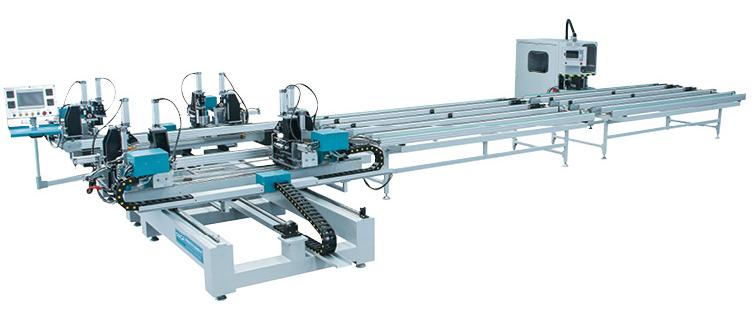

Automatic Welding/Cleaning Production Line for PVC Window and door, SHQXJ01

Processing Performance and Feature:

The production line is consist of Horizontal four corners welding machine, Conveying worktable and CNC corner cleaning machine.

it is automatic complete the whole processing for rectangular frame or sash welding, transportation frame to achieve corner cleaning process.

Welding unit adopt horizontal lay and adopt the strengthened rigidity design, firm and stable; Welding size can achieve error compensation function, high welding precision.

Corner cleaning unit is equipped with servo drive system, automatic finish cleaning for all the welding seam on the PVC window and door.

Technical parameter:

Input power source 380V/50Hz Total power 15Kw

Working air pressure 0.6-0.8Mpa Air consumption 200L/min

Welding profile height 25-180mm Welding profile width 0-120mm

Welding frame size

(length×width) 500×650-1800×3000mm Dimension

(length×width×height) 12500×5500×2200mm

Weight 4500kg

Other supplier products

All supplier products

Same products