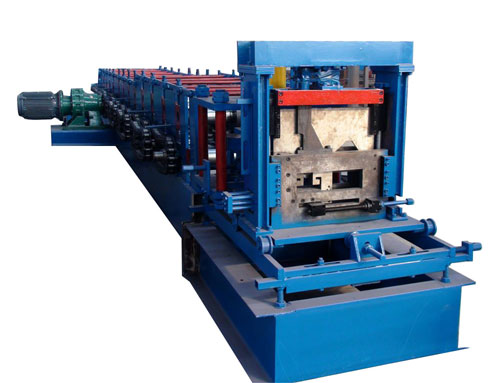

roll former machines

Bythe1990'scomputerassistedrollformermachinedesignsystemswereintroduced,andsincethattimemany

programmablecontrollersandcomputersystemshavegreatlyincreasedefficiencyandproduct

quality.Anexampleisthedoubleduplexrollformingmill,whichhasaduplexrollformerupstream

followedbyaduplexrollformerdownstreamonthesamebase.Theupstreammillcontrolsthelegorflangeheightby

glidinginandout,whilethedownstreammillcontrolsthewidthofthewebinthesamefashion.Anexampleofthistypeofrollformeristhe

Studmaker,whichrepresentsthelatestintechnologicalinnovation:changesintheheightoftheflangeorthewidthof

thewebcanbemadeinlessthantwentyminutes.SteelstudscanbeproducedinbothEnglishandmetricsizeswithout

rollorcutoffdiechanges.TheStudmakerisapre-cutoperationwhicheliminatestheneedforcutoffdiesanddiary

pairs.Materialsizesvaryingfrom12to20gauge,andstudsizesvaryingfrom3-5/8inches

to14inches,enablethemanufacturertoproducesteelframing,lightdrywallstudandload-bearing

stud,sliptrackandheavy12-gaugejoist,onthesamemachinewithminimalchangeoverdowntime.Minimizing

changeoverdowntimeisespeciallycosteffectiveforrelativelysmallorders-theStudmakercanberetooledinlessthan

twentyminutes,whereolderrollformermachinesrequireduptoeighthourssetuptimetomakethesamechange.Newroll

formingtechnologypermitssimilarproducts-suchasceeandzeeprofiles-tobeproducedonthesamesetofrolls.

Thisisdonebysplittingthemillalongitscenter,andsettingtheflange,web,andearsizesusing

acontrolpanelwhichcanmovethemillraftstochangethesizes.Itisevenpossibletochange

profilesatthetouchofabutton.Forexample,thePurlinmastercanrollformceeprofilepurlins,andcanberetooledtoroll

formzeeprofilepurlinsinonly7seconds.Besidesceeandzeeprofilepurlins,thisrollformercanalsoproducelipped

anduchannelprofiles.Webwidthandflangeheightcanbechangedinminutesinsteadofthehoursrequiredby

conventionalrollformers.ThePurlinmasteralsohasanauto-gaugingfeaturewhichpermitstheoperatortochangefrom

onecoilthicknesstoanotherwithoutretoolingatall-thenewgaugecanbeselectedimmediatelyfromtheoperator's

controlconsole.ThePurlinmastercanproduceprepaintedpurlinaswellasgalvanizedandhotrolledblacksteel,atspeedsupto180fpmand

withawidevarietyofholepunchingoptionsforinlineflangeandwebholepunchingofthehighestaccuracy.Whenyouarereadyforthelatestin

containerpanelformingmachinetechnology,letSamco'sexpertstaffhelpyouplanandselecttheidealmachineryforyourneeds.OurStudmaker

andPurlinmasterareonthecuttingedgeofrollforminghistory.

在线联系供应商

Other supplier products

| How should we are buying roll forming machines | Nowmoreandmorepeoplehavebeensellingrollformingmachine.Soinpurchasingyourownmachines,youmustconsiderthefollowingfactors: Species:YouneedSpecies... | |

| XN51-240-720 floor deck roll forming machine | bythismachineisusedforbuildingsurfacepanels,ithasmanyadvantages,suchashighwave,highstrength,highautomationandlowcost.Steelstructuralfloorpanelisth... | |

| floor deck roll forming machine 1 | floor deck roll forming machineneeds focused mainly concentrated in large, heavy, high-end products. Although the 2007 increase of gold and gold cu... | |

| XN25-144.3-1010 roof plate forming machine | HebeiXinnuo25-144.3-1010roofpanelformingmachine,thefeedingwidthis1200mm,itisthenewtypewedesign.Itiswidelyusedinindustrialandcivilbuildings,suchasw... | |

| c purlin machine | What'siscpurlinmachine? Cpurlinmachine,alsonamedcpurlinrollformer,amachinetoformcsteelpurlinsinanautomaticwaybyrollers,thismachinecomponentsinclude... |

Same products

| AEMK 588 Loader | 卖方: 烟台欣祥国际贸易有限公司 | 驾驶室高度:2670毫米 整车尺寸(长*宽*高):5700*2000*2670毫米 前轮配重:4250毫米 轴距:2500毫米 离地间隙:480毫米 最大卸料高度:3500毫米 最大... | |

| Quick Change Worktable | 卖方: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

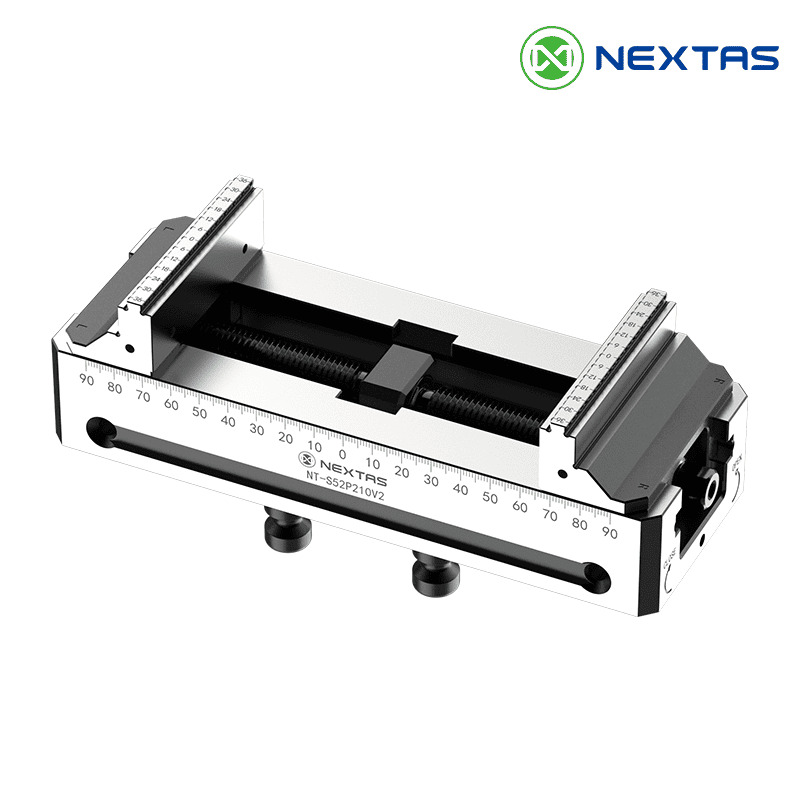

| Self Centering Vise | 卖方: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | 卖方: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | 卖方: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |