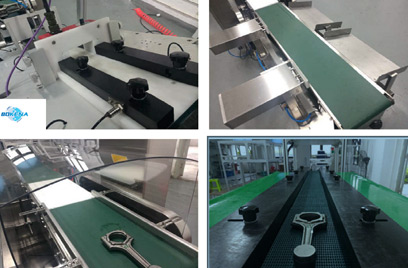

Eddy Current Testing Equipment for Tube, Bar and Wire 1024

We have eddy current equipment for sale!

ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals to detect. It is one of the NDT non-destructive testing methods in the industry.

We can use different coils according to the shape of the specimen and the purpose of detection. There are usually three types of coils: through a coil, probe coil and insert coil. It is mainly used for the rapid detection of metal pipes, rods and wires on production lines, and for the detection of large quantities of parts such as bearing steel balls, valves, etc.

The main features of eddy current tester are:

1) The detection sensitivity of the surface of the conductive material and the near surface defects is high;

2) A wide range of applications can be monitored for various physical and technological factors affecting the characteristics of induced eddy currents;

3) It is easy to realize high-speed, high-efficiency and automatic detection of tubes, rods and wires without using a coupling agent;

4) Under certain conditions, it can reflect information about the crack depth;

5) Monitoring can be carried out in the case where other detection methods such as high temperature, thin-walled tubes, thin wires, and inner surface of the parts are not applicable.

Eddy current testing equipment for tube, bar and wire including BKNET-999/H Copper Tube Eddy Current Flaw Detector, GSET-551steel wire eddy current testing, BKNET-101 Automatic Eddy Current Flaw Detector, Rod Tube Rotary Eddy Current Flaw Detector ET-R-15/40/65/90, BKNET-01�2 Welded Pipe Eddy Current Flaw Detector, LGET-553 Aluminum Tube Eddy Current Flaw Detector.

These equipments are mainly applicable to the surface defect detection of ferromagnetic non-ferrous metals, austenite, stainless steel tubes, rods and discs. It can be widely used for on-line or off-line NDT non-destructive testing of raw materials in energy, petrochemical, bearing, automobile, transom manufacturing, household appliances and other industries, such as bearings, raw materials of high strength bolts, copper, aluminum tubes of various refrigeration equipment, condenser tubes of evaporators, etc. This system is the necessary testing equipment for pipe and bar and wire production and application factory. This system adopts rotating balance point probe, resolver signal coupling, synchronously adjusting double detection probe, and the detection method of workpiece passing straight line. It has the characteristics of stable and reliable performance, high detection sensitivity, fast detection speed, no need for magnetizing and demagnetizing devices, and is sensitive to defect detection of pipe, bar and wire. It can make 100% NDT non-destructive detection of raw material surface. The equipment has the functions of defect alarm, automatic feeding and unloading and automatic sorting to achieve the detection automation. It provides an effective detection means for mass production of application pipes, rods and wires in factories and enterprises to ensure quality.

As one of the most professional ndt testing equipment suppliersin China, BKNhas formed a social scientific research cooperation network with well-known universities and research institutes in China, which has a strong R&D and production capacity. It guarantees the leading and word-class technology position of BKN industrial nondestructive testing technology.

Send product request

Other supplier products

| GTET-02 Cylinder Liner Eddy Current Testing Machine | Bokena has eddy current equipment for sale! GTET-02 Cylinder Liner Eddy Current Testing MachineIntroduction Detection method Eddy current testing... | |

| EDM Notch 1024 | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... | |

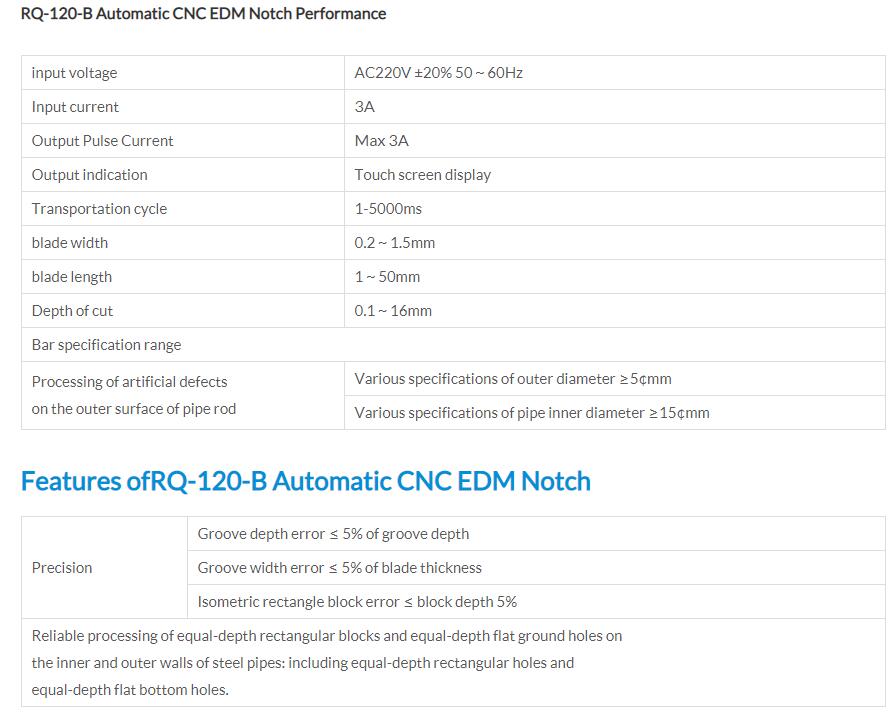

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| Application of Ndt Inspection Equipment | Application of Ndt Inspection Equipment Ndt inspection equipmentis widely used in industry, such as nuclear industry, weapon manufacturing, machin... | |

| GSET-551 Steel Wire Eddy Current Flaw Detector | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Introduction Using the eddy current signal processing method and high-performance DSP algor... |

Same products

| Cash Register Scale BL-A | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | The Cash Register ScaleBL-A features a large touch screen display, available in either a 12.1" or... | |

| Cash Register Scale GL-A | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | The Cash Register ScaleGL-A is equipped with a capacitance touch screen, which solves the problem... | |

| TDP-B+ Electronic Price Computing Apparatus | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | The TDP-B+ digital price computing scaleis a versatile device that offers optional digital filter... | |

| Cash Register Scale ADS-P | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | The Cash Register ScaleADS-P is a user-friendly and efficient weighing device that simplifies the... | |

| Double Printing Cash Register Scale DL-A | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | Two-in-one checkout and labeling. The Double Printing Cash Register Scale DL-A is a multi-functio... |