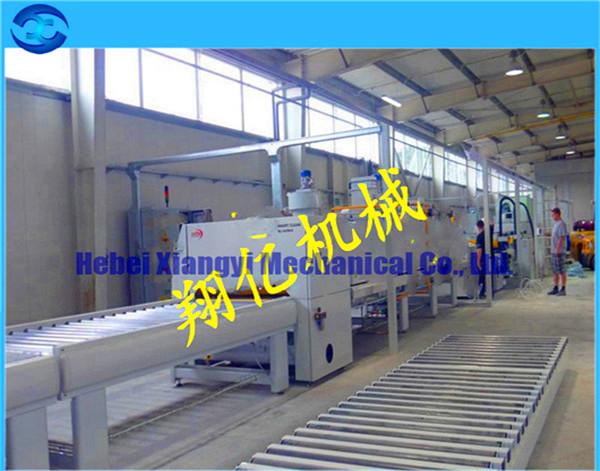

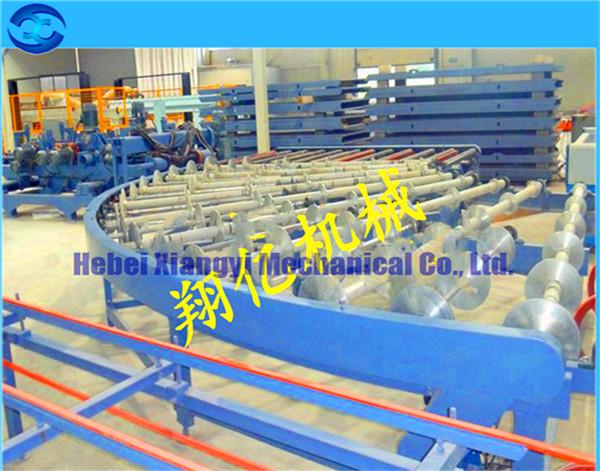

Calcium silicate board plant

Calcium silicate board plant

technoloty:

calcium silicate board use inorganic mineral fiber or cellulosic fiber as reinforcement agent and siliceos material and calcareous material as main cementitious meterial.

Process stages include: slurry preparation, board forming, stacking, pre-curing, module stripping, autoclaving and curing.

To increase board quality, drying stage as well as sanding, edging and painting stages can be assed, which also increased additional value of board.

Annual output : 200,0000 sq.m—800,0000sq.m

Chief introduction and usage:

This production line is used to making calcium silicate board continuously with

high technology and high automatic degree.

At present, no asbestos calcium silicate board (including temperature asbestos

calcium silicate board) is still in production and sales of emerging exuberant sell

well, not only in China, but also in abroad.

The basic reason is: this plank raw material origin is widespread, the price is low,

advanced production technology, equipment availability is high, the product is very

superior performance, especially energy saving, seismic, fire prevention, high

strength, light, very suitable for various kinds of building the internal and external

wall panels, sound insulation board, the ceiling and all kinds of adornment with board,

and construction is convenient, and construction speed is quick, accord with national

energy saving, environmental protection, economy applicable principle.

products Specifications:

Calcium silicate board production lineLength:1200-1220mm

Width:2400-2440mm

Thickness:4-25mm

Raw material:

Reinforced fiber- pulp, wollastonite, glass fiber, mica, chrysotile, etc.

Siliceous material -quartz powder, fly ash, diatomite etc.

Calcareous material - unslaked lime powder, cement)

We are china famous brand of manufacturering building material equipment line , has gain manyhonors , recived good reputation form government and customers in the world , except our cooperation !

As for the technical problem ,we will send the engineers to your factory to guide and train your members.

if there needs, our engineer can work for you for several weeks so that you can grasp all the technology

of operating the production line and dealing with the relative problems

Our promise and service

(1). Guarantee: All machineries for 2 years.

(2). According to your plant design, we design the layout for machinery.

(3). All machineries arrive at your factory, we will send engineers to install the machinery.

(4). engineers will guide all machineries operation.

(5). engineers will guide the panels installation

Send product request

Other supplier products

| gypsum board manufacturing machine company | gypsum board manufacturing machine company Finished gypsum boardSpecification Dimension of gypsum board: Thickness: 7mm-22mmwidth: 1200mm or 122... | |

| gypsum powder production plant | Hebeixiangyi mechanical Manufacturing Co.,Ltd ,had been 15 years experience in designing and manufacturining various of industrial machineries.... | |

| fiber cement board plant | Features of fiber cement board: one month, the phenomenon of swelling and out of shape will Not happen. It will Not disintegrate when Immer... | |

| fiber cement board machinery | Automatic Fiber Cement Board production line Capacity 2~8 million SQM Calcium silicate board per year Machine supply&installation ISO 900... | |

| Calcium silicate board plant | Calcium silicate board plant technoloty: calcium silicate board use inorganic mineral fiber or cellulosic fiber as reinforcement agent and silice... |

Same products

| AEMK 588 Loader | Seller: AEMK MACHINE CO.,LTD | Cab Height :2670mm Overall Dimensions ( L * W * H ):5700*2000*2670mm Front Wheel Counterweight ... | |

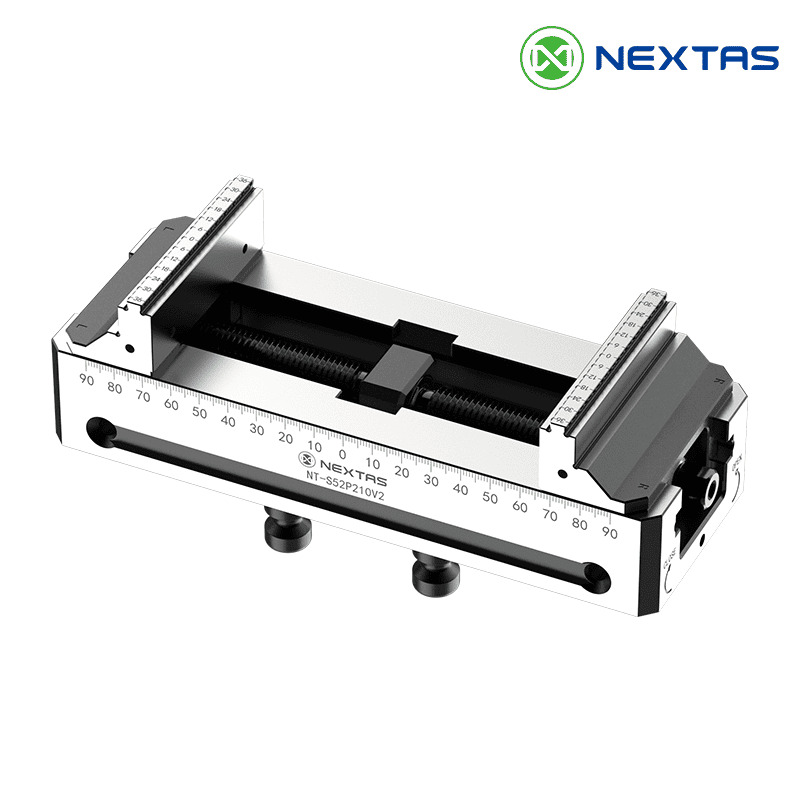

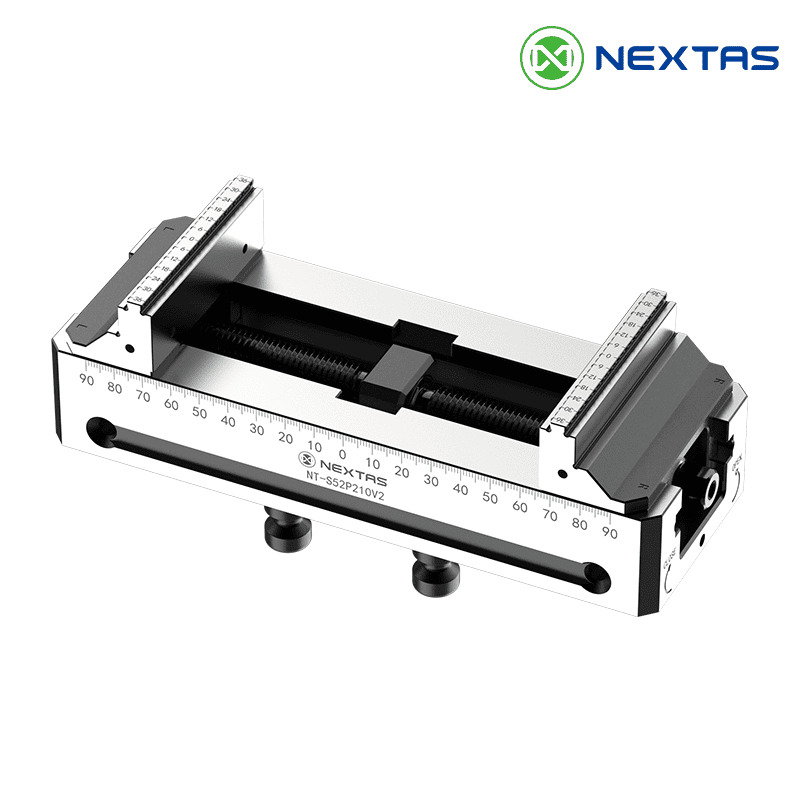

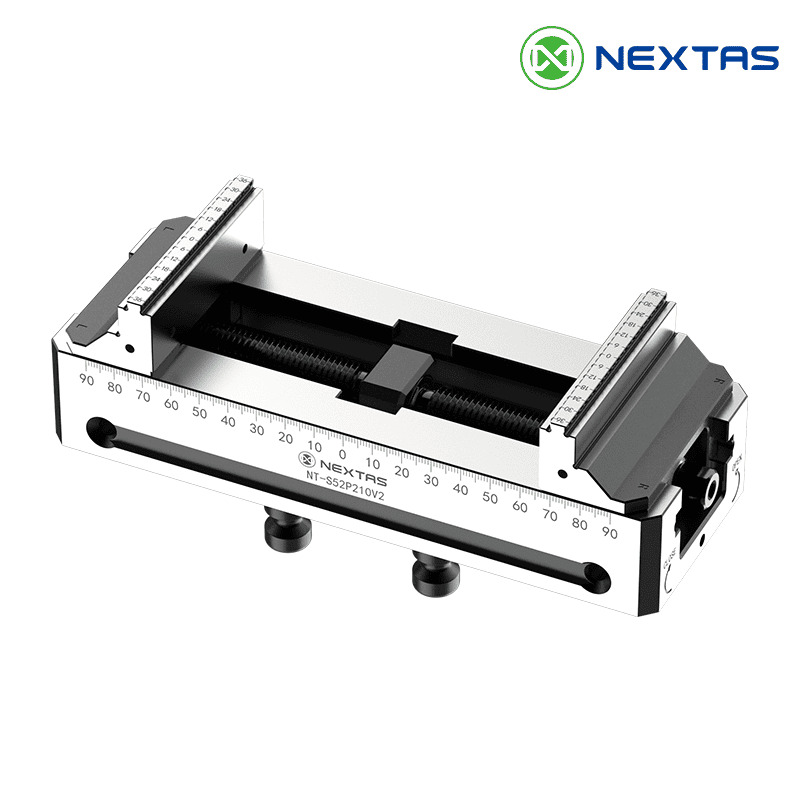

| Quick Change Worktable | Seller: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

| Self Centering Vise | Seller: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | Seller: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | Seller: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |