Drum Fly Shear for Cold Rolling Mill

Drum Fly Shearfor Cold Rolling Mill

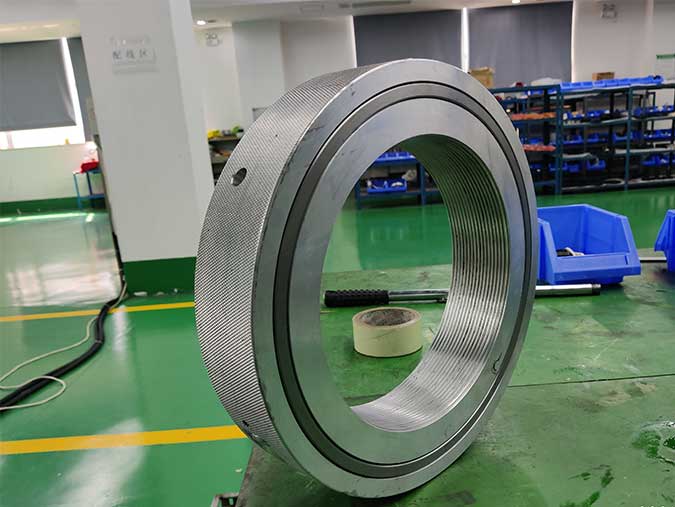

Drum flying shears are used at the exit of various continuous cold rolling mills for strips to realize dynamic sub-coiling. During the shearing process, the upper and lower drums of the flying shears make circular motions, and the shear blades installed in the drums perform shearing motion with the rotation of the drums to cut the strip. The flying shear in rolling millcan automatically or manually adjust the side clearance of the cutting blade through the adjustment device to meet the cutting needs of different specifications of strip steel.

Application Scope of Drum Fly Shear for Cold Rolling Mill

This type of drum flying shear machineis suitable for pickling mill combined group, full continuous cold rolling group, used for dynamic slitting of strip steel, and also used for strip head and tail cutting, according to the set coil weight, and according to the set length Cut to length and accident cutting.

|

Material |

Strip thickness |

Strip width |

Tensile strength |

Shear rate |

|

carbon steel, stainless steel |

500-1600mm |

≤850MPa |

≤260m/min |

Structure Advantage of Drum Fly Shear for Cold Rolling Mill

Roller-type shearing blade arrangement and helical gear anti-backlash mechanism at the same time can greatly improve the accuracy and stability of the equipment.

According to the technological requirements, the cutters can be arranged with single or double cutting edges and straight cutting edges or oblique cutting edges.

According to different strip thickness and strength, the cutting blade gap can be adjusted automatically or manually to improve the cutting quality and tool life.

Electromechanical and hydraulic control integrated products, equipped with reliable Siemens control system and optimized process adjustment template, can effectively ensure stable product quality.

If you want to know more about steel plant finishing line, please visit our website.

We also have types of coil cutting machinefor sale, more details, please leave us a message.

Send product request

Other supplier products

| Tension Leveler for Galvanizing Line | Galvanizing line tension leveler is a continuous stretching bending straightening machine that is used in the continuous hot-dip galvanizing line. ... | |

| CV Joint For Steel and Non-ferrous Metal Industries | CV Joint For Steel and Non-ferrous Metal Industries The main product is ball cage type, designed and developed BJ, BHJ, BJS, BC, DOJ five categori... | |

| Fine Blanking Line | Based on BOYA's excellent processing and manufacturing capacity and rich series of products, we have a complete set of fine blanking equipment for ... | |

| Hydraulic Nut | Hydraulic nutis a strong fastening component, it is a special nut that integrates a hydraulic device on the nut body and locks the connecting objec... | |

| Drum Fly Shear for Cold Rolling Mill | Drum flying shears are used at the exit of various continuous cold rolling mills for strips to realize dynamic sub-coiling. During the shearing pro... |

Same products

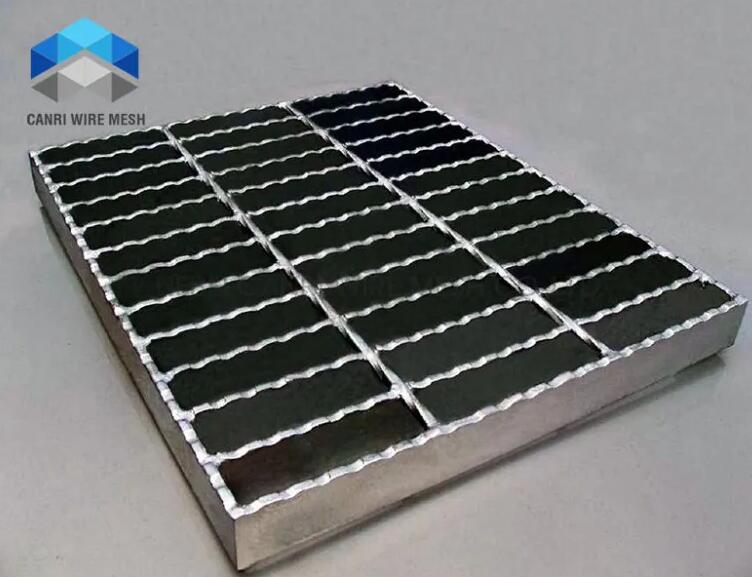

| Galvanized Steel Grating for Drainage | Seller: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating for Drainage Steel gratingfor drainage, also known as galvanised draina... | |

| Floor Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Floor Grating Floor grating, also known as open grid flooringor bar grating, is a type of structu... | |

| Serrated Bar Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Serrated Bar Steel Grating Steel bar gratinghas two surface type: serrated surface and smooth su... | |

| Stainless Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Stainless Steel Grating Stainless steel gratinghas been the standard industrial foot walk produc... | |

| Galvanized Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating Galvanized steel gratingis an ideal product for wet, slippery situation... |