Electric Arc Furnace Waste Heat Recovery Boiler

Electric Arc Furnace Waste Heat Recovery BoilerNecessitySteel & iron making accounts for 12% ~ 15% of the entire domestic energy consumption annually,Website:, and around 10% of this huge production comes from EAF (2009). The dust-laden flue gas temperature is approximately 1000℃ ~ 1450℃ which has been traditionally treated by series of water-spraying to lower its temperature down to 130℃. This traditional method requires extra energy input and leads to a tremendous water wastage, for which a quality waste heat recovery system is a responsible choice to make. Design IngenuityBoth flue gas quantity and temperature emanating from the EAF fluctuate along with the smelting cycle. Moreover, gas contains a large portion of dust particles, rendering heat surface (heat exchange surface) susceptible to fraction. Our heat surface area employs a unique multi-free-end-surface design, meaning that the heat surface is able to stretch flexibly within a safe interval as the heat expansion frequently takes its place. Our boiler is also designed with optimal flue gas velocity to ensure the long lifespan of the entire heat surface. The average investment recovery period is 3 to 4 years. Key Parameters1 T of steel production = 150 KG ~ 250 KG of steam output Applicable furnace capacity: 70 T ~ 350 T Rated operating pressure: 1.0 MPA ~ 3.0 MPAPROJECT EAF WASTE HEAT RECOVERY FOR:JIANGSU YONGGANG GROUP CO., LTD. (YONG-STEEL)Rated steam pressure: 3.0 MPA Working steam pressure 1.2 MPA ~ 1.6 MPA Rated steam temp: 235.7 Deg Celsius (saturated temp)1 T of steel production = 180 KG of steam output

Other supplier products

|

|

Sinter Cooler Waste Heat Recovery Boiler |

Sinter Cooler Waste Heat Recovery BoilerNecessitySinter Cooler process is highly energy consuming and it accounts for 10% of the entire energy inpu... |

|

|

Boiler Membrane Wall |

18.Boiler Membrane Wall Boiler membrane wall sections are processed with automatic submerged arc welding technology and pipe panels are adjusted by... |

|

|

Cement Kiln Waste Heat Recovery Boiler |

Cement Kiln Waste Heat Recovery Boiler NecessityThe cement production industry results in massive energy waste and environmental pollution during i... |

|

|

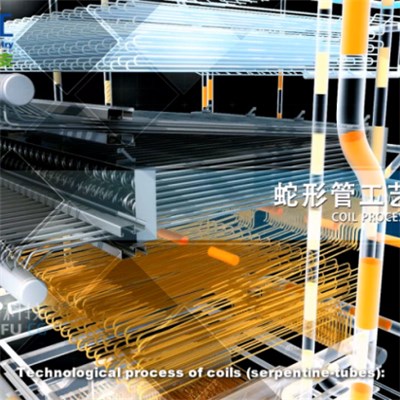

Boiler Serpentine Coils |

Boiler Serpentine CoilsBoiler serpentine coils are processed by advanced automatic assembly line technology,Website:, from tube-polishing to the fi... |

|

|

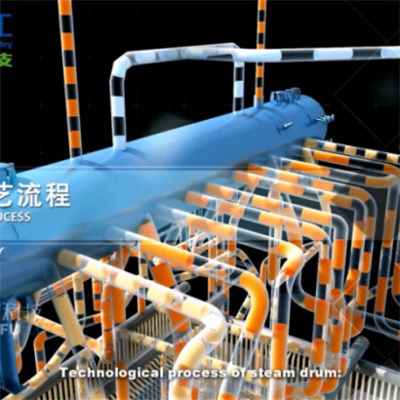

Boiler Drum |

boiler drumBoiler drum is processed by laser CNC gas-cutting technology. Preliminary material preparation is conducted as per required drawings dim... |

All supplier products

Same products