Tension Leveler for Galvanizing Line

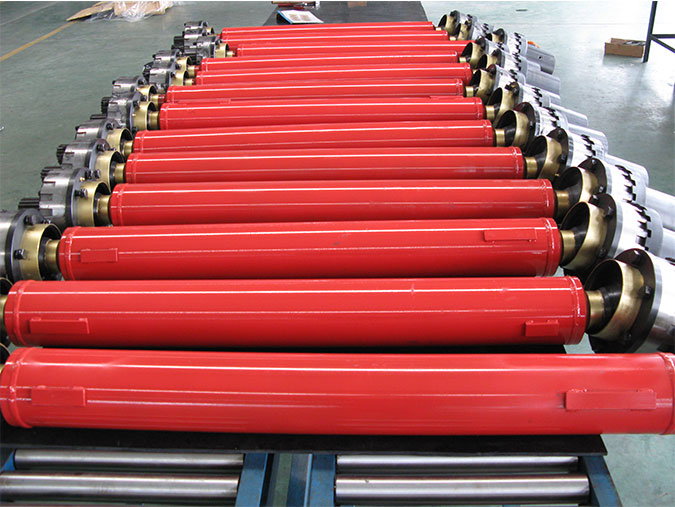

Galvanizing line tension leveler is a continuous stretching bending straightening machine that is used in the continuous hot-dip galvanizing line. Combining the characteristics of continuous tension metal straightener and roller straightener, the strip is straightened by plastic extension under the joint action of the tension roller and the bending roller. At the same time, in order to ensure the strip shape and surface quality, the tension leveler machine in tension leveling line can be equipped with wet production mode, to achieve "wet type leveler" production.

Application Scope of Tension Leveler for Galvanizing Line

Application Scope OfGalvanizing Line Tension Leveler (Dry Type)

|

Material |

Strip thickness |

Strip Width |

Yield Strength |

Leveling Speed |

|

Galvanized sheet carbon steel |

700-1800mm |

≤800MPa |

≤300m/min |

Application Scope OfGalvanizing Line Tension Leveler (Wet Type)

|

Material |

Strip thickness |

Strip Width |

Yield Strength |

Leveling Speed |

|

Galvanized sheet (Automobile, home appliance sheet) |

500-2800mm |

≤600MPa |

≤500m/min |

Structure Advantage of Tension Leveler for Galvanizing Line

Structure Advantage Of Galvanizing Line Tension Leveler (Dry Type)

The frame of the tension leveling steel is an assembly part, and each part is annealed separately to eliminate stress and ensure the frame is not deformed after long-term use. Meanwhile, it also provides convenience for later maintenance.

The roll-changing device is safe and convenient. It is driven by hydraulic pressure. One or all of the roller cassettes can be replaced at one time

The top roller system can be opened quickly to prevent the roller from being damaged. The bottom roller system is used for improving the flatness by adjusting the insertion amount of the lifter. The ball cage coupling is used to connect the driving motor, lifter and detection encoder to facilitate flexible adjustment and maintenance.

Configuring with two sets bending units and two sets leveling units can effectively improve the plate shap, C bending and L bending, according to the incoming material condition and process requirements, the two sets of bending units can also be used for one use and one standby.

Structure Advantage Of Galvanizing Line Tension Leveler (wet Type)

Configuring with two sets bending units and two sets of tension levellercan effectively improve the plate shape, C bending and L bending, according to the incoming material condition and process requirements, the two sets of bending units can also be used for one use and one standby.

The frame is an assembly part, and each part is annealed separately to eliminate stress and ensure the frame is not deformed after long-term use. At the same time, it also provides convenience for later maintenance.

The roll-changing device is safe and convenient. It is driven by hydraulic pressure. One or all of the roller cassettes can be replaced at one time

The top roller system can be opened quickly to prevent the roller from being damaged. The bottom roller system is used for improving the flatness by adjusting the insertion amount of the lifter. The ball cage coupling is used to connect the driving motor, lifter and the detection encoder to facilitate the flexible adjustment and maintenance.

The roller leveling machine can be completely out of contact with the strip when the tension leveler is not put into use to prevent scratches.

The top roller system and the inner wall of the frame have taken effective medium anti-rust measures, which can effectively prevent rust water from dripping on the surface of the strip and affecting the quality of the strip.

Spray device is equipped to clean the strip surface and roller surface to ensure the surface quality of the strip.

The main body of the tension leveler machinehas taken effective waterproof, anti-rust measures, good sprinkler and backwater system, which can ensure long-term reliable and stable operation of equipment.

What's The Function of Tension LevelerIn Galvanizing Line

The tension leveler machine is usually installed after skin pass mill in the continuous galvanizing unit. After the annealing galvanizing and skin pass process, the strip defect can be removed by the tension leveler machine to obtain good product quality.

Specifically:

- Eliminate the anisotropic of sheet, cold rolled low carbon steel in deep drawing process, the yield limit of material in transverse and longitudinal often showed obvious anisotropy, make the punched part uneven thickness in two directions, has lace skirt shape defects and not easy for deep forming. Through the proper process of tension leveler machine, sheet yield limit anisotropy is obviously improved, The deep punching performance of sheet is improved effectively.

