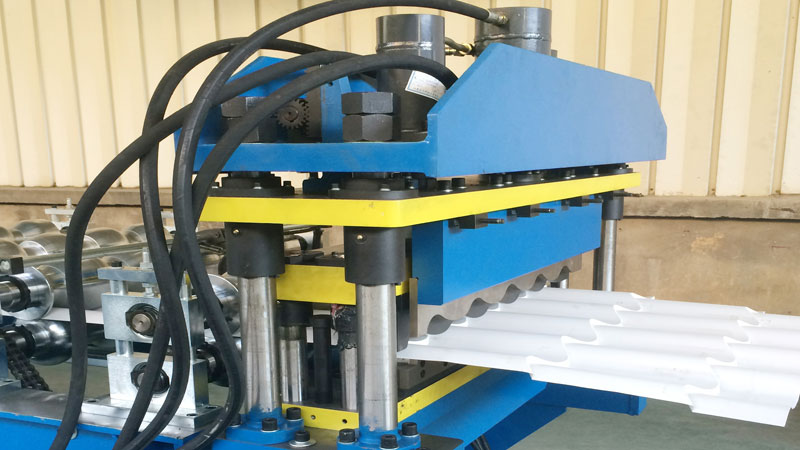

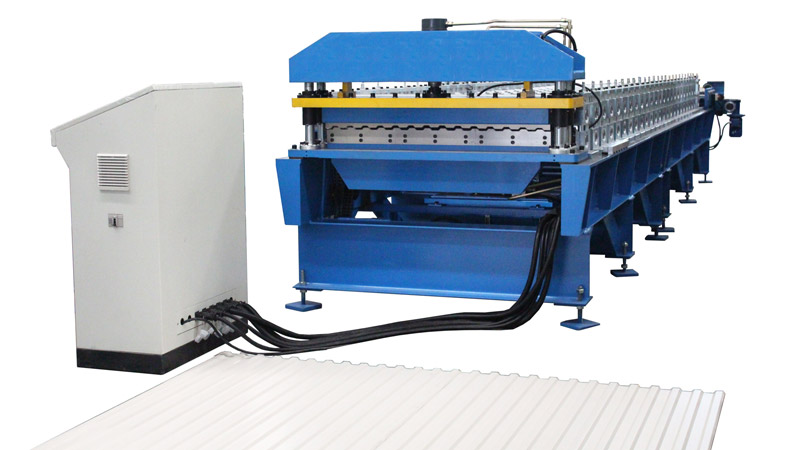

HIGH SPEED ROOFING TILE MAKING MACHINE

The high-speed metal roof tile machineis for continuously roll forming and pressing step tiles sheets. The step length of this series can be set up and the depth of each step is adjustable. Its production speed of this series is about 8-10 m/min. Similar to other wall sheet roll forming machines, this high-speed roof tile roll formeris also certified with multiple patents. In addition, prompt delivery is also available.

As a roof tile making machine factory, we specialize in the production of high-quality tile machine for sale that are designed to meet the needs of both commercial and residential customers. Our wholesale roof tile production machinesis easy to use, offer excellent performance, and is highly durable. Our tile roof machineis also designed to provide maximum strength and is equipped with state-of-the-art safety features. As one of the leading roof tile machine manufacturers, we pride ourselves on providing our customers with the highest quality products and services available in the industry.

Raw Materials for roof tile rolling machine

Material type: Color coated Steel, Aluminum sheet

Thickness: 0.4-0.6(mm)

Yield Strength: 230-350 MPa optional

Width: 1200/1220/1250(mm)

Production Line Components and Parameters of Roof Tile Machine

|

5t/8t/10t/15t Motor/hydraulic motor/passive (optional) |

|

|

optional |

|

|

optional |

|

|

no need |

|

|

individual standing column structure |

|

|

optional |

|

|

Step length, depth, head & end length is adjustable |

|

|

hydraulic |

|

|

Manual supporter/ Automatic Stacker (optional) |

|

|

Stackmaster |

(Output direction) Lateral/Longitudinal (optional) |

|

Power supply for decoiler /post-cutting system |

|

|

MITSUBISH/ SIEMENSE/AMS (optional or as requested) |

Step Roof Tile Line Layout

Working Flow of High-Speed Roofing Tile Making Machine

The working flow of our roof tiling equipment for sale usually goes as follows: Coil Charging Car (optional) - Decoiler (passive/auto) - Front Shear(optional) - Feeding and Guiding Table - Filming Covering (optional) - Roll Forming System

Advantages Of Tile Roof

A metal roof tile making machineis a type of machine used to produce roofing tiles. Tile making machinery is typically composed of a series of rollers, conveyor belts, and other components. The tile making machinery can be used to create a variety of designs and textures for roofing tiles. The corrugated roof tile making machineis often computer-controlled, allowing for precise control of the production process, but manual roof tile making machine also exists. It is a vital tool for any roofing company, as it helps ensure that the roofing tiles produced are of the highest quality. Besides roofing tile machine, glazed tile making machine is also a kind of common tile manufacturing equipment. Metal Roofing tiles perform the elegant style of traditional roof tile and suit every architectural design. What's more, it is much more convenient and takes a shorter time for installation.

Roofing Tile Drawings

Finished Roofing Tiles by High-Speed Roof Tiling Equipment

Specifications of Roof Tile Machine for Sale

|

Machine Condition |

Fully New,A Grade quality |

|

Panel Shape |

As profile drawing and customer’s requirements |

|

Operator needed |

1-2 persons |

|

Power Supply |

220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 15t |

|

Dimension (L*W*H) |

about 25*3*2m |

|

LOADING SIZE |

Normally need 1x 40' (+ 1x 20GP) container. |

|

Equipment Color |

Normally Blue/White, or as requests; |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

For more informationabout roof tile forming machine priceand direct forming technology, please feel free to contact us!

If you are looking for a reliable tube mill supplier, don't hesitate to contact us!

Send product request

Other supplier products

| Roof Panel Roll Forming Machine | This metal cladding roll forming machineis used to roll-form metal roof panels and metal wall panels. The roll forming lineusually includes metal d... | |

| Heavy Duty Shelf Column Roll Forming Machine | Features and Advantages of Heavy Duty Shelf Column Roll Forming Machine Cassette type platform quick-change Machine base for multi-profile purpose... | |

| High Frequency ERW Pipe Mill Line | High frequency welded pipe mill Line is mainly used for making ERW welded steel pipes. ERW is short for Electric Resistance Welding. At present, ER... | |

| Automatic Roof Seaming Machine | This machine is assistant equipment for roof roll forming machine. It is used to seam the roof panels. It is featured by lightweight, small size, e... | |

| CABLE TRAY ROLL FORMING MACHINE | Well designed by engineers at Hangzhou Roll Forming Technology, this series of cable punching machines can produce rolling cable tray and caps from... |

Same products

| Cable Pulling Sock | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Pulling Sock CABLE PULLING SOCK: The is the most ideal tool designed for electrical a... | |

| Side Dragging Cable Grip | Seller: Hebei Long Zhuo Trade Co., Ltd | Side Dragging Cable Grip Side Dragging Cable Grip SGA/MGT/SK/MK is also called cable sock w... | |

| Cable Pulling Grips TG MG TGM TGK | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Pulling Grips TG MG TGM TGK Head Traction Cable Grip TG/MG/TGM/TGK Cable grips are a ... | |

| Cable Grip Supplier | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Grip Supplier Cable Grip: A Reliable Solution for Safe Cable Pulling and Handling A... | |

| Cable Roller Manufacturer | Seller: Hebei Long Zhuo Trade Co., Ltd | Cable Roller Manufacturer Cable Roller: Essential Equipment for Safe and Efficient Cable Ins... |