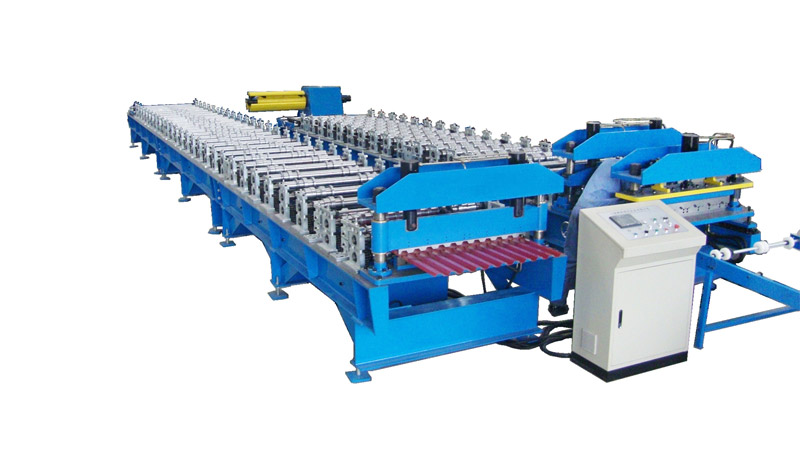

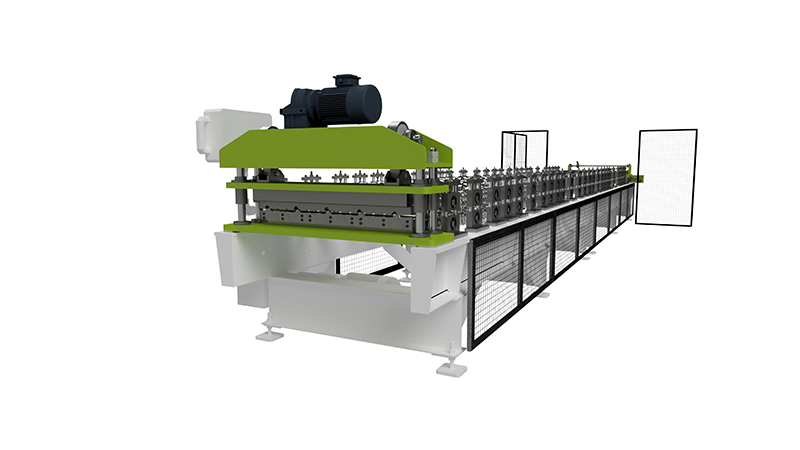

Roof Panel Roll Forming Machine

This metal cladding roll forming machineis used to roll-form metal roof panels and metal wall panels. The roll forming line usually includes metal decoilers, forming devices, output support table. The machines for popular profiles are available from stock. Our roll forming machine can also be customized and manufactured according to the customers' profile drawings.

Features and Advantages of Roof Panel Roll Forming Machine

Specially designed for forming roofing corrugated sheet, siding panel, floor decking, under mass-production.

Production speed: 20/30/40/50/60 m/min optional.

Working with a non-stop flying cut and full automatically stacking system, Max speed of the line can reach 60 m/min.

Cassette-type platform quick-change Machine base for multi-profile purposes is available for choice.

Certified with Multi-Patents; CE Certified, EUROPEAN quality standard

For most of the hot & popular profiles models, we have ready roof and wall panel roll forming machine in stock for prompt delivery.

Raw Materials for Roof Panel Roll Forming Machine

Suitable material: Colored/ Stainless/Galvanized Steel, Aluminum sheet

Thickness: 0.3-0.7(mm)

Yield Strength: 230-300/350/550-675(MPa) (optional)

Width: 1200/1220/1250(mm)

Roofing Sheet Roll Forming MachineProduction Line Components and Parameters

|

Decoiler |

5t/8t/10t/15t Motor/hydraulic motor/passive (optional) |

|

Filming covering device |

optional |

|

Front shear |

optional |

|

Lubricating device |

no need |

|

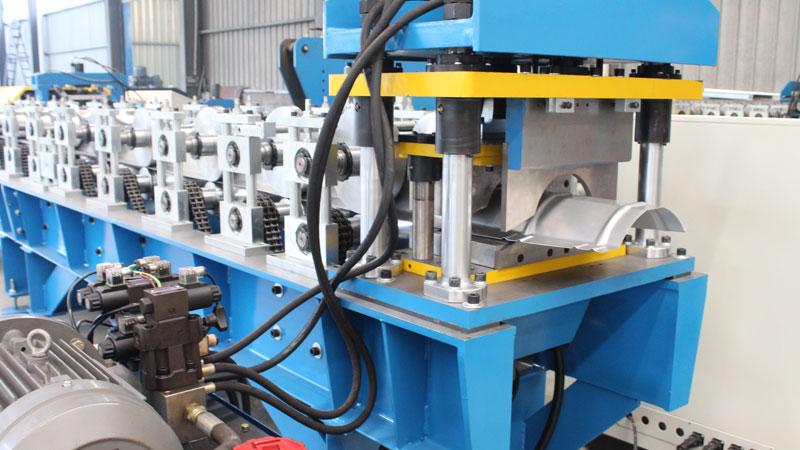

Roll forming system |

20/30/40/50/60 m/min (optional) |

|

Safety cover |

optional |

|

Post cutting |

Motor/hydraulic (optional) |

|

Output System |

Manual supporter/ Automatic Stacker (optional) |

|

Stackmaster |

(Output direction) Lateral/Longitudinal (optional) |

|

Hydraulic system |

Power supply for decoiler /post-cutting system |

|

Electric control system |

MITSUBISH/ SIEMENSE/AMS (optional or as requested) |

The Working Process of Roof Panel Roll Forming Machine

This series of roof cladding roll forming machinewill go through the following working procedures: Coil Charging Car(optional) - Decoiler(passive/auto) - Front Shear(optional) - Feeding and Guiding Table - Filming Covering (optional) - Roll Forming System- Post-Cutting to length (Hydraulic/Motor) - Output Manual Supporter/Stackmaster(optional)

Applications of Roof Panel Roll Forming Machine

This series of the profile is designed to be economical wall cladding for residential, industrial, and commercial projects.

A minimum of 0.30mm and a maximum of 0.7mm gives more resilience to damage.

Specifications of Roof Panel Roll Forming Machine For Sale

|

Machine Condition |

Fully New, A-Grade quality |

|

Panel Shape |

As profile drawing and customer's requirements |

|

Operator needed |

1-2 persons |

|

Power Supply |

220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 15t |

|

Dimension |

(L*W*H) about 25*3*2m |

|

LOADING SIZE |

Normally need 1x 40' (+ 1x 20GP) container |

|

Equipment Color |

Normally Blue/White, or as requests |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

As a professional tube mill supplier, we provide roll forming equipment for sale, roll forming machineand etc. Contact us to know roll forming machine specificationor buy our tube mill equipment.

Send product request

Other supplier products

| AG PANEL ROLL FORMER | This ag panel roll forming machineseries is used to make high-quality AG panels. As a professional roof and wall panel roll forming machine manufac... | |

| Ridge Cap Roll Forming Machine | The series of ridge cap forming machineare mainly used to make ridge capping. Ridge capping is a critical part of the structure of a roof. Ridge ca... | |

| Double Layer Roll Forming Machine | Double layer cold roll forming machine, also called double deck roll forming machine. To meet the requirements for roll forming two different profi... | |

| C Purlin Roll Forming Machine 202108 | The C purlin roll forming machine produced by Hangzhou Roll Forming Technology is manufactured with advanced technologies. Not only does this serie... | |

| API PIPE MILL FOR OIL TRANSPORTATION | API Pipe Mill For Oil Transportation is a series of machines that build longitudinal weld seam tubes and pipes with steel strips of certain width. ... |

Same products

| Wide-Mouth Mold | Seller: Taizhou Qihong Mold Co., Ltd. | A Wide-Mouth Mold is a specialized mold used to produce containers with a wider opening, often fo... | |

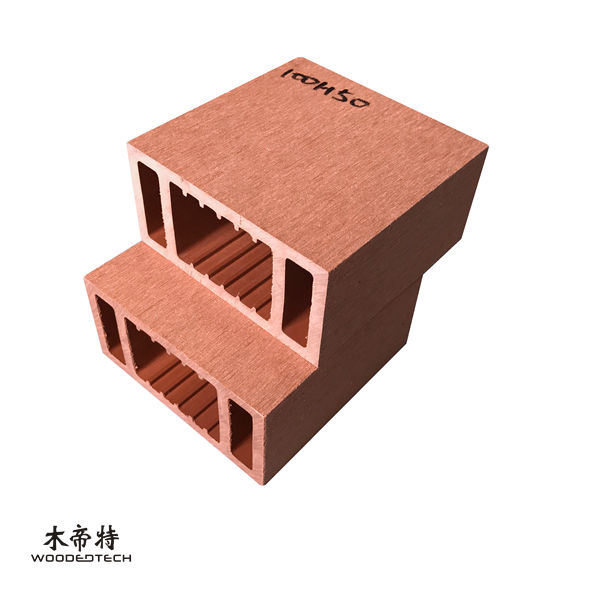

| High-Quality outdoor Custom Wood Plastic Composite (WPC) Square Handrail from China – Durable & Stylish Railing Solution | Seller: Guangzhou woodedtech Co.,Ltd | Product Description: L10050 Wood Plastic Composite (WPC) Square Handrail Elevate your outdoor sp... | |

| Molybdenum Electrode | Seller: Baoji City Changsheng Titanium Co.,Ltd | Molybdenum electrodemade by powder metallurgy technology with pure molybdenum powder has high mel... | |

| PTFE Braided Packing | Seller: Jiangsu Xinrui Plastic Technology Co.,Ltd | PTFE braided packingis a new type of sealing packing with desperse Teflon tape or tensile belt af... | |

| Molybdenum Boat | Seller: Longhua Technology Group (Luoyang) Co., Ltd | Molybdenum boats are small, boat-shaped containers made of pure molybdenum or molybdenum alloys, ... |