2k Injection Molding Factory

2k Injection Molding Factory

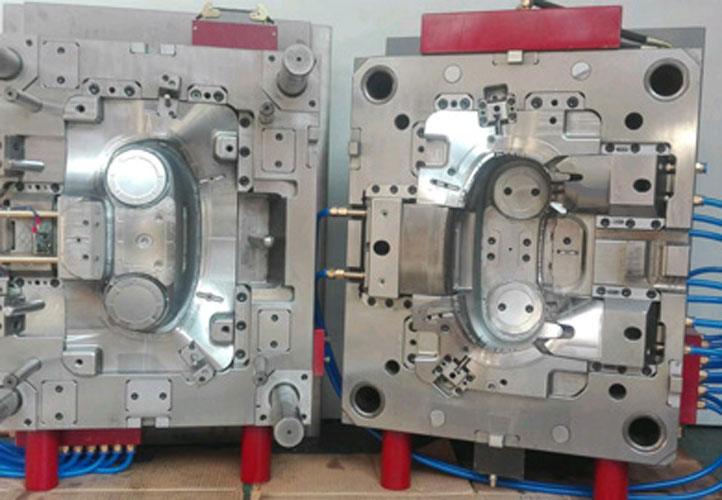

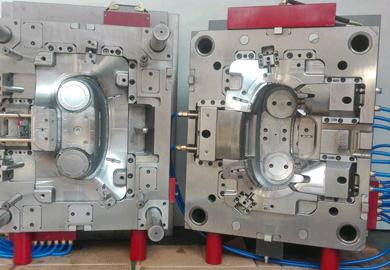

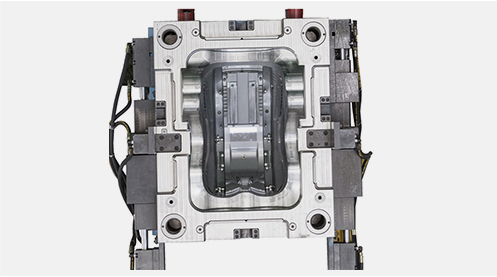

2k injection mouldingis a manufacturing process that refers to molding two materials or colors into one plastic part.

This technology combines two materials or two colors into one ending plastic part by using a 2K automotive custom plastic injection moldingmachine. The selection of the 2K moulding process is generally according to cost and customization considerations.

Features of 2K Injection Moulding Technology

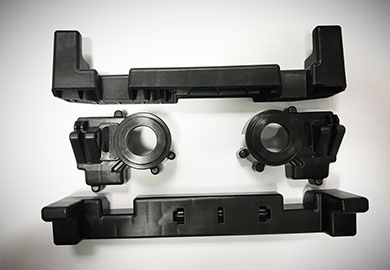

Physical appearance

The physical appearance of 2K injection molding about aesthetic value or beauty is high as many colors can be blended in the molding stages.

Cost-efficiency

Because all 2k mouldingmanufacturing procedures are finished in the injection stage, it can save plastic injection molding cost and lower the labor and material fees.

Customization

We can provide custom-made plastic injection molding products, such as parts&products from appliance plastic molding and screw thread mould to meet your demanding need. It is possible to finish the products with 2K plastic injection mouldingwith softer edges.

