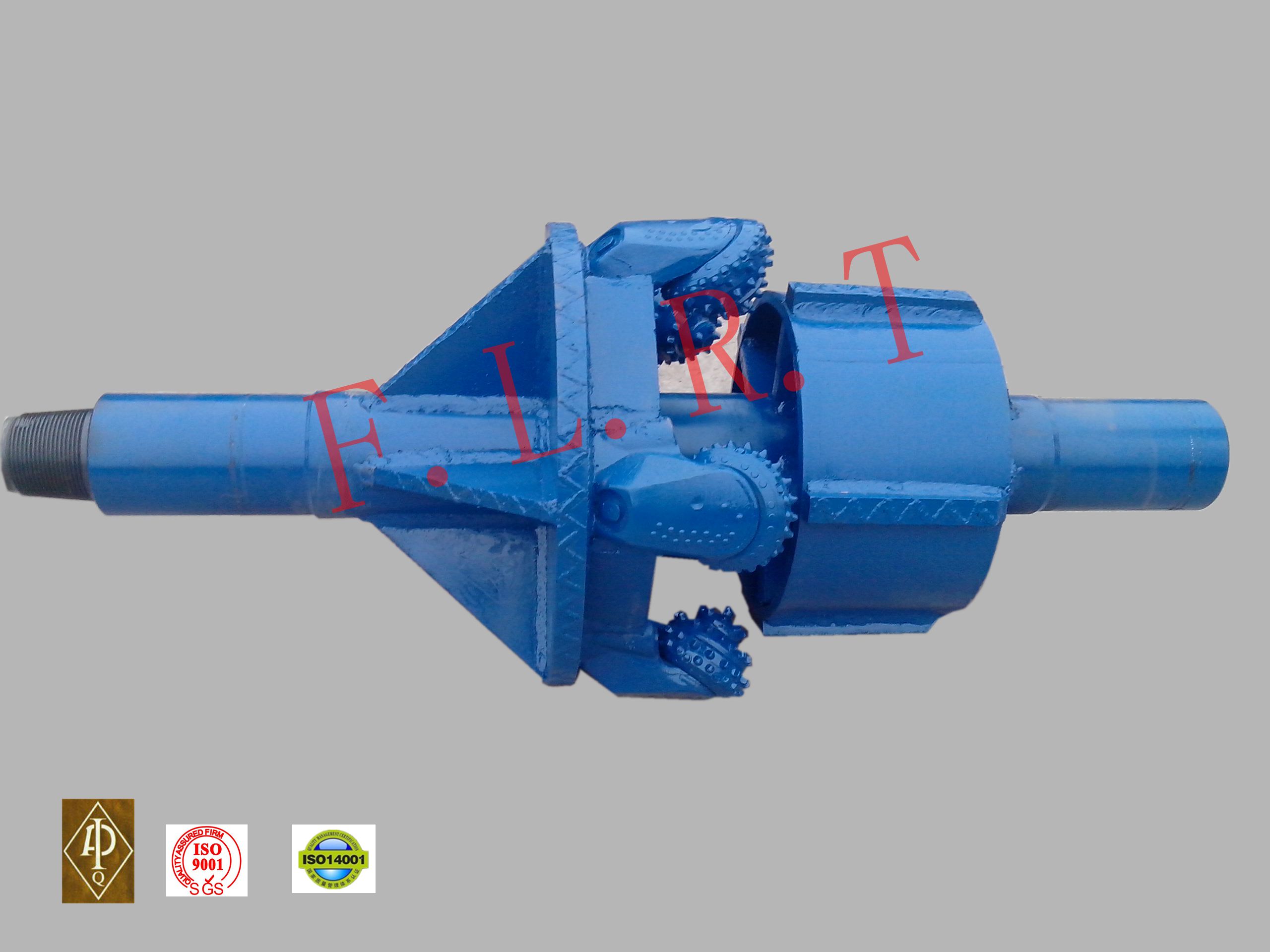

roller bit

FA series journal bearing tricone bit cutting structure

The wear-resistance of teeth is enhanced with premium tungsten carbide hardfacing on the tooth surfaces for steel tooth bit. The durability of premium tungsten carbide inserts is improved with new formulas and new techniques for insert bit.

Gauge structure

Multiple gauge protection with gauge trimmers on the heel and gauge inserts on the gauge surface of the cone, tungsten carbide inserts and hardfacing on the shirttail increase gauge holding capacity and bearing life.

Bearing structure

High precision journal with two thrust faces, balls lock the cone. Hardfaced head bearing surface. Cone bearing inlaid with friction-reducing alloy and then silver-plated. Abrasion resistance and seizure of the bearing are improved, and suitable of high rotary speed.

