Roof And Wall Panel Roll Forming Machine

The cold roll forming machine is the equipment for continuously processing metal sheets of a coil, a strip, by a multi-pass forming roller which is a plastic processing process to form a specific section profile.

Hangzhou Roll forming Trecinogy Co.,Ltd is a professional roof panel roll forming machine manufacturersand exporter of all kinds of standard and nonstandard roll forming machinery. We offer various sheet metal and coil metal roll forming machines such as shelf and roll forming machines, downspout roll foming machines, double layer roll forming machines with the reliable process, high productivity, high reliability.

Our roll forming equipment consists of decolier machine, feeding table, guiding equipment, roll forming system, post-cutting system (electric o hydraulic), controlling system and hydraulic station. Wide variety of cold-formed steel, from the sub-section shape, with open, semi-closed and closed, the main products of roll forming machine are cold-formed channel steel, angle steel, Z section steel, cold-formed corrugated steel, pipe, square tube, rectangular tube, welded tube-shaped, rolling shutter doors and so on. Steel cross-section shape can be designed: size, accuracy, and length can flexibly be adjusted according to need, all supplied by length or double length, improve maternal utilization. Production processes can also be matched with the punch, so as to meet different requirements.

Roof and Wall Panel Roll Forming MachineSpecification

|

Metal Decoiler |

Cantilevered TypeHydraulic ExpandingzHydraulic ReleasingWith Light controlSeparate Hydraulic station and control |

|

Guiding device |

Adopting a guiding bar and sliding block to control the width and position of the steel sheet. The sheet is guided in the correct position and runs to the roll forming equipment. |

|

Roll Forming System |

|

|

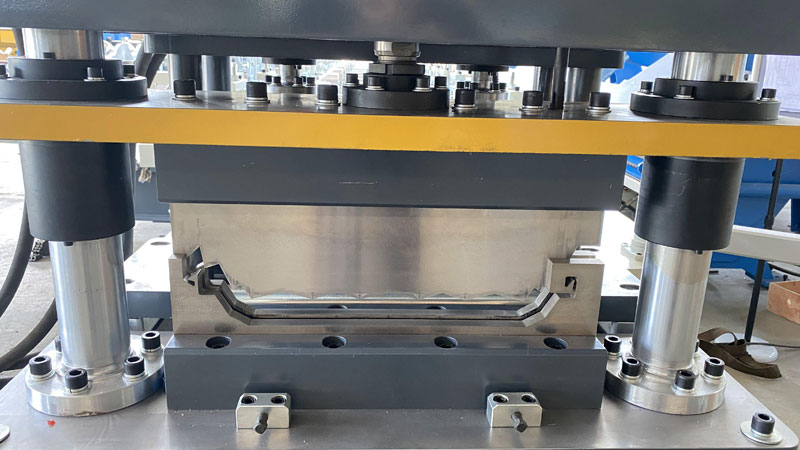

Punching die and Cutting Device |

|

|

Product Supporter |

To support the finished panels manually and the length of each piece is 2 meters, two pieces. |

|

Electrical Control System |

With PLC control and frequency speed adjusting technology to realize the automatic production1. The system provides a good interface screen for the roof forming machine, which can set the batches, plate length, and quantities. |

|

Hydraulic Station |

|

Roof And Wall Metal Roof Tile Making Machine FAQs

How thick plate can your panel roll forming machineforming?

Normally the thickness of the roof/wall panel ranges from 0.23mm to 1mm. If customers want to make the thicker panels, we can also design the machine.

What kind of roofing panel can your roof panel machine make?

Our roll forming machine linemakes trapezoidal panels, corrugated panels, standing seam panels, metal roof tiles, AG panels, PBR panels, ridge capping and so on. We also design and manufacture rolling line according customers' profile drawings.

Are your panel forming machinein stock?

We have some popular rolling machines in stock. It takes about 45 days if customers need customize machines.

Can you make metal roof tile making machine according to customers' profile drawings?

We can design and manufacture metal roof tile making machines according to customers' own profile drawings. It takes about 45 days if customers need to customize machines.

Can your roof panel machineforming aluminum panel?

We can design and manufacture rolling line for aluminum panel.