Boya company, as an excellent tension levelermanufacturer, offers a wide range of flat rolling for you to choose from.

Send product request

Other supplier products

| Non-standard Bearing | Nonstandard bearings are bearings that do not conform to the outline dimensions stipulated by the national standards, that is, the outline dimensio... | |

| Tension Leveler Unit | BOYA Tension leveleris the core equipment to leveling and shaping strip in cold rolling mill various process lines such as pickling line/pickling a... | |

| Ball Joint Bearing for Petrochemical Industry | Ball Joint Bearingfor Petrochemical Industry BOYA's ball joint shaftare widely used in the field of electric and diesel drives for oil drilling an... | |

| Non-standard Bearing | Non-standard bearingare bearings that do not conform to the outline dimensions stipulated by the national standards, that is, the outline dimension... | |

| Fine Blanking Line | Based on BOYA's excellent processing and manufacturing capacity and rich series of products, we have a complete set of fine blanking equipment for ... |

Same products

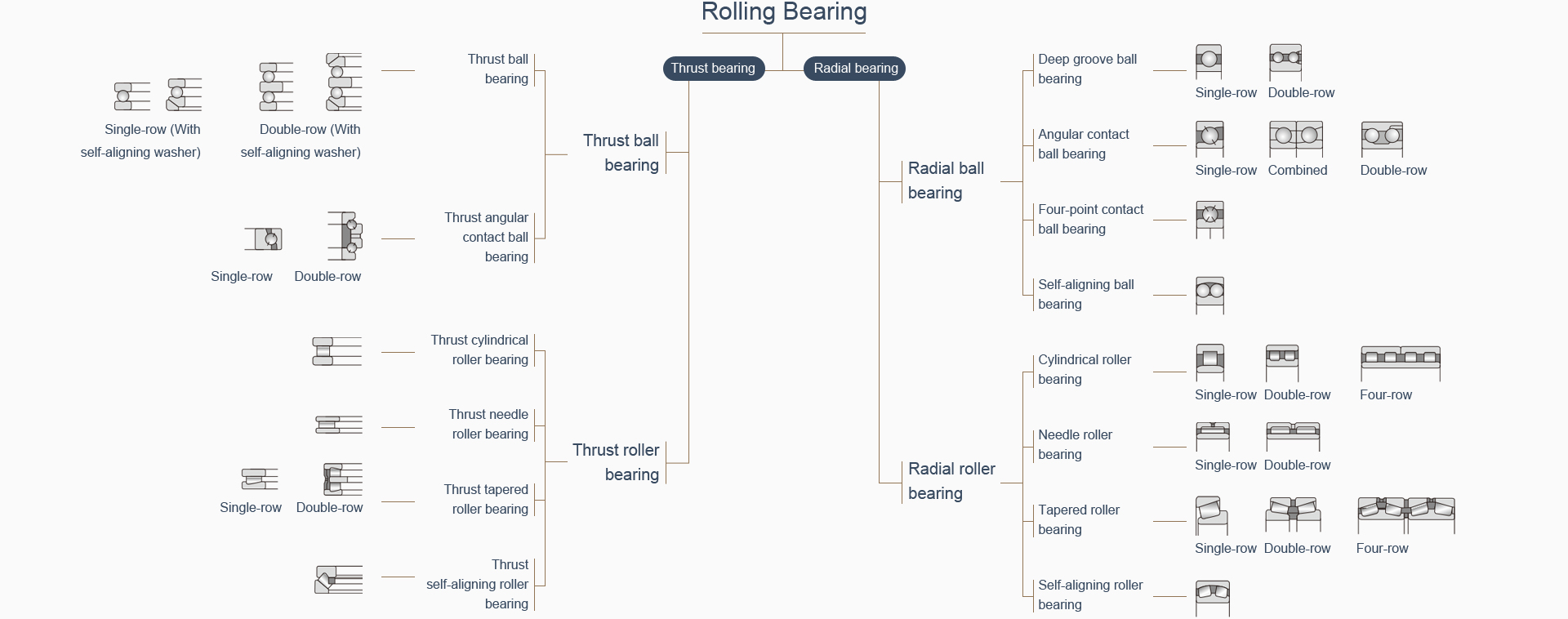

| Bearing Types And Applications | Seller: DLAIAN GUANGYANG BEARING CO., LTD | Bearing Types and Uses Types of ball and roller bearings for sale Ball Bearings Ball bearings ... | |

| Constant Velocity Joint | Seller: BOYA Precision Industrial Equipments Co.,Ltd | Constant Velocity Joint is the advantage product of BOYA, which is very welcomed by design instit... | |

| CV Joint Bearing For Steel and Non-ferrous Metal Industries | Seller: BOYA Precision Industrial Equipments Co.,Ltd | The main CV joint bearing is ball cage type, designed and developed BJ, BHJ, BJS, BC, DOJ five ca... | |

| Ball Joint Bearing for Petrochemical Industry | Seller: BOYA Precision Industrial Equipments Co.,Ltd | Ball Joint Bearingfor Petrochemical Industry BOYA's ball joint shaftare widely used in the field... | |

| Tension Leveler for Galvanizing Line | Seller: BOYA Precision Industrial Equipments Co.,Ltd | Galvanizing line tension leveler is a continuous stretching bending straightening machine that is... |