Seal and lubrication

Premium HNBR O-ring, optimal seal compression and curve seal structure can enhance the seal performance. The pressure compensator system and advanced grease can greatly increase the lubrication reliability.

Product application

It can receive high WOB in the conventional drilling. It is suitable for various formations by matching cutting structure with different tooth shape, tooth density and tooth exposure height.

|

Bit size |

Bit type |

|

|

In |

mm |

FA527C |

|

3 1/2 |

FA126, FA517 |

|

|

4 5/8 |

FA116C |

|

|

4 3/4 |

FA216, FA537, FA547, FA637 |

|

|

5 7/8 |

FA117W, FA216, FA246, FA517, FA547 |

|

|

6 |

FA127W, FA247, FA517, FA527, FA547, FA637 |

|

|

6 1/4 |

FA127W, FA247, FA517, FA527, FA547, FA637 |

|

|

6 1/2 |

FA127W, FA217, FA517, FA537 |

|

|

6 3/4 |

FA116GW, FA447, FA537 |

|

|

7 1/2 |

FA127W, FA217, FA517, FAT517, FA527, FAT527, FA617 |

|

|

7 7/8 |

FA117GW, FA437G, FA517G, FA527G, FA537G, FA547G, FA547GY, FA617GY, FA627G, FA637GY |

|

|

8 3/8 |

FA217, FA527, FA547 |

|

|

8 1/2 |

FAT117W, FAT127W, FA137W, FA217, FA247, FAT437GK, FAT447GK, FAT517GK, FAT527GK, FAT537G, FAT547G, FAT617G |

|

|

8 3/4 |

FA116GW, FA437GK, FAT517G, FA537G, FA627G |

|

|

9 1/2 |

FAT117GW, FAT127GW, FAT417G, FAT437G, FAT517G, FAT537, FAT547G, FAT617G |

|

|

9 5/8 |

FAT437G, FAT517G, FA527G, FA537G, FA547G, FA617G |

|

|

9 7/8 |

FA117GW, FAT417GK, FAT437G, FAT527G, FA537G, FA547G |

|

|

10 |

254 |

FA126W |

|

10 5/8 |

FAT127GW, FA217G, FAT437G, FAT517G, FAT547G |

|

|

11 |

FA117GW, FA517G, FA537G |

|

|

11 5/8 |

FA117GW, FA127GW, FA137GW, FA217G, FAT417G, FAT517G, FAT537G, FAT547G |

|

|

12 |

FA126W, FA216, FAT517, FAT537, FAT547, FA617 |

|

|

12 1/4 |

FAT117W, FA127W, FA137, FAT417GK, FAT437G, FAT517G, FAT527G, FAT537G, FAT547G, FAT617GY, FA627G, FA637G |

|

|

12 3/8 |

FAT437G, FAT517G, FAT527G, FAT537G, FAT547G, FA617GY |

|

|

12 15/32 |

FAT437G, FAT517G, FAT527G, FAT537G, FAT547G, FAT617GY, FA627G, FA637G |

|

|

13 1/8 |

FAT437G, FAT517G, FAT527G, FAT537G, FAT547G |

|

|

13 5/8 |

FA437G, FA517G, FA537G |

|

|

13 3/4 |

FA437G, FA517G, FA537G |

|

|

14 3/4 |

FA117GW, FA127GW, FA137G, FA517G, FA527G |

|

|

15 1/2 |

FA127GW, FA217G, FA517G, FA527G, FA537G, FA547G |

|

|

16 |

FAT117GW, FAT127GW, FA127GW, FA127G, FAT517G, FAT527G, FA535, FAT537G, FAT547G, FA545 |

|

|

17 1/2 |

FAT117GW, FA127W, FA137, FAT437G, FAT517G, FAT527G, FAT537G, FAT547G |

|

|

18 |

FAT547G |

|

|

18 1/2 |

FA547G |

|

Recommended drilling parameters

|

IADC |

WOB(KN/mm) (bit dia) |

RPM(r/m) |

Applicable formations |

|

116 117 |

0,35-0.8 |

150-80 |

Very soft formations with low compressive strength and high drillability. Such as clay, mudstone, chalk, etc |

|

126 127 |

150-70 |

Soft formations with low compressive strength and high drillability, such as mudstone, gypsum, salt, soft shale, soft limestone, etc |

|

|

136 137 |

120-60 |

Soft to medium soft formations with low compressive strength and high drillability, such as medium soft shale, hard gypsum, medium soft limestone, medium soft sandstone, soft formation with harder interbeds, etc |

|

|

216 217 |

100-60 |

Medium formations with high compressive strength, such as medium soft shale, hard gypsum, medium soft limestone, medium soft sandstone, soft formations with harder interbeds, etc |