Send product request

Other supplier products

| AG PANEL ROLL FORMER | AG panel roll formeris a machine used in the manufacturing process of metal roofing panels. The machine is used to shape flat metal sheets into a c... | |

| C Purlin Roll Forming Machine 202108 | The C purlin roll forming machine produced by Hangzhou Roll Forming Technology is manufactured with advanced technologies. Not only does this serie... | |

| Single Side Manual Decoiler | SINGLE SIDE MANUAL DECOILER Specifications ofSingle Side Manual Decoiler Capacity 2t/2.5t/3t/5t is optional Extension m... | |

| Coil Embossing Machine | As a professional embossing machine supplier, we provide tube mill line, roll forming machine, china square tube making machine, electric embossing... | |

| Standing Seam Roll Forming Machine | Our company, Hangzhou Roll Forming Technology Co., Ltd, is a China stainless steel tube mill manufacturer and pipe mill China. This machine make st... |

Same products

| Wide-Mouth Mold | Seller: Taizhou Qihong Mold Co., Ltd. | A Wide-Mouth Mold is a specialized mold used to produce containers with a wider opening, often fo... | |

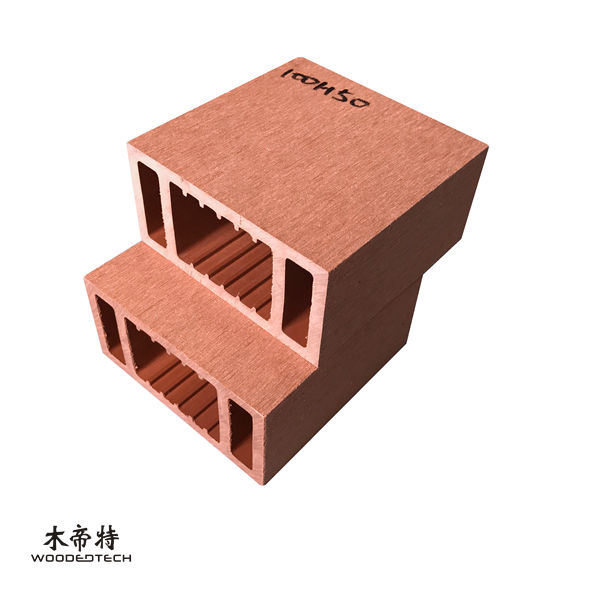

| High-Quality outdoor Custom Wood Plastic Composite (WPC) Square Handrail from China – Durable & Stylish Railing Solution | Seller: Guangzhou woodedtech Co.,Ltd | Product Description: L10050 Wood Plastic Composite (WPC) Square Handrail Elevate your outdoor sp... | |

| Molybdenum Electrode | Seller: Baoji City Changsheng Titanium Co.,Ltd | Molybdenum electrodemade by powder metallurgy technology with pure molybdenum powder has high mel... | |

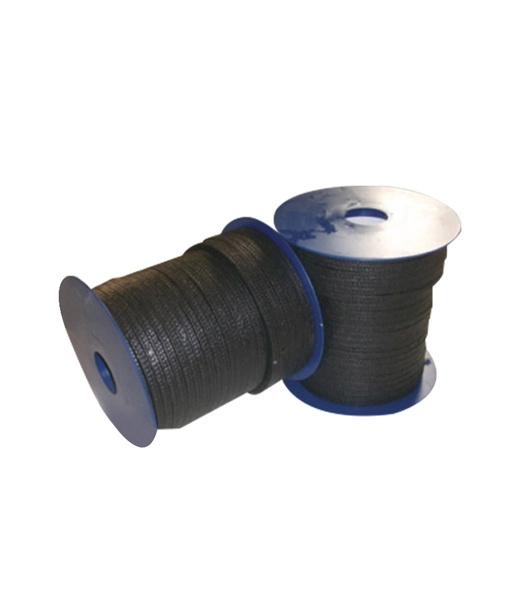

| PTFE Braided Packing | Seller: Jiangsu Xinrui Plastic Technology Co.,Ltd | PTFE braided packingis a new type of sealing packing with desperse Teflon tape or tensile belt af... | |

| Molybdenum Boat | Seller: Longhua Technology Group (Luoyang) Co., Ltd | Molybdenum boats are small, boat-shaped containers made of pure molybdenum or molybdenum alloys, ... |