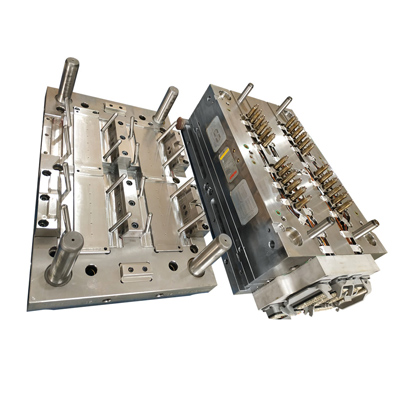

3 Plate Mould 49113-21

Mould Name: 3 Plate Insert Mould

Part Material: PBT GF15

Product Size: ф34.9x82.29

Product Description: Mischschraube kpl

Mould Cavity: 2 Cavities

Mould Size: 250*230*350 MM

Mould Cavity Steel: 2343 ESR

Mould Injection System: 3-Plate point gate

Mould Ejection System: Round ejector

Mould Cycle Time: 28's

Mould Life Cycle: 500,000

Lead Time: 45 working days

Mould Features: insert molding

mold 3 plateis also called pinpoint gate mould.

There are two parting surfaces to divide the mold into three parts. Compared with the 2 plate mould, the gate plate of three plastic plate mouldis added. It is suitable for the molds that do not allow gate marks around the product. This type of mold uses a pointed gate, so it is called pinpoint gate mold.

The typical three plate mouldmovement process

The mold opening process: the three-plate mold has two parting processes, the first between the stripping plate and the cavity plate, and the second time between the cavity plate and the core plate. When the core side is pulled by the injection molding machine, as the A and B plate are equipped with a latch lock, and there is no connection or obstruction between the stripping plate and the A plate (in most cases, the pull rod is also equipped with a spring) At this time, the stripping plate is first separated from the cavity plate by the pulling force, and the cavity plate moves backward with the core plate. When moving to the set distance, it is blocked by the pull rod limiting block, because the A plate continues to move with the injection molding machine. Therefore, the pull rod is also driven, and the pull rod drives the stripping plate to move to the next set distance and then the pull rod and the cavity plate stops moving.

The injection molding machine continues to move backward, as the pulling force continues to increase, exceeding the locking force of the latch lock, the A plate is separated from the B plate, and stops when the set distance is reached.

The ejector plate drives the ejector mechanism (the ejector pin, the ejector rod, and the lifter) to start the ejection movement, and the finished product is ejected (automatically dropped or removed by the robot).

Clamping process - When there is a pullback mechanism on the ejector plate, the ejector plate is forcibly pulled back by the injection molding machine before clamping.

Under the push of the injection molding machine, the core moves forward to the cavity side, if the ejector plate is not pulled back in advance, the return pin first contacts the cavity plate. Under the reaction force, the ejector plate is returned by the return pin.

The B plate is pressed against the A plate and the stripping plate, and finally completely tight. The nozzle on the injection molding machine is closely fitted with the nozzle bushing on the mold, and the next cycle of injection molding is started.

Following the concept of customer first, hanking molddedicates to be a trustworthy tooling company by designing and manufacturing plastic injection molds, providing custom plastic molding manufacturing and services according to every individual's requirements. Hanking's successes are ensured by our management capability, technical knowledge, advanced plastic tooling equipment and professional injection molding services. We are pursuing better quality and technical capability to meet the demands of increasing mold making markets.

We are a responsible chinese molding companiesand mold maker company in China and have experience in supplying custom plastic injection molding service for many years. Our production sites have been accredited the certification of TS16949, ISO 14001 and ISO 9001, etc. You can fully trust our production sites, products and place your orders.

Send product request

Other supplier products

| Home Appliance Molding Parts | As one of the most professional Chinese molding companies, we offer various plastic moldingwith high-quality, plaese do not hesitate to contact us.... | |

| Double Injection Mold Parts | Double Injection Mold Parts Part function: Plastic Lid for coffee machine Part Standard according to ISO 11496 Surface: SPI A-2 finish Flammabil... | |

| Double Injection Mold Parts | Details OfDouble Injection Molding ProcessPart function: Plastic Lid for coffee machine Part Standard according to ISO 11496 Surface: SPI A-2 finis... | |

| Multi Cavity Mould | 24 Cavities Plastic Injection Mold Product Name: 24 Cavities Plastic Injection MoldMold Base: LKM, HASCO, DME, etc.Mold Steel: NAK80, ASSAB8407, S1... | |

| Sewing Machine Frame Mould | Sewing Machine Frame Mould Large plastic frame plastic injection sewing molds, suited for oversize embroidery projects. Mould Name: Embroidery ... |

Same products

| AIT500-SG High-Precision Current Sensor Transducer | Seller: Shenzhen Hangzhi Precision Electronics Co., Ltd | AIT500-SG has a high gain and measurement accuracy in the full bandwidth range, due to theapplica... | |

| JWA2-M Oil Micro Moisture Sensor | Seller: Shenzhen Joinwe Smart Co.,Ltd | JWA2-M micro moisture sensorcan quickly and accurately detect oil water activity (moisture satura... | |

| Made in China Displacement sensor 4000TDG for thermal power plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Made in China Displacement sensor 4000TDG for thermal power plant YOYIK professional production ... | |

| China made Control System LVDT 5000TDGN for power plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China made Control System LVDT 5000TDGN for power plant Dongfang Yoyik has advanced technology a... | |

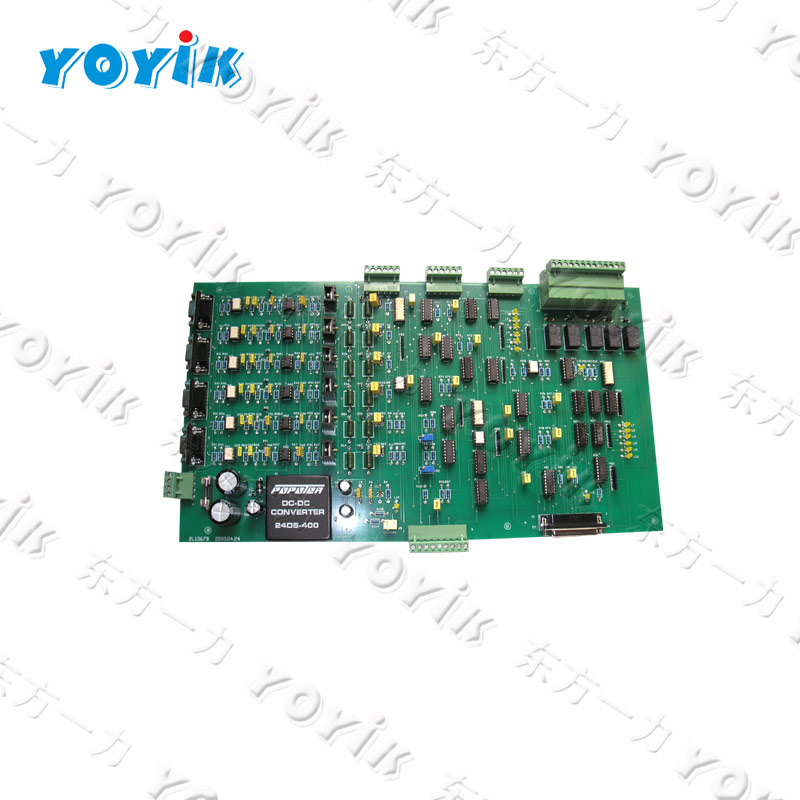

| China supplier main control board APF7.820.117A-A power plant spare parts | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China supplier main control board APF7.820.117A-A power plant spare parts Dongfang Yoyik is spec... |