|

|

246 247 |

80-50 |

Medium hard formations with high compressive strength, such as abrasive shale, limestone, sandstone, dolomite, hard gypsum, marble, etc |

|

|

417 437 447 |

150-70 |

Very soft formations with low compressive strength and high drillability, such as clay, mudstone, chalk gypsum, salt , soft shale, soft limestone, etc. |

|

|

517 527 |

140-60 |

Soft formations with low compressive strength and high drillability such as mudstone, gypsum, salt, soft shale, soft limestone, etc |

|

|

537 547 |

120-50 |

Soft to medium formations with low compressive strength, such as medium soft shale, medium soft limestone, medium soft sandstone, medium formation with harder and abrasive interbeds, etc |

|

|

617 627 |

90-50 |

Medium hard formation with high compressive strength such as hard shale, limestone, sandstone, dolomite, etc |

|

|

637 |

80-40 |

Hard formations wiyh high compressive strength, such as sandstone, limestone, dolomite, hard gypsum, marble, etc |

Send product request

Other supplier products

| hole opener | Specifications Large Diameter Reamer Bit 1. Steel tooth & TCI available 2. 6"-42" in diameter 3. Strict Quality Control System hole opener d... | |

| roller bit | FA series journal bearing tricone bit cutting structure The wear-resistance of teeth is enhanced with premium tungsten carbide hardfacing on the ... | |

| tricone bit | FJ series metal sealed bearing tricone bit Cutting structure The wear-resistance of teeth is enhanced with premium tungsten carbide hardfacing on t... | |

| tricone bit | FJ series metal sealed bearing tricone bit Cutting structure The wear-resistance of teeth is enhanced with premium tungsten carbide hardfacing on... | |

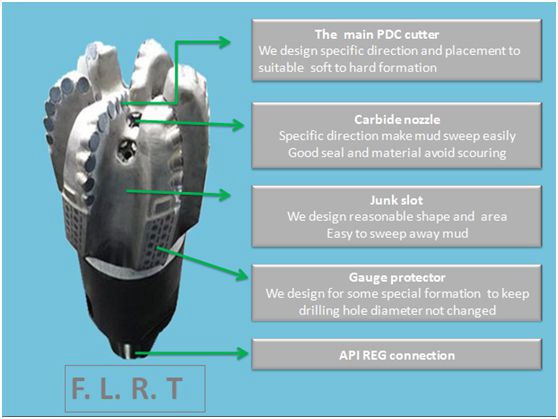

| PDC bit | 6”(5 7/8) FM1665AGU IADC: M333 Product features:Matrix PDC with six blades of parabola crown profile and with middle cutter density. With i... |

Same products

| AEMK 588 Loader | Seller: AEMK MACHINE CO.,LTD | Cab Height :2670mm Overall Dimensions ( L * W * H ):5700*2000*2670mm Front Wheel Counterweight ... | |

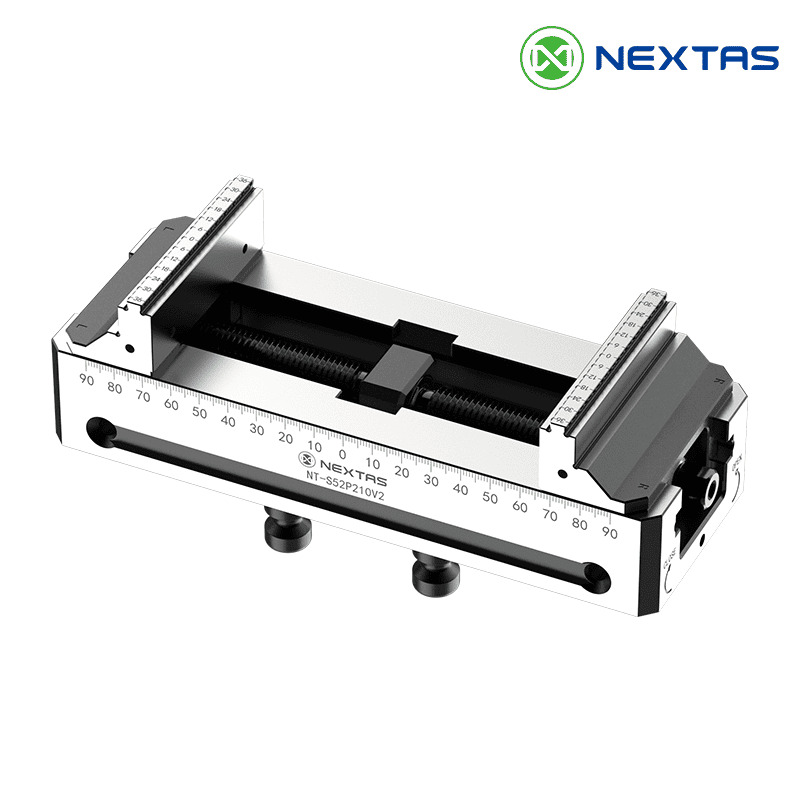

| Quick Change Worktable | Seller: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

