Types of PCBA Capability

A pcb assembly services (PCBA) is a printed circuit board populated with electronic components. It is a finished product that is ready for use.

The main difference between PCB and PCBA is that a PCB is an empty board, while a PCBA is a fully assembled board with components mounted on it. The components which are mounted on the board are usually soldered to the board and connected to each other. The components on the board are chosen according to the design of the circuit.

PCBA manufacturing is the process of creating a PCB from a design, which includes the processes of drilling, etching, and soldering of components. PCBA is the process of populating the PCB with components, and then soldering them onto the board.

PCB is the foundation of PCBA, as PCBA requires a PCB to be manufactured first. PCBA is the last step of PCB fabrication, and it involves more steps than PCB fabrication.

In conclusion, PCB and PCBA are two different stages of PCB fabrication. PCB is the first step and provides the foundation for the PCBA.

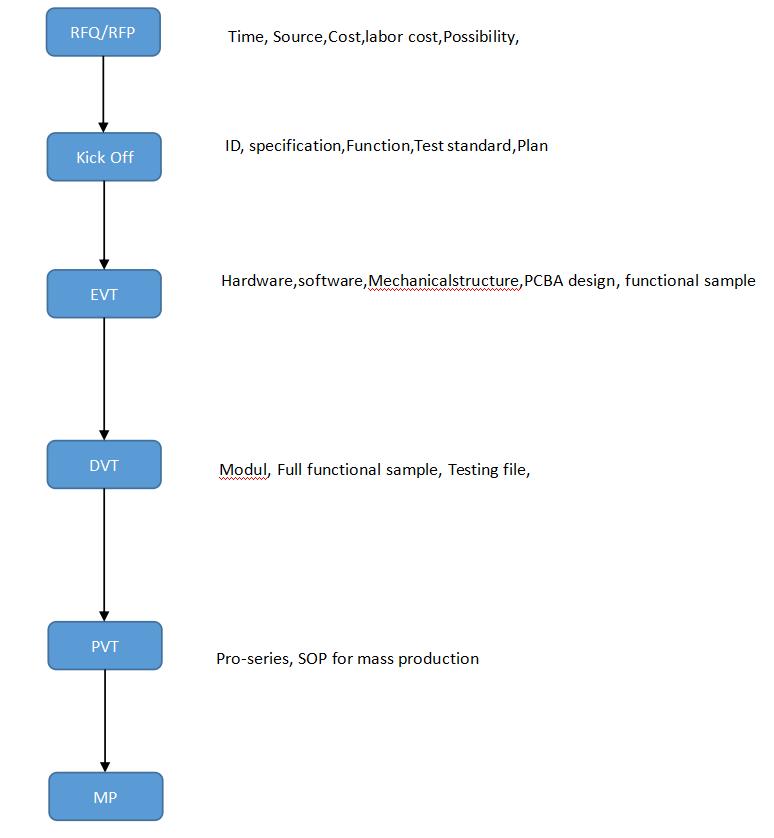

PCB Assembly Process & Applications

PCB assembly is the process of connecting and soldering components to printed circuit boards (PCB). This process starts with the selection of components and continues with the placement of components on the board, followed by soldering and inspection. Automated pick-and-place machines are used to place components on the PCB. The soldering process is usually done using reflow ovens, which use hot air to melt the solder. After the soldering is complete, the PCBs are inspected to ensure that all components are properly placed and soldered. The entire process is usually done in a cleanroom environment to ensure that components are not contaminated with dust or other particles.

Pcb design and assembly / pcb design & assembly (PCBA) is a process in which components are mounted onto a printed circuit board (PCB). In the PCBA process, components are soldered onto the PCB, allowing electrical signals and power to pass through the board. Once the components are soldered, the PCB is tested to ensure proper operation. The PCBA process is essential for most electronic assemblies, as it allows for the efficient and reliable transfer of electrical signals. Additionally, the PCBA process can be used to create complex and sophisticated electronic systems, like those found in modern consumer electronics. PCBA is used in a variety of industries, from consumer electronics to medical devices.

If you are looking for a reliable pcb assembly service factory / pcb assembly service supplier, don't hesitate to contact us!

There are many pcb assembly services manufacturers / pcb assembly services suppliers, but we are one of the best choices for you.

For more information about pcb production service and pcb assembly board, please feel free to contact us!

Send product request

Other supplier products

| PCB Design/Layout | Overview PCB design basics is a basic concept in electronics engineering that refers to the layout and design of printed circuit boards (PCBs). It ... | |

| PCB Design Process | PCB layout process Requirement of DFM All the DFM should apply with the cap For more information about globally sourced components and component ... | |

| 10-Layers Rigid-Flex PCB Green Cover Film White 1.5mm | Rigid-flex PCBs are used in many applications including aerospace, medical, telecommunications, and military. They are used when space and weight a... | |

| Golden Triangle Flex PCB Capabilities | Flexible printed circuit manufacturing processis a form of Printed Circuit Board (PCB) that is made of flexible, instead of rigid, material. This t... | |

| Flex PCB | Flex circuitPCBis a type of printed circuit board with a flexible base material, allowing the board to bend and fold. This type of circuit board is... |