CABLE TRAY ROLL FORMING MACHINE

Cable tray punching machineare becoming more and more widely used in modern buildings. Traditional manual production can no longer meet the demand, and the industry urgently needs the input of automated production lines to increase production/reduction of artificially improved product quality and reduce labor intensity.

The new cable tray automatic forming equipment developed and produced by our company is a non-standard custom equipment. According to the different requirements put forward by customers, the process design and customized production meet the requirements of speed, intelligence and equipment floor space required by customers. Tailored to the actual situation of each customer.

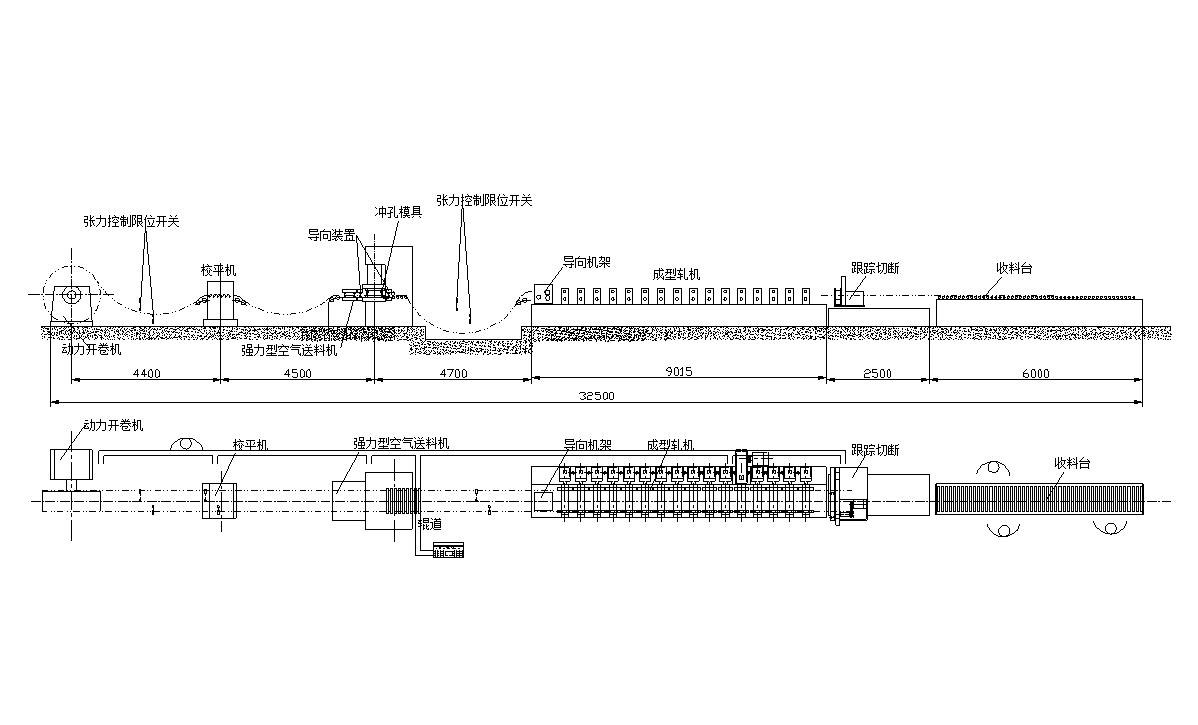

Cable Tray Machine Overview:

The cable tray equipment production line can produce cable trays. Different specifications are completed by replacing the die. The roll bending machine adopts a combination of adjustable and one set of rolls to complete all specifications of the bridge products. The specification changes are completed by adjusting the forming machine opening and rolling.

The production line is divided into automatic and manual operation modes, which can realize linkage and segmentation operation.

The complete set of equipment consists of uncoiler, leveler, servo feeder, punch, die, guide frame, forming machine, cut-off, receiving table and electrical control.

The cable tray automatic forming machine can produce 0-10m per minute, the specifications can be adjusted freely, the operation is simple and easy to learn, the production efficiency is greatly improved, and the automation degree of the enterprise is improved.

Cable tray equipment has several advantages:

The equipment control is PLC control, and multiple safety protection is set during normal production.

The bed is welded with steel plates. It is also tempered to eliminate internal stress and avoid deformation of the fuselage.

The forming frame is cast iron structure and tempered. High strength and long service life.

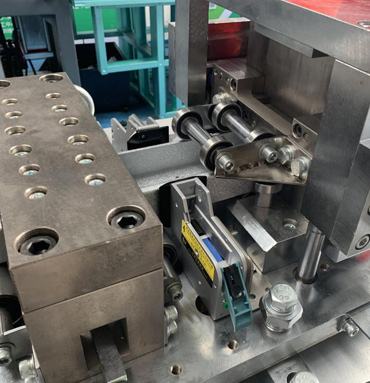

The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment.

The material of the molding die is GCr15, quenching treatment, hardness: HRC 56-62 °C.

The transmission structure is gearbox transmission. Each molding frame has a gearbox that guarantees time-out, high-intensity operation and long service life.

BOSJestablished in 2004, As a leading producer of many types of roll forming machines in China, BOSJ has won a worldwide reputation in this field. Our roll forming machine chinahave broad markets in Southeast Asia, India, North and South America, Western Asia, Russia, and Australia.

Send product request

Other supplier products

| CABLE TRAY ROLL FORMING MACHINE | Cable trays are becoming more and more widely used in modern buildings. Traditional manual production can no longer meet the demand, and the indust... | |

| Fire Control Cabinet End Cap Roll Forming Machine | Structure Of Equipment It's combined with leveler,servo-feeder/punching, roll forming, cutting and other technology The equipment-roll forming equ... | |

| CABLE TRAY ROLL FORMING MACHINE | Cable trays are becoming more and more widely used in modern buildings. Traditional manual production can no longer meet the demand, and the indust... | |

| C & U CHANNEL UNISTRUCT METAL ROLL FORMING MACHINEE | Slip Roll Former Width of material sheet:≤200 mm Thickness of material sheet: 2.0~2.5 mm Power: 380V, 50Hz, 3 phase Forming Speed with punchi... | |

| ROLLING SHUTTER SLATS ROLL FORMING MACHINE | How to select Rolling Shutter Slats Roll Forming Machine l In the selection of materials should consider more lightweight, durable materials, so th... |

Same products

| Custom Motor Mold | Seller: 846123 | 90 Three-row High-Speed Progressive Stamping Mould Custom MotorMold () The 90 Three-row High... | |

| Emergency Snow Chains | Seller: Zhejiang Pujiang Bohu Chain Stock Co., Ltd. | Our Emergency Snow Chains are engineered to deliver unbeatable grip on snow and ice, ensuring t... | |

| Universal Union with Filter Angle Valve | Seller: Zhejiang Huaqi Information Technology Co., LTD | In commercial applications, such as in hotels or office buildings, brass fill valves are used to ... | |

| Propane Gas Fire Pit Valve Control System Kit | Seller: Dong Guan ABYDA Gas Valve Co., Ltd | Product Specification:1. 1/2" Brass Control Key valve with 3/8" male flare adapter of 2;2. 3" Key... | |

| UB6 Sleeved Plug Valve | Seller: China JSC Valve Manufacturer Group Co., Ltd. | PTFE Sleeved Plug ValveValve description: Sleevedplug valve, PTFE seatDesign standard: API 599Bod... |