SILICON METAL FURNACE

SILICON METAL FURNACE

Industrial silicon (also called crystalline silicon, metal silicon) is one of the important materials in modern industrial production. Industrial silicon is widely used in electronics, steelmaking, optics, machinery, automobile manufacturing, chemical industry, metallurgy, medicine, national defense and other fields. At present, the application of industrial silicon is still developing new fields, such as manufacturing solar cells and silicon nitride synthetic optical fibers. Solar energy has become the most concerned green energy industry.

ADVANTAGES

ADVANTAGES OF CHNZBECH SILICON METAL FURNACE

The advantages of replacing one three-phase furnace transformer with three single-phase side outlet transformers are as follows:

The total length of secondary circuit is nearly 2/3 shorter than that of one three-phase transformer, which saves investment in secondary circuit, increases power factor and saves electricity. Three single-phase transformers are arranged 120 degrees from the main body of the furnace to each other. The load distribution is balanced and the power of three electrodes is balanced. The problems of strong and weak phases in the smelting of a three-phase transformer are solved, which creates favorable conditions for improving product quality, output and reducing power consumption.

Energy-saving current density of conductive copper tubes and water-cooled cables promulgated by the Ministry of Chemical Industry are used in the secondary circuit, with current density of 2.5-3A/ mm2 and current density of copper bushes and electrodes of 1.1-1.9A/cm2. It can run at 30% overload. The secondary circuit is safe and reliable. The implement of the above two items can increase the natural power factor of ore heat by 8-12%.

The holder adopts our company's patented products, bellows pressure rings and water-cooled protective jackets with bottom rings, which can protect the copper tile and pressure rings with water-cooled from damage caused by high temperature and ignition. It not only prolongs the service life of copper tile and pressure rings, but also greatly improves the operating rate of the holder equipment and creates reliable conditions fo hrigh yield.

Using tamping silicon arc furnaceand pusher, a batch of material is weighed accurately when proportioning, and the mixture is evenly loaded and unloaded into the middle feed bin by belt conveyor. By adding the feeder into this submerged arc furnace silicon, the feeding of silica and reducing agent is uniform, which solves the common problem of automatic feeding segregation in large and medium-sized industrial furnaces, and greatly reduces the unit power consumption.

SPECIFICATIONS

SILICON METAL FURNACE SPECIFICATIONS

|

Grade |

Type number |

Chemical Constituents |

||||

|

(code number) |

Si(>) |

Impurity content (<=) |

Total impurities (<) |

|||

|

Fe |

Al |

Ca |

||||

|

Chemical silicon |

Si—2203 |

|||||

|

Si—3303 |

99 |

1 |

||||

|

Si—3305 |

99 |

1 |

||||

|

Si—441 |

99 |

|||||

|

Metallurgical Silicon |

Si—553 |

|||||

|

Si—1 |

98 |

- |

2 |

|||

|

Si—2 |

98 |

1 |

- |

2 |

||

Annual Consumption Scale for 2*12500 Industrial Silicon Furnaces

|

Name |

Unit consumption |

Daily consumption |

Monthly consumption |

Annual consumption |

|

|

(t/t) |

(t/day) |

(t/month) |

(t) |

||

|

1 |

Silica |

4212 |

46332 |

||

|

2 |

Petroleum coke |

1092 |

12012 |

||

|

3 |

Charcoal |

468 |

5148 |

||

|

4 |

Oxygen |

130 bottles |

3900 bottles |

42900 bottles |

|

|

5 |

Water consumption |

19938 |

219318 |

||

|

6 |

Electrodes |

||||

|

7 |

Wood |

468 |

5148 |

||

|

8 |

Anthracite |

468 |

5148 |

If you want to know more details of furnace steel plant, please visit our website.

Send product request

Other supplier products

| COPPER CLADDED ELECTRODE ARM | The conductive electrode armis a new type of cross arm made of copper steel composite plate or aluminum steel composite plate, with a rectangular c... | |

| LOW CARBON FERROCHROME FURNACE | The main raw materials for smelting low-carbon ferrochromium using the electro silicothermic method include chromium ore, silicon chromium alloy, a... | |

| EAF ROOF | In the past, the EAF (electric arc furnace) roof mostly used plate type fully water-cooled furnace covers, masonry furnace covers, or plate type se... | |

| OXYGEN LANCE MANIPULATOR | The carbon-oxygen lance mainly refers to the EAF smelting, generally referring to the carbon-oxygen lance at the EAF furnace door, as well as the f... | |

| SCRAP BUCKET | In steelmaking equipment, the scrap bucketis a device for loading scrap steel, used to inject scrap steel into the steelmaking furnace. The steel b... |

Same products

| Galvanized Steel Grating for Drainage | Seller: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating for Drainage Steel gratingfor drainage, also known as galvanised draina... | |

| Floor Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Floor Grating Floor grating, also known as open grid flooringor bar grating, is a type of structu... | |

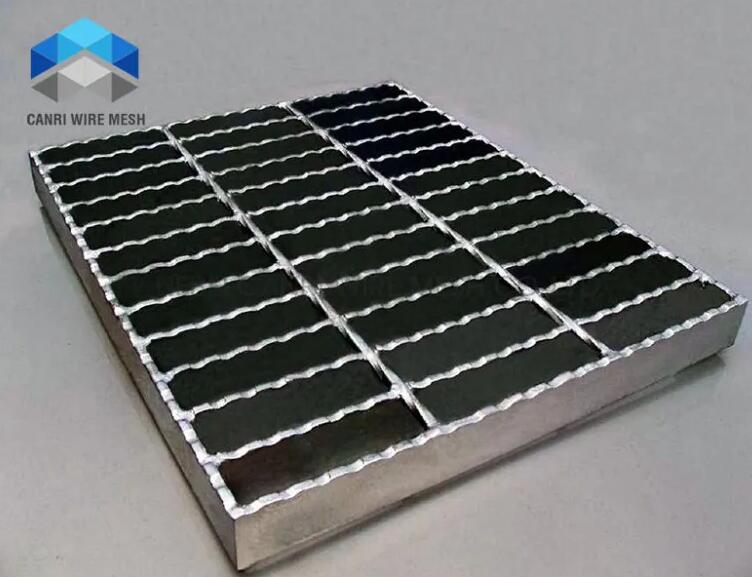

| Serrated Bar Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Serrated Bar Steel Grating Steel bar gratinghas two surface type: serrated surface and smooth su... | |

| Stainless Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Stainless Steel Grating Stainless steel gratinghas been the standard industrial foot walk produc... | |

| Galvanized Steel Grating | Seller: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating Galvanized steel gratingis an ideal product for wet, slippery situation... |