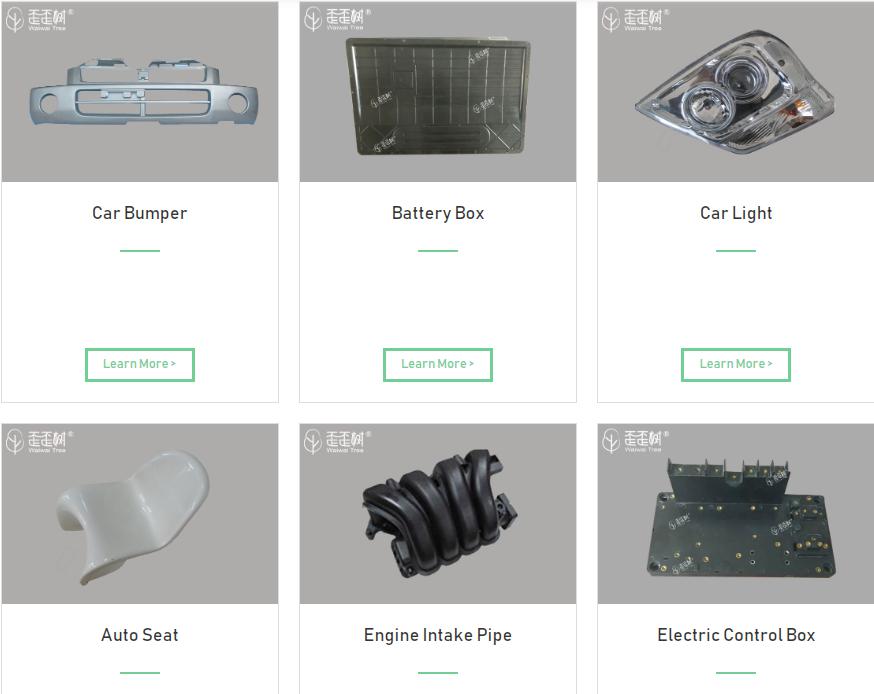

| Auto Parts And Accessories | Auto Parts Description Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the same... | |

| Frame Moulding | Frame Moulding Features Mainly for pressure molding, the cavity pressure should be considered as small as possible when designing the parting sur... | |

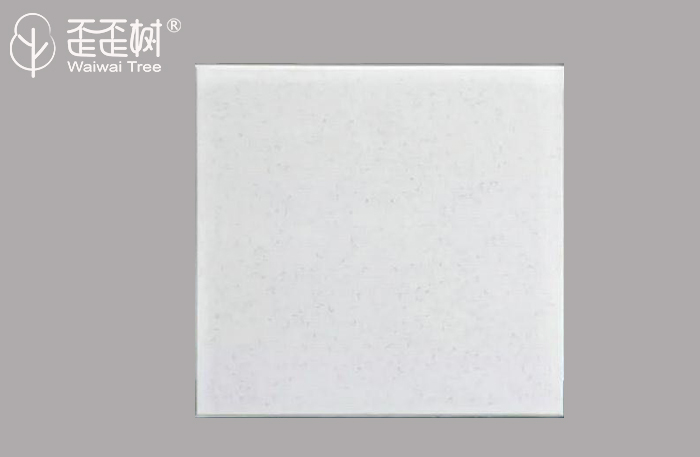

| BMC, SMC, GRP, GFK Roof Tiles | Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofing tiles, GRP roofing tiles, GFK roofing tiles. Due to the excellent p... |

Same products

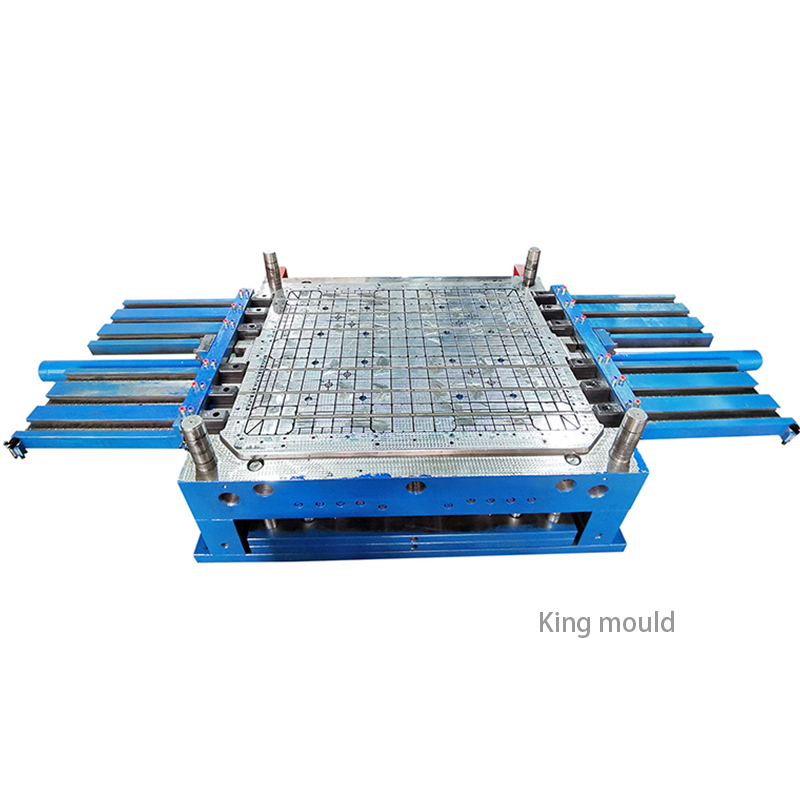

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

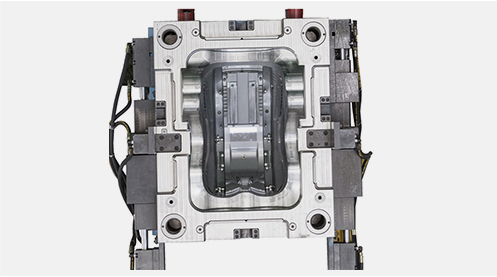

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |