GALVANIZED STEEL SILO UPRIGHT DOUBLE LAYER ROLL FORMING MACHINEE

The development of

steel silo roll forming machine

and steel silo has a history of more than 100 years, from riveting warehouse, welding warehouse, assembly warehouse, to the technical warehouse of the WDCPO steel warehouse patent group technology, steel warehouse The development of the company has been more than 100 years old and has been widely used abroad.

The steel silo for grain storage originated in the early 20th century. In the late 1970s, in the foreign grain industry, the steel silo almost replaced any type of granary. At present, 95% of granaries in the United States use steel silos.

China's steel silo technology started late in the application and development of the grain industry. In 1982, Honghe Farm of Heilongjiang Province introduced galvanized corrugated sheet-mounted steel silos from the United States, which was the earliest modern steel silo group in China. In the 1990s, the construction of China's steel silos achieved unprecedented development. In the 21st century, Zhengchang introduced a complete set of technology and special equipment production lines for assembled steel silos in the United States. Based on foreign advanced technology, design software and production standards, it has innovated and developed on the basis of digestion and absorption, and started mass production.

The production and installation of the assembled steel silo makes the steel silo reliable in terms of strength, performance and safety, and exports the steel silo as a product. It represents the international level of production, production and installation of steel silos in China today. The leader of the production and installation of steel silos.

At present, steel silos can store granular, powder, grain, oil, food, brewing, coal, building materials, etc., and are widely used in industrial and agricultural fields, urban and rural areas and environmental protection industries.

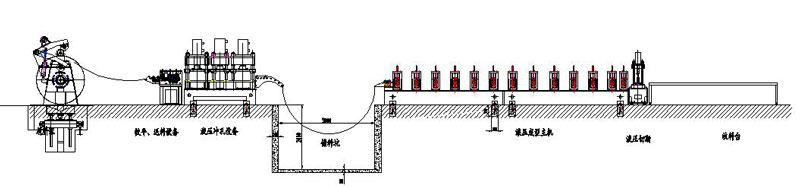

Steel silo profile production equipment performance:

Can be rolled according to the production needs of a variety of steel strip width 100mm ≤ § ≤ 1100mm steel granary.

Production speed when punching online: 5~6 m/min.

Steel sheet forming equipment continuous forming speed: 8 ~ 12 m / min.

The cold-bending forming equipment produced by our company has the following advantages:

The equipment control is PLC control, and multiple safety protection is set during normal production.

The bed is welded with steel plates. It is also tempered to eliminate internal stress and avoid deformation of the fuselage.

The forming frame is cast iron structure and tempered. High strength and long service life.

The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment.

The material of the forming mold is GCr15, quenching treatment, hardness: HRC 56-62 °C.

The transmission structure is gearbox transmission. Each molding frame has a gearbox that guarantees time-out, high-intensity operation and long service life.

Production Process

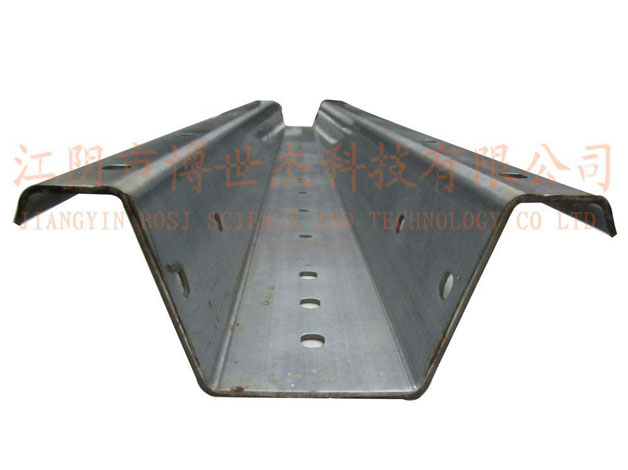

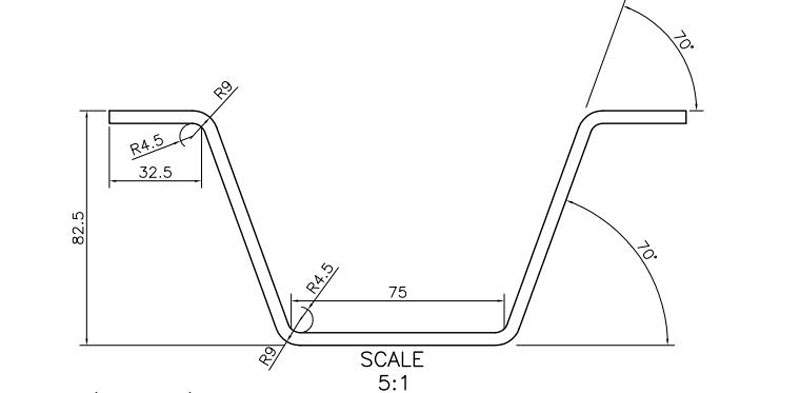

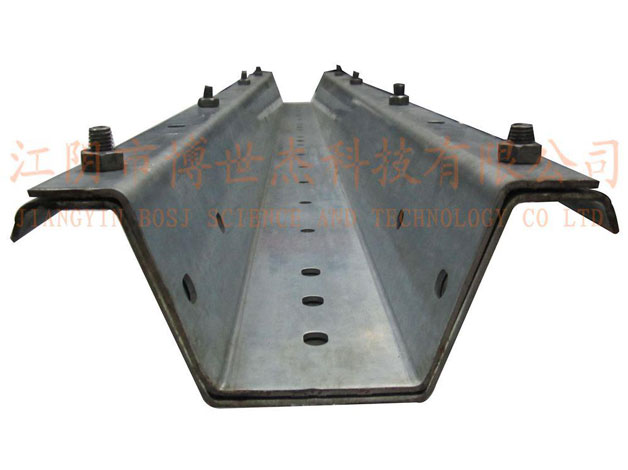

Profile drawings

BOSJ estabilished in 2004, As a leading producer of many types of

china roll forming machine manufacturer

, BOSJ has won worldwide reputation in this field. Our products have broad markets in Southeast Asia, India, North and South America,Western Asia, Russia and Australia. We guarantee first-rate after-sale service and product quality. Establishing abiding friendship with any customers interested in roll forming machines is our goal. Sincerely, we invite you to pay a visit to our company.

Send product request

Other supplier products

| STANDING SEAM ROLL FORMING MACHINE | With the gradual increase of cold rolling capacity, the consumption of rolls (including work rolls, support rolls and intermediate rolls, etc.) and... | |

| CEILING ROLL FORMING MACHINE | CEILING ROLL FORMING MACHINE Ceiling channel roll forming machine is a special machine designed for the ceiling industry. It has high speed and hi... | |

| Guardrail Roll Forming Machine | BOSJ estabilished in 2004, As one of theleading roll forming machine manufacturers in china,BOSJ has won worldwide reputation in this field. Our pr... | |

| STANDING SEAM ROLL FORMING MACHINE | With the gradual increase of cold rolling capacity, the consumption of rolls (including work rolls, support rolls and intermediate rolls, etc.) and... | |

| CABLE TRAY ROLL FORMING MACHINE | Cable tray punching machineare becoming more and more widely used in modern buildings. Traditional manual production can no longer meet the demand,... |

Same products

| Cable Pulling Sock | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Pulling Sock CABLE PULLING SOCK: The is the most ideal tool designed for electrical a... | |

| Side Dragging Cable Grip | Seller: Hebei Long Zhuo Trade Co., Ltd | Side Dragging Cable Grip Side Dragging Cable Grip SGA/MGT/SK/MK is also called cable sock w... | |

| Cable Pulling Grips TG MG TGM TGK | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Pulling Grips TG MG TGM TGK Head Traction Cable Grip TG/MG/TGM/TGK Cable grips are a ... | |

| Cable Grip Supplier | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Grip Supplier Cable Grip: A Reliable Solution for Safe Cable Pulling and Handling A... | |

| Cable Roller Manufacturer | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Roller Manufacturer Cable Roller: Essential Equipment for Safe and Efficient Cable Ins... |