Ceiling panels roll forming machine with hydraulic profile cutter,Ceiling panels roll forming system

Ceiling panels roll forming machine working flow

Decoiling steel sheet →covering film→pre-cutter→Guiding system→Roll forming→Cut to length→Run out table

Machine components

A)Decoiler:

a)Loading capacity: ≤2T

b)Suitable material ID: φ508mm

c)Suitable material width: 300mm

d)Suitable material OD: <φ1000mm

e)Manual passived decoiler

B) Main machine forming system:

1. Guiding platform

It is set in the beginning of the main machine with left-right guiding. It can help the operator to make the sheet in the right direction, left side and right side can be adjusted separately by manual screw structure.

2. Pre-cutter system

This device is use to cut the steel sheet material while the sheet into the roll forming machine and need finish the work.

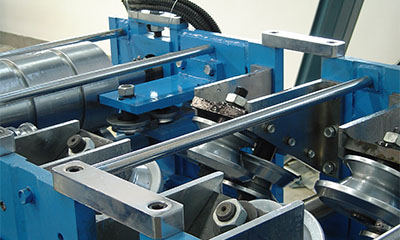

3. Roll forming system

Roll forming system consist of machine frame, transmission parts and roll forming rollers etc.

a) Machine frame adopts welding structure with blasting treatment.

b) The roller of this line is made of No.45 steel, surface painted with hard chrome, all treated by full CNC precision machines, therefore the roller has good rigidity.

c)Roller supporting type: column

d) Electrical motor driving, the back/forward roller driven by chain, part of upper/lower rollers driven by gear

e) Adjust the screw bar manually to adjust the distance between upper/lower rollers for difference thickness of sheet.

f) Different thickness and yield stress will get different dimension tolerance.

C) Hydraulic profile cutter

The hydraulic profile cutter could cut the sheet according to preset length.

D). Runout system

There will be one table to hold the run out panels, 6m length

E). Hydraulic system

1. Hydraulic profile cutter adopts separated inside set hydraulic station

2. Main valve and pump

F) .Electrical control system

1. Adopts PLC control technology which can ensure the automatic producing.

2. The system provides friendly man-machine interface which can set the batches, plate length, quantity and so on.

3. Operation type: Input touch screen+button

4. Encoder calculates the number, which has function of calculation and measuring the length.

5. Adopt Mitsubishi PLC and inverter.

Other supplier products

All supplier products

Same products