Drilling Waste Management

GN Vertical Cutting Dryer is one of the popular products for OBM and SBM.As the developing for the evironment regulations,thedrilling waste managementhas become more and more import.As an international famous brand for solids control,GN has been developping products suiting for drilling waste management.Up to March,2012, GN Solids Control is the only one API Certified manufacturer who provide Vertical Cutting Dryer for drilling waste management.GN also have the H-I G Dryer Shaker,and Dewatering Centrifuges,Big Bowl Big Volume decanter centrifuge availalble for drilling waste management and solids control.

-

GN Vertical Cutting Dryer Brochure

-

GN Equipment Brochure

GN Vertical Cutting Dryer

The GN Vertical Cutting Dryer uses centrifugal force to dry drilled solids in oil or synthetic base fluids. Astainless steel screenbowl traps ¡°wet¡± solids and accelerates them up to 890RPM with G force up to 420. Liquid is forced through the screen bowl openings, while ¡°dry¡± solids are extracted by the angled flights attached to the cone, which rotate slightly slower than the bowl. Tungsten carbide protects the flights from abrasive solids and ensures long operational life. This aids in maintaining a constant gap between the scroll and screen bowl, which is crucial for Vertical Cutting Dryer proper operation. GN Vertical cutting dryer has been done strict balance testing for all major rotary components to minimize vibration & noisy.The Cutting Dryer is the ideal products for oil based drilling waste management.

GN 2nd Generation Vertical Cuttings Dryer Factory Testing?

|

|

GN Vertical Cutting Dryer fixed with individual oil lubrication system with automatic alarm for pressure limit. The main motor and oilpumpmotor is interlocked with each other for? avoiding the start of the main motor prior to the start of the oil pump motor.

| Model | GNCD930C | GNCD930C-VFD |

| Capacity | 30~50 Tons/H | |

| Drying Efficiency | OOC ¡Ü 5% | |

| Screen Max Diameter | 930mm | |

| Screen Opening | 0.25~0.5mm | |

| Rotation Speed | 900RPM | 0~900RPM |

| Oil Tank Capacity | 60L | |

| Air Knife Input Pressure | 0.69Mpa | |

| Air Knife Input Capacity | 1.8m3/m | |

| Flushing Pump Qty | 1pcs | |

| Main Motor | 55Kw (75HP) | |

| Oil Pump | 0.55Kw(0.75HP) | |

| Flushing Pump Power | 4Kw(5.5HP) | |

| EX Standard | ExdIIBt4 / IEC EX/ ATEX | |

| Electric Cabinet | Exd | PLC+Positive Pressurized |

| Weight | 5900Kg | 5700Kg |

| Dimension: L¡ÁW¡ÁH | 2750¡Á2130¡Á1800mm | |

?

GN Vertical Cuttings Dryer Features and Benefits

The GN Vertical Cutting Dryer uses centrifugal force to dry drilled solids in oil or synthetic base fluids. A stainless steel screen bowl traps ¡°wet¡± solids and accelerates them up 900RPM. Liquid is forced through the screen bowl openings, while ¡°dry¡± solids are extracted by the angled flights attached to the cone, which rotate slightly slower than the bowl.

- The flights are made from hard high chrome alloy material to be anti-abrasive from solids and?ensure long operational life vertical cuttings dryer.

- Air Knife is Provided for cleaning the screen to avoid screen blinding.

- Balance testing for all major rotary components to minimize vibration & noisy

- Individual oil lubrication system with automatic alarm for pressure limit.

- Screw conveyor installed under the dryer to pick up the dry solids for continues operation.

- Cleaning pump provided for avoiding solids accumulation in the cuttings dryer

GN Decanter Centrifuge for Drilling Waste Management

GN have the dewatering decanter centrifuge as well as the high speed for separation fine solids which can meet your applications for drilling waste management.You can use the centrifuge for polishing the drilling fluids recovered from the Vertical Cutting Dryer and send it back to active mud tanks.

For small size decanter centrifuge,please check:GN Decanter Centrifuge

Remarks, Economic Configuration decanter centrifuge are available:

| Model | GNLW363BG | GNLW363BG-VFD | GNLW453VFD | GNLW553VFD |

| Bowl Diameter | 360mm(14inch) | 360mm(14inch) | 450mm(18inch) | 550mm(22inch) |

| Bowl Length | 1271mm(50inch) | 1271mm(50inch) | 1540mm(61inch) | 1800mm(71inch) |

| Max. Capacity | 200GPM(45m3/h) | 200GPM(45m3/h) | 352GPM(80m3/h) | 484GPM(110M3/h) |

| Effective Capacity | 132GPM(30m3/h) | 132GPM(30m3/h) | 264GPM(60m3/h) | 400GPM(90m3/h) |

| Max Bowl Speed | 3900RPM | 3900RPM | 3200RPM | 3000PRM |

| Typical Bowl Speed |

3200RPM | 0~3200RPM | 0~2800RPM | 0~2500RPM |

| Max G-Force | 3063 | 3063 | 2578 | 2719 |

| Typical G-Force | 2062 | 0~2062 | 0~1973 | 0~1888 |

| Separation point | 2~5¦Ìm | 2~5¦Ìm | 2~5¦Ìm | 2~5¦Ìm |

| Differential Speed | 40 | 0~40 | 0~35 | 0~45 |

| Gearbox Torch | 3500N.M | 3500N.M | 7500N.M | 12000N.M |

| Gear Box Ration | 57:1 | 57:1 | 57:1 | 35:1 |

| Main Drive Motor | 37KW(50HP) | 37KW(50HP) | 55KW(75HP) | 90KW(120HP) |

| Back Drive Motor | 11KW(15HP) | 11KW(15HP) | 22KW(30HP) | 37KW(50HP) |

| Recommend Pump | 7.5KW(10HP) | 7.5KW(10HP) | 15KW(20HP) | 22KW(30HP) |

| EX Standard | ExdIIBt4 / IEC EX/ ATEX | |||

| Electric Carbinet | Exd Standard | PLC+Positive Presurized | ||

| Weight | 3500KG | 3400KG | 4580KG | 5840KG |

| Dimension | 3305x1638x1277mm | 3305x1638x1277mm | 3824x1798x1317 | 4293x1978x1381 |

?

GN HI-G Cuttings Dryer for Drilling Waste Management

TheGN Hi-G Dryer Shakeris with long shaker deck big capacity which is used for waste management to treat the drilling cuttings from the primary solids control equipments like shale shaker, desander desitler to dry the solids for transportation, and make the fluids easier for further treatment.The function of the HI-G Dryer is similar as Vertical Cutting Dryer.

|

|

|

?

| Model | GNZS594HGE-LD |

| Vibration Mode | Linear Motion |

| Capacity | 140m3/h (616GPM) |

| Vibration Motor | 2x1.94Kw |

| Screen Qty | 4pcs |

| Screen Size: L¡ÁW | 585¡Á1165mm |

| Screen Area | 2.73m2 |

| Adjust G Force | ¡Ü8.0G |

| Vibration Amplitude | 4.4~6.34mm |

| Deck Angle Range | -1¡ã~+5¡ã (Adjustable) |

| Feeding Type | Hopper Feeder |

| Feeding Height | 895mm |

| EX Standard | ExdIIBt4 / IEC EX/ ATEX |

| Weight | 1638Kg |

| Dimension: L¡ÁW¡ÁH | 2761¡Á1998¡Á1428mm |

?

GN Drilling Cuttings Screw Conveyor

GN Screw Conveyor is popular in the oil gas industry for transfer the drilling cuttings to feed to the cuttings dryer,and cuttings colletction box. GN designed 3 size of diamter, 12inch, 14inch,18inch, each size has 4 different length for option according to the drilling site of the customer

