GSET-551 Steel Wire Eddy Current Flaw Detector

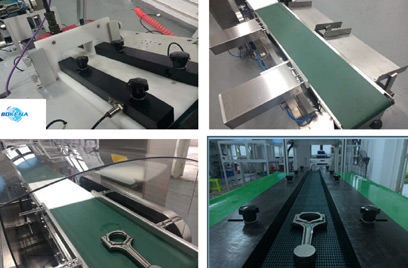

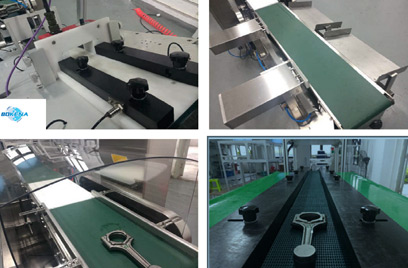

GSET-551 Steel Wire Eddy Current Flaw Detector Brief Introduction

Using the eddy current signal processing method and high-performance DSP algorithm, the NDT wire rope testerdetection ability of micro-crack is as high as 0.05mm deep crack.

Using computer digital technology and "digital eddy current detection technology" to achieve high-speed data processing capabilities, detection speed can be reached to 1~500m/min. Technology can effectively suppress all kinds of interference signals. It has waveform, amplitude, phase, X-axis and Y-axis signals.

The professional "digital filtering" is adopted to effectively suppress the interference signal in the field and ensure the accuracy and stability of the detection.

Features of GSET-551 Steel Wire Eddy Current Flaw Detector

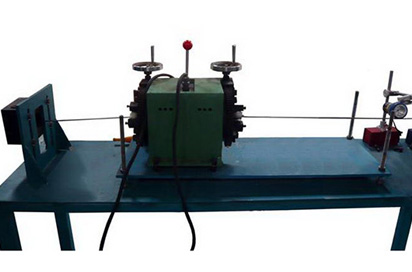

The detector detects the minimum metal cross-sectional area change and the minimum length of the damage length corresponding to the local damage.

The detector detects the minimum metal cross-sectional area change and the damage length minimum size corresponding to the metal cross-sectional area loss.

The maximum value of the random error obtained by performing multiple consecutive measurements of the same metal cross-sectional area change in the same test sample under the same test environment and conditions within the instrument range.

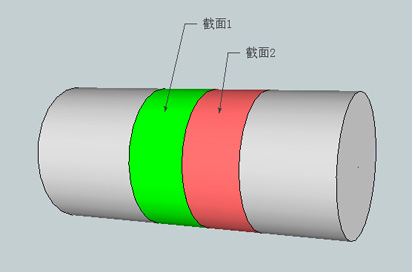

Within the range of the instrument, the metal cross-sectional area of the test sample is linearly proportional to the absolute value of the maximum deviation between the measured curve of the instrument and the calibration curve fitted by the measured value of the cross-sectional area of the metal.

The value of the metal cross-sectional area loss measured by the instrument minus the actual value of the metal cross-sectional area loss within the instrument's range.

In the range of the instrument range, under the condition of the length loss of the cross-sectional area of the metal, the cross-sectional area loss of the metal on the wire rope measured by the detector is matched with the value of the loss of the cross-sectional area of a group of wire ropes measured by the instrument. The absolute value of the maximum deviation between the calibration curves.

The detector is capable of detecting the resolved minimum distance.

The detector can detect and display changes in metal cross-sectional area loss (LMA) on one channel, and detect and display local damage (LF) on the other channel. The detector recording device can be a computer, graphic recorder or other matches. device.

The detector cannot simultaneously detect and display metal cross-sectional area loss changes and local damage, and can only detect and display one of them. The detector recording signal device can be a computer, a graphic recorder or other matching devices.

The detector principle and composition meet the requirements of the GB/T 21837-2008 standard, and it has a detector for detecting distance display, data storage or recording function.

As one of the most professional mfl suppliers, BKNprovidesndt testing machine, wire rope ndt, eddy current testing, etc. Want to know more? Please contact us.

Send product request

Other supplier products

| BKNET-999H Copper Tube Eddy Current Flaw Detector | BKNET-999H Copper Tube Eddy Current Flaw Detector brief Eddy current testing is a non-destructive testing technique in which an alternating curre... | |

| Eddy Current Testing Equipment | Are you looking for a perfect eddy current testing machine manufacturer? BOKENAis one of the most professional eddy current test equipment supplier... | |

| Magnetic Flux Leakage Testing Equipment | BKN is one of professional ultrasonic testing equipment manufacturers. We provide Magnetic Flux Leakage Testing, ndt ultrasonic testing equipment, ... | |

| GSET-551 Steel Wire Eddy Current Flaw Detector | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Introduction Using the eddy current signal processing method and high-performance DSP algori... | |

| Wireless Transmission Pipe Ultrasonic Flaw Detector | The ultrasonic pipe testing equipmentsystem is suitable for the automatic detection of various internal and external defects of steel pipes. The pr... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |