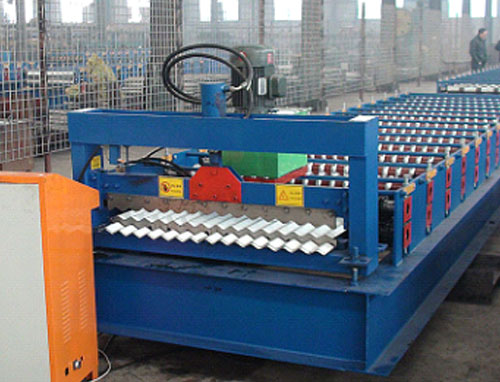

roll former machines

Bythe1990'scomputerassistedrollformermachinedesignsystemswereintroduced,andsincethattimemany

programmablecontrollersandcomputersystemshavegreatlyincreasedefficiencyandproduct

quality.Anexampleisthedoubleduplexrollformingmill,whichhasaduplexrollformerupstream

followedbyaduplexrollformerdownstreamonthesamebase.Theupstreammillcontrolsthelegorflangeheightby

glidinginandout,whilethedownstreammillcontrolsthewidthofthewebinthesamefashion.Anexampleofthistypeofrollformeristhe

Studmaker,whichrepresentsthelatestintechnologicalinnovation:changesintheheightoftheflangeorthewidthof

thewebcanbemadeinlessthantwentyminutes.SteelstudscanbeproducedinbothEnglishandmetricsizeswithout

rollorcutoffdiechanges.TheStudmakerisapre-cutoperationwhicheliminatestheneedforcutoffdiesanddiary

pairs.Materialsizesvaryingfrom12to20gauge,andstudsizesvaryingfrom3-5/8inches

to14inches,enablethemanufacturertoproducesteelframing,lightdrywallstudandload-bearing

stud,sliptrackandheavy12-gaugejoist,onthesamemachinewithminimalchangeoverdowntime.Minimizing

changeoverdowntimeisespeciallycosteffectiveforrelativelysmallorders-theStudmakercanberetooledinlessthan

twentyminutes,whereolderrollformermachinesrequireduptoeighthourssetuptimetomakethesamechange.Newroll

formingtechnologypermitssimilarproducts-suchasceeandzeeprofiles-tobeproducedonthesamesetofrolls.

Thisisdonebysplittingthemillalongitscenter,andsettingtheflange,web,andearsizesusing

acontrolpanelwhichcanmovethemillraftstochangethesizes.Itisevenpossibletochange

profilesatthetouchofabutton.Forexample,thePurlinmastercanrollformceeprofilepurlins,andcanberetooledtoroll

formzeeprofilepurlinsinonly7seconds.Besidesceeandzeeprofilepurlins,thisrollformercanalsoproducelipped

anduchannelprofiles.Webwidthandflangeheightcanbechangedinminutesinsteadofthehoursrequiredby

conventionalrollformers.ThePurlinmasteralsohasanauto-gaugingfeaturewhichpermitstheoperatortochangefrom

onecoilthicknesstoanotherwithoutretoolingatall-thenewgaugecanbeselectedimmediatelyfromtheoperator's

controlconsole.ThePurlinmastercanproduceprepaintedpurlinaswellasgalvanizedandhotrolledblacksteel,atspeedsupto180fpmand

withawidevarietyofholepunchingoptionsforinlineflangeandwebholepunchingofthehighestaccuracy.Whenyouarereadyforthelatestin

containerpanelformingmachinetechnology,letSamco'sexpertstaffhelpyouplanandselecttheidealmachineryforyourneeds.OurStudmaker

andPurlinmasterareonthecuttingedgeofrollforminghistory.

Send product request

Other supplier products

| light keel roll forming machine 1 | light keel roll forming machineProducts made bylight keel roll forming machineis easy to install. Width of 75, 100, 150 C-shaped keel can be assemb... | |

| XN24-210-840 roll forming machine roof plate | HebeiXinnuo24-210-840roofpanelformingmachine,thefeedingwidthis1000mm, adoptingrollformingmethod,canproducebeautifulappearance, strongpanelswhicha... | |

| roll forming machine 1 | Colored steel sheet roofing sheetroll forming machineThe sheets produced by this kind of machine are widely used in all kinds of factories,houses, ... | |

| Hebei Xinnuo 8.2-130-910 roof panel forming machine | HebeiXinnuo8.2-130-910roofpanelformingmachine,thefeedingwidthis1000mm,theproductioncanbeusedforthewall.Itiswidelyusedinindustrialandcivilbuildings,... | |

| Why Need Roll Forming Machine | manypeoplemakeuseofcolorsteeltilesonthebuildings.However,notallpeopleknowhowthesecolorsteeltilesandglazedtilesandsoonaremanufactured.Asamatteroffa... |

Same products

| AEMK 588 Loader | Seller: AEMK MACHINE CO.,LTD | Cab Height :2670mm Overall Dimensions ( L * W * H ):5700*2000*2670mm Front Wheel Counterweight ... | |

| Quick Change Worktable | Seller: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

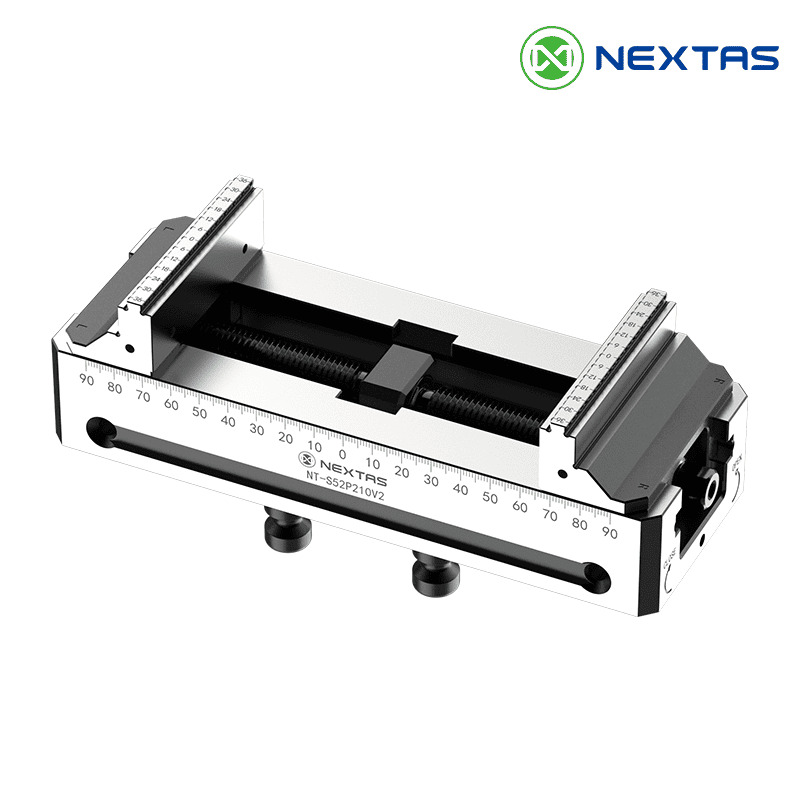

| Self Centering Vise | Seller: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | Seller: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | Seller: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |