High Speed Tube Mill Line

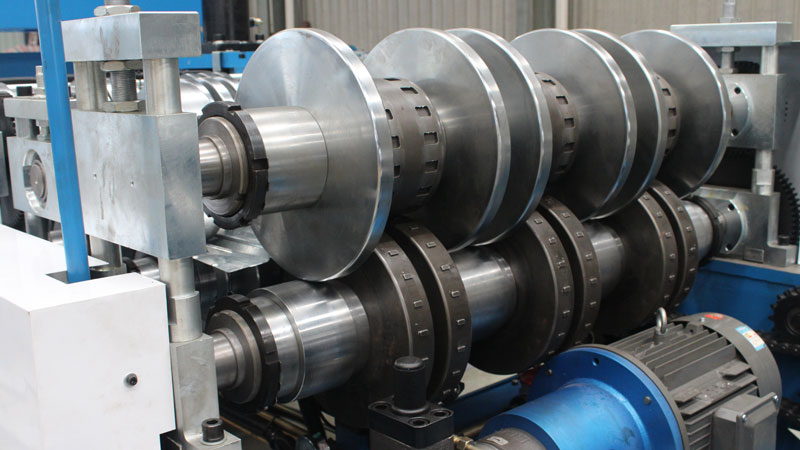

High Speed Tube Mill Line is used to produce tube diameter between φ4mm to φ50mm. The top working speed can be 120m/min to 130m/min.

Working Flow of High Speed Tube MillLine

Decoiling

Shear and butt welding

Accumulator

Roll forming

High frequency ERW

Removing burrs

Cooling

Sizing

Flying saw

Conveying

Downloading

Packing

Warehousing

Main technical parameters (For reference only, will be as requests):

A: suitable strip coils

Alloy Steel Coil; API5L X42-X80

(For reference only, will be as requests)

- φ4mm-φ50mm

Length: 6m-12m

Length tolerance:+/-3mm

Production speed: 120-130m/min

Direction: Left to right or right to left from operator's side(as requests by customer)

Capacity: 10,000 ton/year-15, 000 ton/year

Electricity input power: 50kW-65kW

Foundation: 40m–50m (length) x 3.8m-4m (width)

Weight: About 30ton–300ton.

Operator: 6-8 people (as size requests)

Tube mill line china/pipe mill china line from Hangzhou Roll Forming Technology Co., Ltd adopts mature, reliable, completed, economical and advanced process with advanced furnishments to ensure the tube pipe mill to reach a relatively advanced level not only in quality and cost but also consumption so that the products have strong competitive power in quality and price.

Send product request

Other supplier products

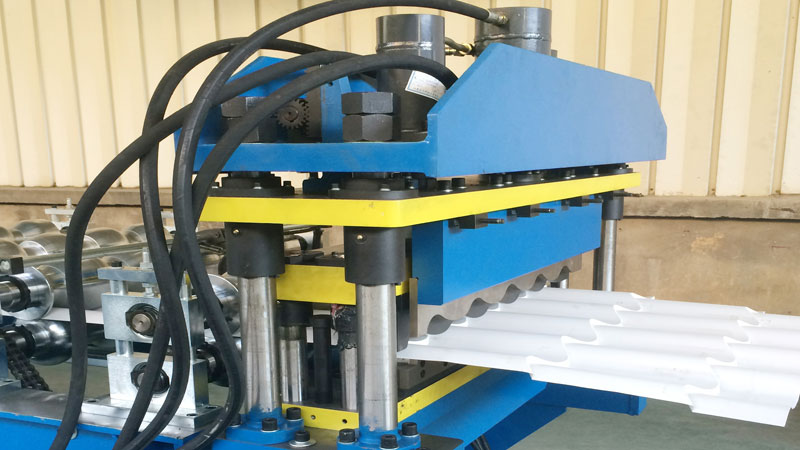

| HIGH SPEED ROOFING TILE MAKING MACHINE | The high-speed metal roof tile machineis for continuously roll forming and pressing step tiles sheets. The step length of this series can be set up... | |

| HYDRAULIC AUTOMATIC SHEAR AND BUTT-WELDING MACHINE | The shear and hydraulic butt welderis the important equipment on the welded pipe production line. It is used for the shearing and butt welding of t... | |

| Metal Deck Roll Forming Machine | The metal deck roll forming lineis a steel structure building material produced by cold roll forming, which is used for supporting floor concrete i... | |

| Top Grade Deck Floor Roll Forming Machine | Features and Advantages of Top Grade Floor Decking Forming Machine Fully automatic continuous decking forming machine. Cassette type platform quick... | |

| C/U/Z/M Purlin Roll Forming Machine | Hangzhou Roll Forming Technology Co., Ltd is a professional manufacturer and exporter of all kinds of standard and non-standard cold roll forming l... |

Same products

| Brown Fused Alumina For Abrasive | Seller: ZHENGZHOU HAOYUN NEW MATERIAL TECHNOLOGY CO., LTD. | Cooled and smelted under an electric arc at a high temperature above 2000 degrees, brown fused al... | |

| Brown Fused Alumina | Seller: ZHENGZHOU HAOYUN NEW MATERIAL TECHNOLOGY CO., LTD. | What is brown fused alumina Brown fused alumina is a versatile product available in various form... | |

| Ceramic Kitchen Knife Set | Seller: Yangjiang Bohao ENTERPRISE CO., LTD | Ceramic Kitchen Knife Set This ceramic knife setof 4 knives with a peeler set is enviably stylis... | |

| Magnetic Welding Holders | Seller: NingBo BeiLun Meank Magnetics Co.,ltd. | We have different types of magnetic welding holder for saleat Meank China welding magnetic hook f... | |

| Dust Test Chamber | Seller: Xi’an LIB Environmental Simulation Industry | LIB Industry offers a wide range of dust test chambers with different sizes and configurations to... |