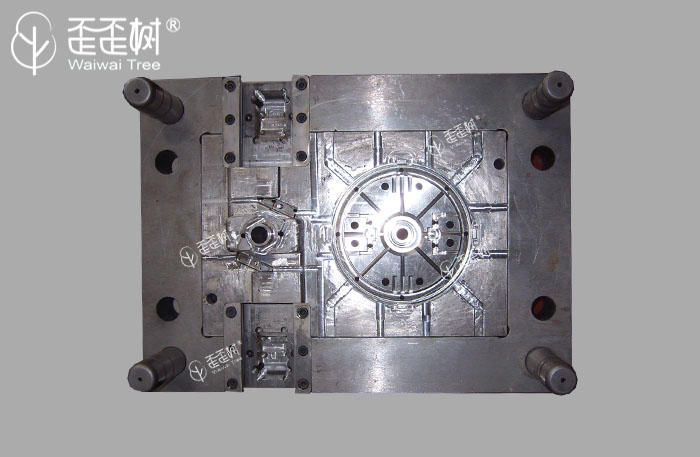

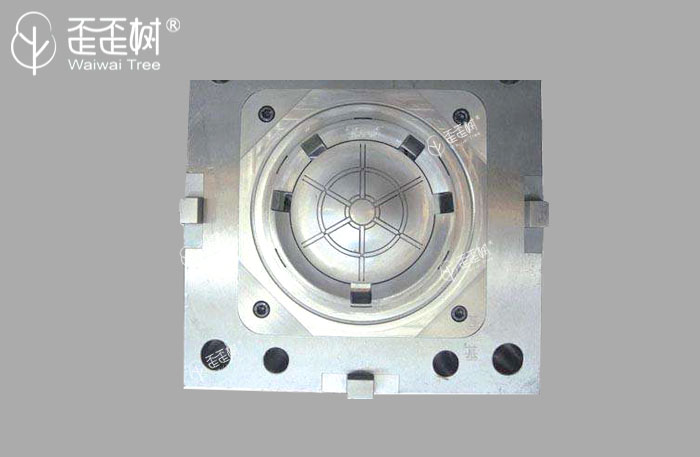

Motor Mold

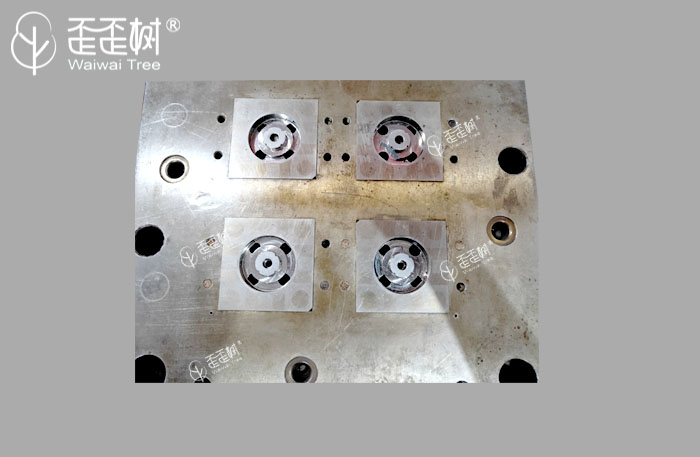

Mainly for injection molding, the design of the runner and the parting surface should be as small as possible, and the crossover, exit, protector and control board of the motor should not be damaged. Because BMC materials cannot be decomposed, we are the first in China without material handle structure. In addition, the inner hole of the motor can be without clearing material. Vacuuming structure, the mold temperature balance is consistent. The appearance and electrical performance of the product are guaranteed.

Motor Mold Supplier

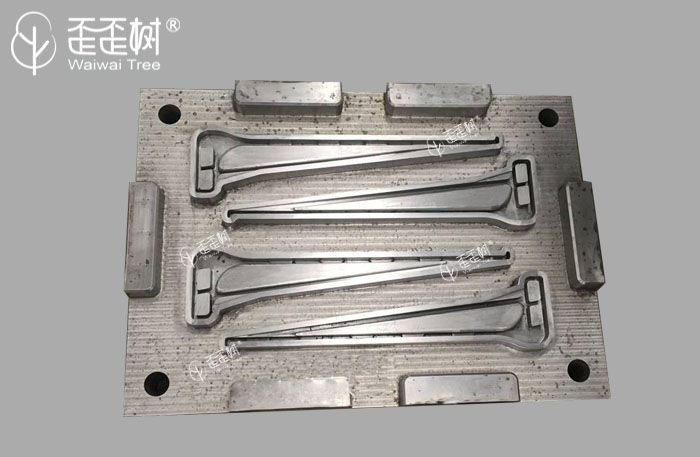

Our motor molds cover a wide range, including: servo motor molds, plastic edging motor molds, plastic encapsulations molds, BMC rotor molds, BMC stator molds, air conditioner motor molds, refrigerator motor molds, washing machine motor molds, DC motor molds, AC motor molds, automotive motor molds, power tool rotor mold, range hood motor mold, motor end cover mold, motor bracket mold, etc.

Motor molds are widely applied. We provide a list of motor molds, including servo motor molds, plastic edging motor molds, plastic encapsulations molds, BMC rotor molds, BMC stator molds, air conditioner motor molds, refrigerator motor molds, washing machine motor molds, DC motor molds, AC motor molds, automotive motor molds, power tool rotor mold, range hood motor mold, motor end cover mold, motor bracket mold, etc. We have customized many types of motor molds for our customers according to their unique and specific requirements.

Factors Deciding the Quality of a Motor Mould

Maintenance cost and maintenance cycle

Quality of motor moldmanufactured: dimensional stability, surface roughness, use ratio of product material

User friendliness, mould release and auxiliary time of production.

Damper Motor Internal Mould

Damper motor is responsible to direct and regulate airflow in zoning system. A functioning damper motor controls airflow of each area. We make customized damper motor internal mould to facilitate your damper motor production.

Aobang provide bmc composite, mold motors, bmc compound, automotive smcmoulding and etc. For more information about bulk molding compound process, please feel free to contact us!

Send product request

Other supplier products

| Development System of BMC Rotor Mould | At present, in the development process of BMC mold, the BMC material is thermosetting resin. In the process of mold heating and curing, because of ... | |

| Flange Molding | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to thermoplastic, thermoset composite can be reproce... | |

| SMC Antenna Reflector Mould | The satellite earth antenna is the important earth satellite equipment to collect the weak signal from satellite and reduce noise to the lowest lev... | |

| Flange Molding | Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner and the parting surface. Sinc... | |

| BMC, SMC, GRP, GFK Wall Panel | BMC, SMC, GRP, GFK Wall Panel Composite wall panel is a new generation of high performance building partition board made of a variety of building ... |

Same products

| Shell Moulding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Shell Moulding Description BMC/SMC shell moulding is mainly injection molded. The application of... | |

| Motor Mold | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Mainly for injection molding, the design of the runner and the parting surface should be as small... |