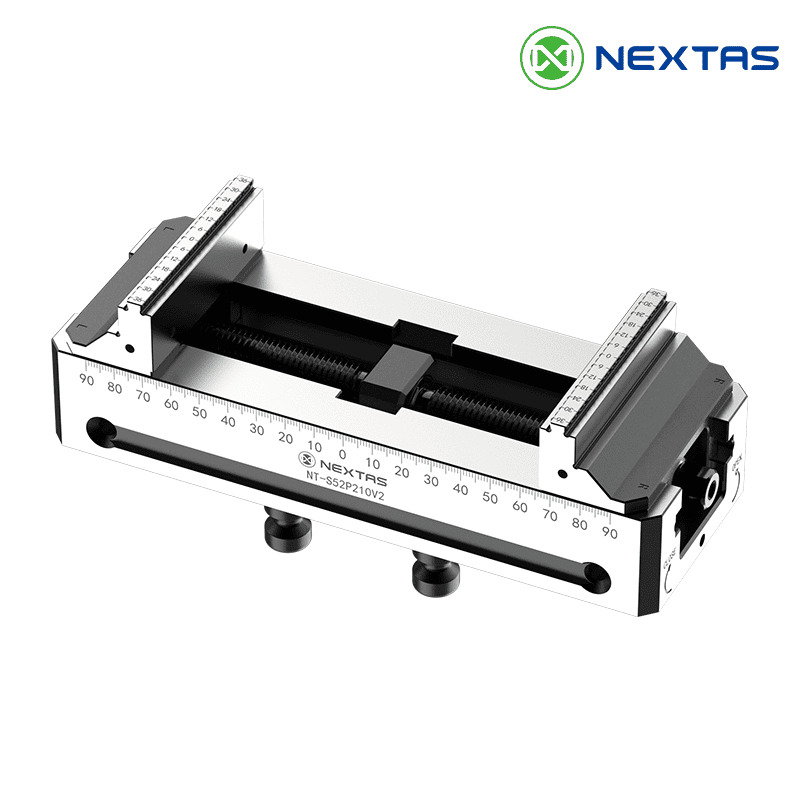

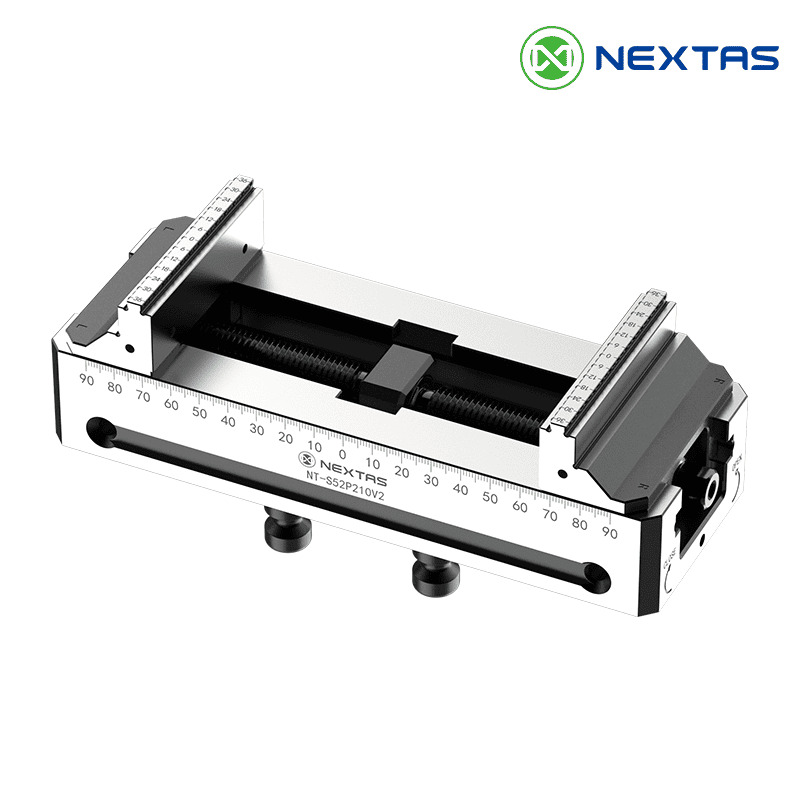

| Self Centering Vise | Seller: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | Seller: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | Seller: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |