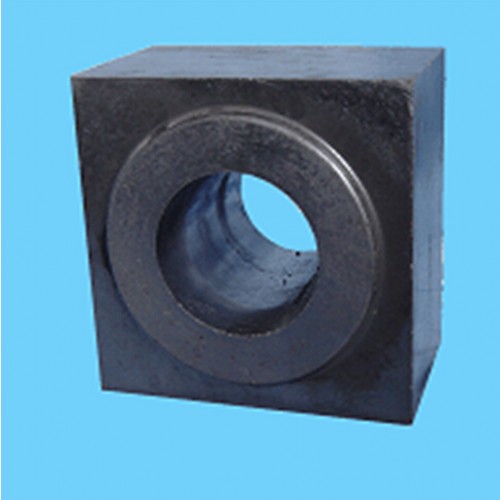

Refractory Tundish Well Llock

Refractory Tundish Well block is using together with upper nozzle,and the quality have great influence on the continuous casting ,so the quality requirement on tundish well block :

1.High erosion resistance,high thermal shock resistance.

2.Tundish well block easier to install,precision match with nozzle,high safety coefficient,low labor.

3.Lower consumption on refractories and lower the cost of steel casting.can greatly meed client requirement ,and save raw materials and improve the economic benefit.

Tundish well block feature: With high erosion resistance,work together with zirconia nozzle can keep long time no change on shape,no crack etc good feature,can better meet client requirement.

Tundish well bock were used for tundish,used together with zirconia nozzle,for continuous casting of blooms, billets ,rectangular billet and slab casting.

Other supplier products

|

|

Refractory Tundish Well Llock |

Refractory Tundish Well block is using together with upper nozzle,and the quality have great influence on the continuous casting ,so the quality re... |

|

|

Ladle Sliding Plate for Metallurgy Industry |

Material:AlC

OEM/ODM is available

We have moren than 20 years experience in producing ladle sliding plate for matellurgy industry

Quality is reliab... |

|

|

Refractory Tundish Well Llock |

Refractory Tundish Well block is using together with upper nozzle,and the quality have great influence on the continuous casting ,so the quality re... |

|

|

Tundish Nozzle |

Topchase zirconia insert Zr content94-95% andnozzlewithmetal shell,canprotectnozzle burst.thecasting temperaturenormallyat 1520-1580 ℃.

ourzirconia... |

All supplier products

Same products