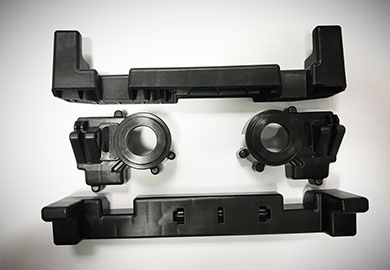

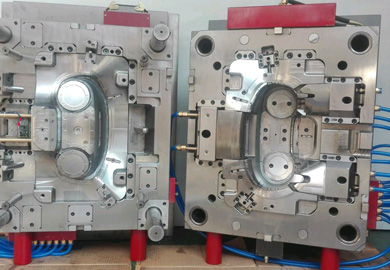

Electronics Product Part

Electronics Product Part

With the fast growth in the electronic industry, the demand for injection molding electronicsis much higher. The injection molding electronics can be intricate or simple.

Intricate injection molding electronics can be economical because they combine many parts into one piece which saves the cost of different types of separate pieces. As a professional electronics plastic manufacturer, GM-TECH provides injection molding electronics such as mobile s, computers, and sophisticated connectors.

Features of injection molding electronics parts

Be able to use a different plastic simultaneously

As a reliable plastic mold technology inc, we can utilize different types of plastic at the same time by using injection molding electronics. This can be achieved with the help of co-injection molding.

Lower the manufacturing cost

Plastic injection moldis an intelligent process with some automatic machines which reduce manufacturing plastic mold cost.

Form the finished appearance

Custom plastic injection molding electronics make sure the parts produced are near to the finished produces. Thus, it hardly takes any time to arrange the rest of the work.

The Specification of injection molding electronics Product Part

|

Part material |

PA66 + 30gf |

|

Cavity |

1 |

|

Mould steel |

|

|

Mould steel |

|

|

Mould life |

100W |

|

Mould standard |

HASCO |

|

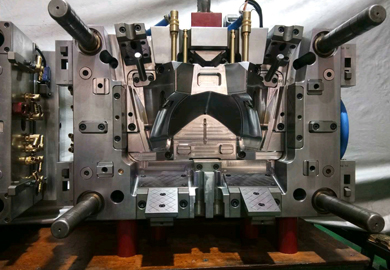

Mould structure |

3 sliders |

|

Exporting country |

Germany |

|

Leadtime |

5 weeks |

|

Mould quality customer satisfaction |

96% |

|

FAI pass rate |

99% |

|

Project cooperation service customer satisfaction |

98% |

How do Injection Molding Electronics Parts Work?

The series of events that occur during the injection molding electronics molding process is called the injection molding cycle. When the mold is closed, the polymer of plastic molded products is injected into the mold cavity. Once the cavity is filled, the pressure is maintained to compensate for the shrinkage of the plastic injection molded part material. In the next step, the screw rotates to give the screw before the next lens. This allows the screw to retract when preparing for the next stitch. Once the part is sufficiently cooled, the mold opens and the injection molding electronics are ejected.

Send product request

Other supplier products

| Mould Design | GM-TECH have a much experienced design team, familiar with China domestic, European, American, Japanese and other mold design standards, be able to... | |

| Die Casting Mould | Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine. The major adva... | |

| Electronics Product Part | Electronics Product Part With the fast growth in the electronic industry, the demand for injection molding electronicsis much higher. The injectio... | |

| Electronics Product Mould | Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics ... | |

| Electronics Product Mould | Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The in mould ele... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |