Drill Bits Application In The Water Well Industry

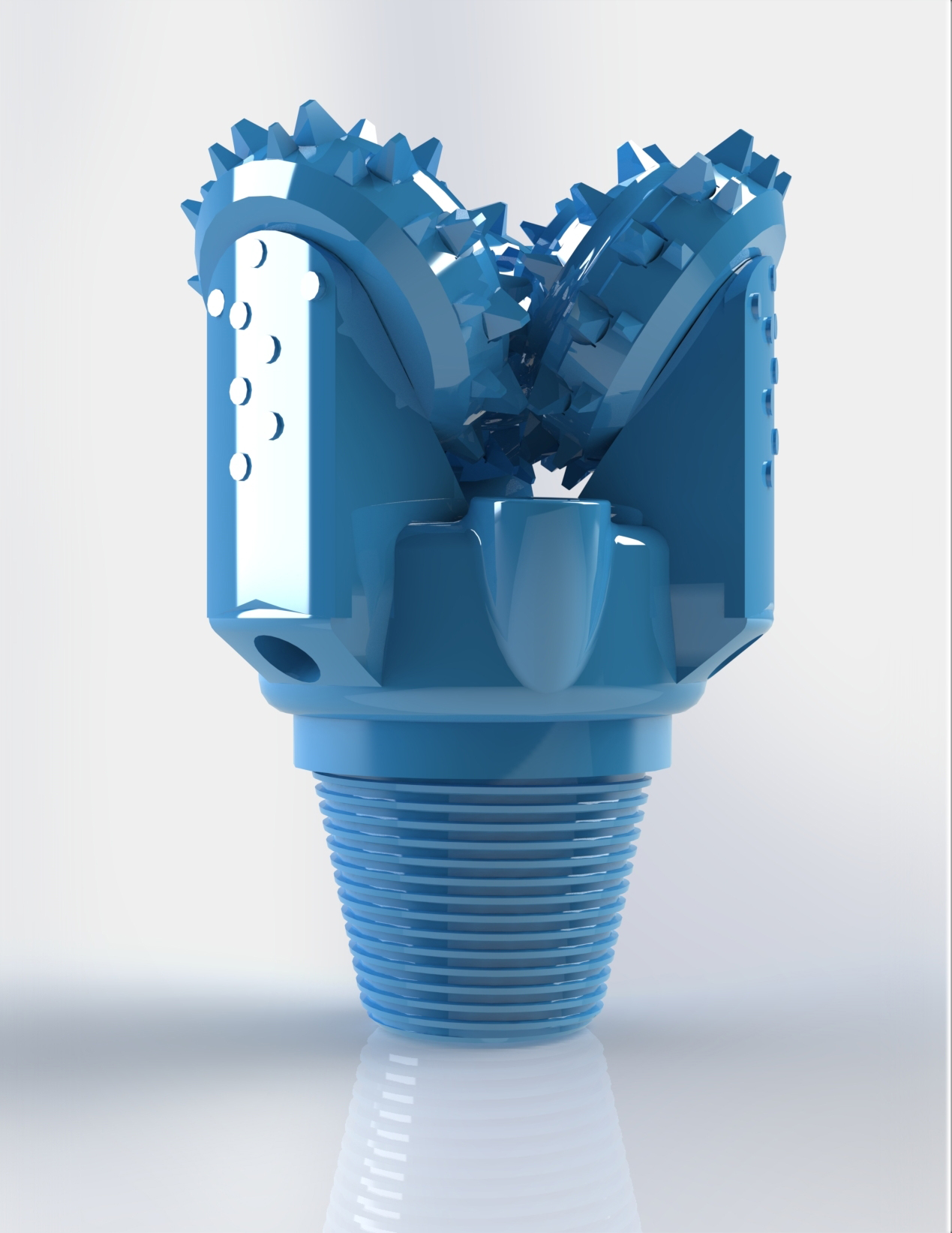

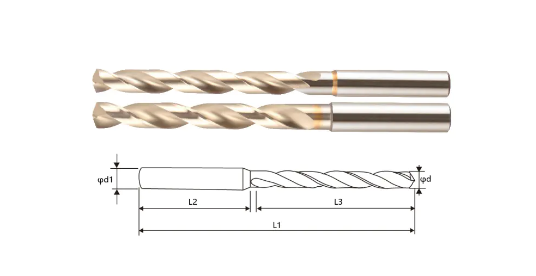

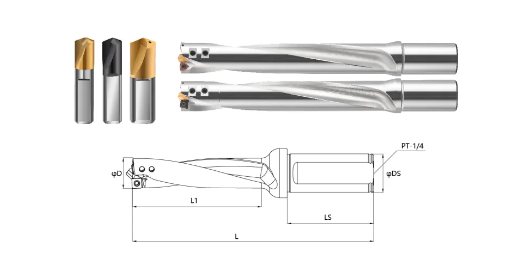

During the construction of a water well drilling rig, the drill bit is mainly used to break the rock, and the quality of the drill bit directly affects the drilling speed, drilling cost and wellbore quality. The selection of water well drilling bits types with fast drilling speed and long service life for water well drilling rigs can greatly reduce drilling costs. Drill bits for water well drilling are mainly divided into scraper bits, roller cone bits, diamond bits, carbide bits, PDC bits and special bits, etc. These bits have their own rock breaking principles and applicable formations. In recent years, the continuous innovation of water well drilling rig products has led to the rapid development of drill bit water well research and development technology. At present, there are some new PDC drill bits and hybrid drill bits that can be widely used in various formations.

Advantages of PDC Bit for Well Drilling

PDC bits for well drilling are widely used because of high efficiency and low cost, especially in recent years the price of drill bits is gradually declining, its application can already completely replace manual drilling. As the drilling of water wells for the bottom of the well water output requirements are relatively high, so drilling bits will generally choose large-diameter PDC bits. After the well is drilled with PDC bit, the pump is then put into the well to extract groundwater for people's living and irrigation. The location of the well's outlet varies in different areas, and sometimes the groundwater level varies in different directions in the same area.

Precautions for drilling water wells with PDC bits

Generally speaking, the water level of this well is above 100 meters. Therefore, in order to avoid the well water not being drained or scrapped, attention should be paid to:

Prevent groundwater from entering the pit.

Prevent the slope from collapsing due to the loss of groundwater pore space.

Pay attention to clean up the soil layer at the bottom of the well to avoid the pressure caused by the groundwater level gap, resulting in the phenomenon of pipe surge at the bottom of the well.

After settlement, the lateral bearing capacity of sheet pile is reduced.

Eliminate groundwater seepage and prevent sand flow.

It should be noted that when some strata soil or geological conditions contain a small amount of stones, it is necessary to use PDC bits to drill the well.

As one of pdc bit manufacturers, we can offer kinds of borehole drilling bits for sale , if you have needs, please contact us.

More different water well drilling bits types, please visit our website.

Other supplier products

|

|

PDC CORE BIT |

PDC core bits, also known as hollow bits, are tubular multi-toothed instruments embedded with carbide chips. Outfitted with carbide inserts, they e... |

|

|

Drill Bits Application In The Water Well Industry |

During the construction of a water well drilling rig, the drill bit is mainly used to break the rock, and the quality of the drill bit directly aff... |

|

|

Steel Tooth Tricone Bit |

The teeth are processed by milling, and the teeth are all wedge tooth.

Using floating bearing structure.

Using high -density metal sealing.

... |

|

|

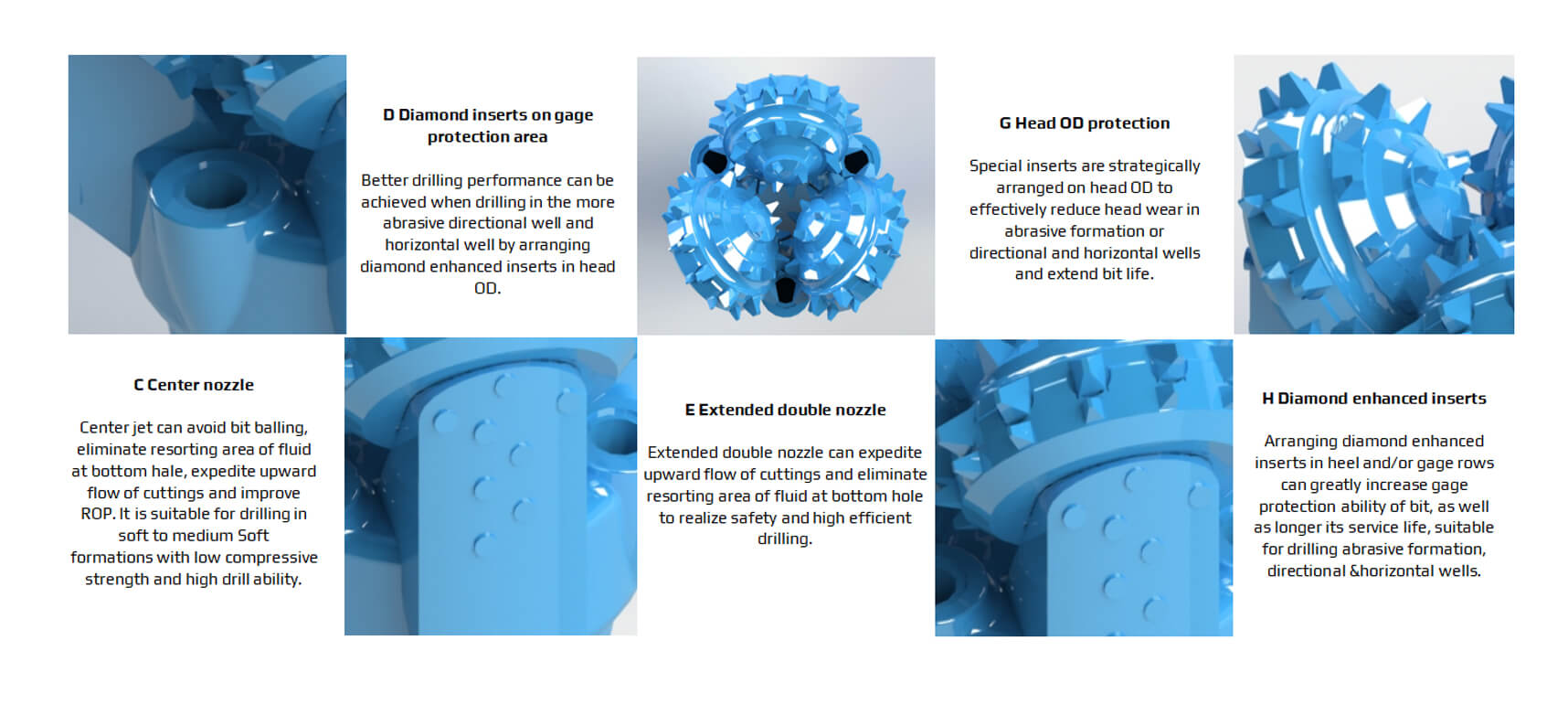

TCI BIT |

The tci tricone bithas the characteristics of wide adaptability to the stratum and high mechanical drilling speed. As a TCI/MI tricone drill bit ma... |

|

|

Steel Tooth Tricone Bit |

The teeth are processed by milling, and the teeth are all wedge tooth.

Using floating bearing structure.

Using high -density metal sealing.

Stee... |

All supplier products

Same products