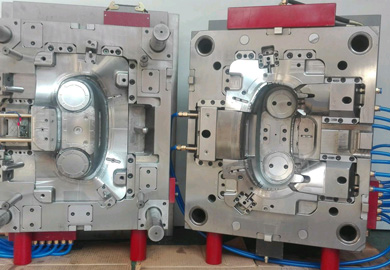

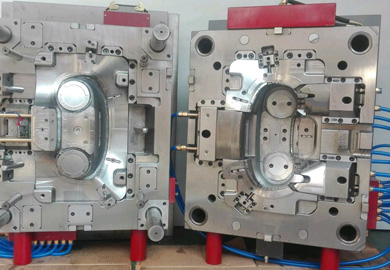

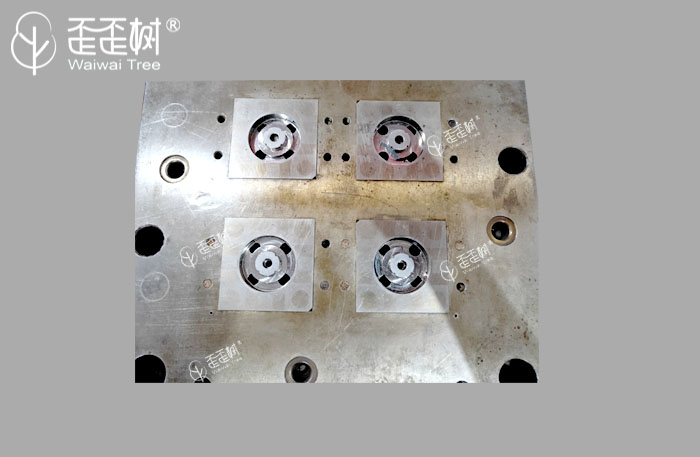

Specification from 2KMouldSupplier

|

Part material |

PC + ABS |

|

Cavity |

1L + 1R |

|

Mold accuracy |

+ / - 0.01 |

|

Mold steel |

|

|

Moldbase steel |

|

|

Mold life |

100W |

|

Mold standard |

HASCO |

|

Mold structure |

6 lifters |

|

Exporting country |

Germany |

|

Delivery time |

4 weeks |

|

Mold quality customer satisfaction |

98% |

|

FAI pass rate |

96% |

|

Project cooperation service customer satisfaction |

98% |

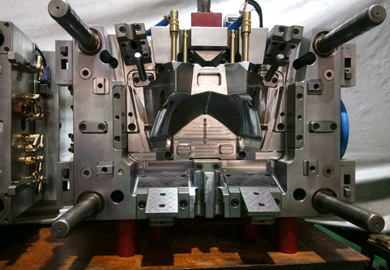

How does 2k Moulding Process Work?

Since there are a lot of benefits of 2K injection molding, can I learn more about the working principle of 2K injection mould?

2K injection moulding operates in one machine which is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The 2K plastic injection moulding is then rotated automatically and another type of plastic is injected from a second nozzle into the mold. When using the 2k injection molding technology process withmould design services, material selection is very important to the injection.

If you want to know more details of mold tech china, please visit our website.

Send product request

Other supplier products

| Electronics Product Mould | Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics ... | |

| Die Casting Mould | Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine. The major adva... | |

| Electronics Product Part | Electronics Product Part With the fast growth in the electronic industry, the demand for injection molding electronicsis much higher. The injectio... | |

| Die Casting | GM-TECH, injection molding supplier,has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. W... | |

| Home Appliance Mould | Household appliances mouldcombines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, h... |

Same products

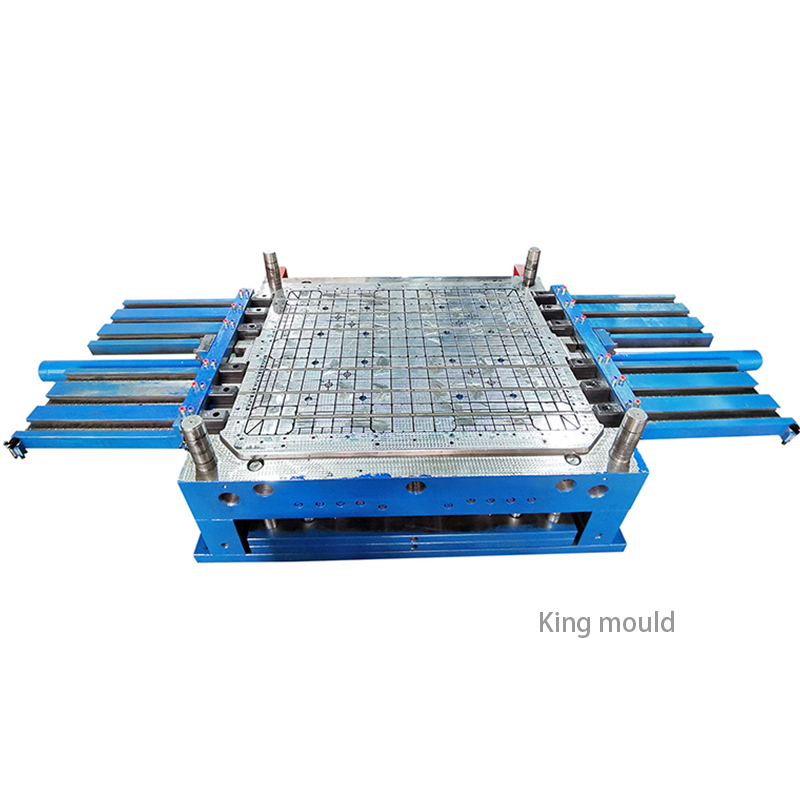

| Plastic Injection Lightweight Pallet Mould | Seller: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Seller: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | Seller: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | Seller: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Seller: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |