Car Knock Sensors

The car aftermarket knock sensoris an AC signal generator, which can detect the speed and position of the rotating shaft, vibration or mechanical pressure. It's also a piezoelectric device. They are made of special materials that can sense mechanical pressure or vibration, for example, AC voltage can be generated when the engine starts knocking.

When the engine vibrates or knocks, the piezoelectric ceramics produce a voltage peak. The greater the knock or vibration, the greater the peak. The engine control unit ECU processes the received signal from the automotive knock sensors. If it judges that knock occurs, it will delay the ignition time and prevent further knock. When ECU does not receive the signal from the automotive knock sensors, it will advance the ignition time to ensure the best power output of the engine.

The car knock sensorfrom MAPMS auto sensors provides knock signal to the ECU and reminds ECU to readjust the ignition timing to prevent further knock.

Knock SensorsFeatures

Accurately measure engine shake.

Precise adjustment of ignition advance angle.

Durable and not easily damaged.

What Are the Symptoms of a Bad Auto Knock Sensor?

Auto Knock Sensor is used to measure the engine jitter and adjust the ignition advance angle when the engine produces knock. If there is a fault, the engine deflagration signal cannot be detected and the ignition time cannot be postponed automatically. Judge whether there is a fault through the following phenomena.

Knock Engine of automotive knock sensor

When the engine is working, engine knock will be caused by excessive ignition time advance (ignition advance angle), engine load, temperature and fuel quality. In case of knock, before the piston moves to TDC, the light one will produce noise and reduce the power of the engine, the heavy one will damage engine mechanical parts.

ECU Cannot Monitor the Degree of Deflagration

In case of damaged, ECU cannot monitor the degree of deflagration, it will reduce the ignition advance angle, when ECU detects that the engine has deflagration through the deflagration sensor, so it is wrongly judged that there is no deflagration. In this case, ECU will increase the ignition advance angle and cause the engine to work rough and shake due to deflagration.

Automatic Delay Ignition Time

Automatically delay the ignition time to prevent engine detonation. Therefore, the engine will be in the working state of ignition delay. The fuel consumption will increase, combustion energy rate will decrease, and engine power will decrease.

If you need any kinds of car spares and parts, please contact us, as one of the most professional auto spares suppliers, MAPMS is willing to offer you high quality products.

Send product request

Other supplier products

| Car Engine Oil Filters | Under normal circumstances, the operation of engine parts will produce metal debris, incoming dust, carbon deposits oxidized at high temperatures, ... | |

| Auto Relays | Auto off relay control higher voltages or currents by using lower voltages or currents. When a certain voltage or current is applied to both ends o... | |

| Neutral Safety Switches | The neutral safety switch relay is one of the vehicle safety switches to prevent accidents, which plays a role in safety protection. When the vehic... | |

| Auto Car Thermal Expansion Valves | The auto ac expansion valve of the automotive air conditioner is installed at the entrance of the evaporator, and has two main functions. Throttle... | |

| Tire-Pressure Monitoring System (TPMS) | The system has become a mandatory configuration for new vehicles throughout the United States and Europe. It is directly integrated in the on-board... |

Same products

| AIT500-SG High-Precision Current Sensor Transducer | Seller: Shenzhen Hangzhi Precision Electronics Co., Ltd | AIT500-SG has a high gain and measurement accuracy in the full bandwidth range, due to theapplica... | |

| JWA2-M Oil Micro Moisture Sensor | Seller: Shenzhen Joinwe Smart Co.,Ltd | JWA2-M micro moisture sensorcan quickly and accurately detect oil water activity (moisture satura... | |

| Made in China Displacement sensor 4000TDG for thermal power plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Made in China Displacement sensor 4000TDG for thermal power plant YOYIK professional production ... | |

| China made Control System LVDT 5000TDGN for power plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China made Control System LVDT 5000TDGN for power plant Dongfang Yoyik has advanced technology a... | |

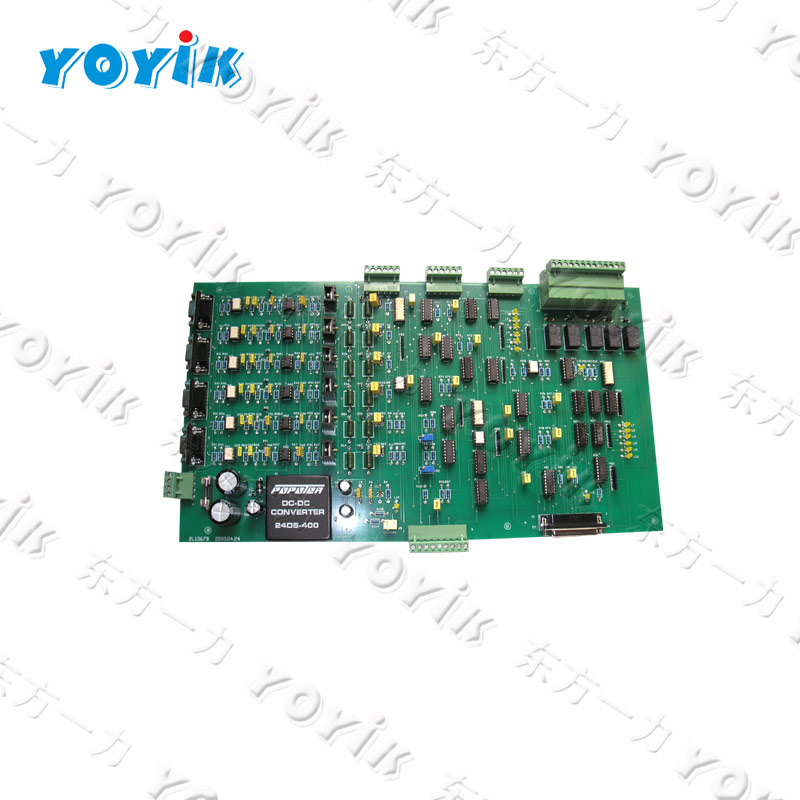

| China supplier main control board APF7.820.117A-A power plant spare parts | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China supplier main control board APF7.820.117A-A power plant spare parts Dongfang Yoyik is spec... |