?GN Drilling Cuttings Screw Conveyor (Auger) Technical Parameters

| Model | Screw Diameter (Inch) |

Screw?Length (Ft) |

Capacity (Ton/Hour) |

Motor (Kw) |

Speed (Rpm) |

Weight (Kg) |

Dimension: L¡ÁW¡ÁH(mm) |

| GNSC12A-24 | 12 | 24 | 20 | 5.5(7.5HP) | 60 | 1426 | 9150¡Á450¡Á600 |

| GNSC12A-36 | 12 | 36 | 20 | 7.5(10HP) | 1855 | 12950¡Á450¡Á600 | |

| GNSC12A-48 | 12 | 48 | 20 | 11(15HP) | 2318 | 16750¡Á450¡Á600 | |

|

GNSC14A-24 |

14 | 24 | 30 | 7.5(10HP) | 1515 |

9200¡Á485¡Á650 |

|

| GNSC14A-36 | 14 | 36 | 30 | 11(15HP) | 2028 |

13000¡Á485¡Á650 |

|

| GNSC14A-48 | 14 | 48 | 30 | 15(20HP) | 2549 |

16800¡Á485¡Á650 |

|

| GNSC16A-24 | 16 | 24 | 45 | 11(15HP) | 1668 |

9200¡Á545¡Á680 |

|

| GNSC16A-36 | 16 | 36 | 45 | 15(20HP) | 2269 |

13050¡Á545¡Á680 |

|

| GNSC16A-48 | 16 | 48 | 45 | 18.5(25HP) | 3344 |

16950¡Á545¡Á680 |

|

| Remark: | ?Capacity is for horizontal layout at 60RPM | ||||||

Note: Electrica specs for 380V/50Hz, 460V/60Hz or Customized

?????????? Screw material wear-resisting 16Mn

?????????? Each section standard length and interchangable

GN Drilling Cuttings Screw Conveyor

GN Solids utilize a custom designed and constructed Screw Conveyor (Auger) as part of drilling waste management system. The Drilling Cuttings Auger is designed with 12 feet per section which makes it to be standard spare parts for exchange with each other. The screw material utilized by GN is abrasive material which lasts longer than our competitors. The Drilling Cuttings Screw Conveyor (Auger) is designed to offer an efficient, low cost, cuttings transport system for offshore and onshore drilling installations. The screw conveyor are manufactured to the highest safety standards and are fitted with protective grating or cover to prevent foreign bodies entering the conveyor system, and to of fer enhanced safety for all personnel.

For more information about drilling waste management and Vertical Cutting Dyer,please contact GN Solids Control,we have exported to over 60 countries and regions.

Send product request

Other supplier products

| Decanter Centrifuge | GNLW Decanter Centrifuge GN Decanter Centrifuge is designed for the drilling mud solids control and oilfield waste management.GN VFD drive decante... | |

| Desilter | Mud Desilter GN desilter?is the third class?solids control equipment?to treat the drilling fluids. According to the size of the cone diameter, the... | |

| Desander | Mud Desander Following is desander for two different industry and system, Part 1 two desanders are for oil gas drilling, CBM drilling mud solids... | |

| Mud Cleaner | GNZJ Mud Cleaner GNZJ mud cleaner??is a normal model of our company,we can design?customized cost-effective?mud Cleaner for customers special need... | |

| Drilling Waste Management | GN Vertical Cutting Dryer is one of the popular products for OBM and SBM.As the developing for the evironment regulations,thedrilling waste managem... |

Same products

| 20' FT Open Top Container | Seller: Dong Fang International Containers | Open top containers are containers built for freight use, with a tarpaulin instead of a steel roo... | |

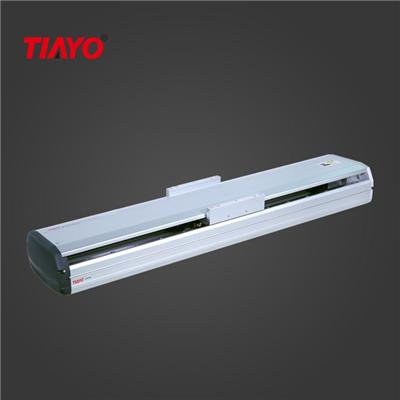

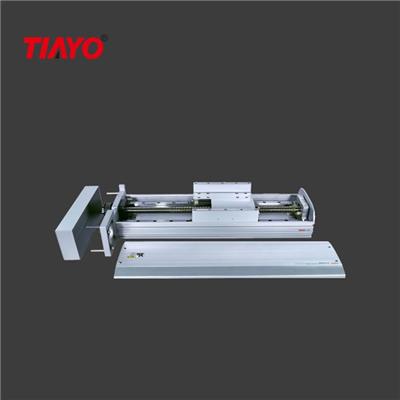

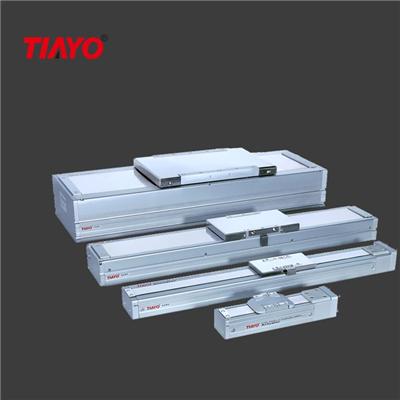

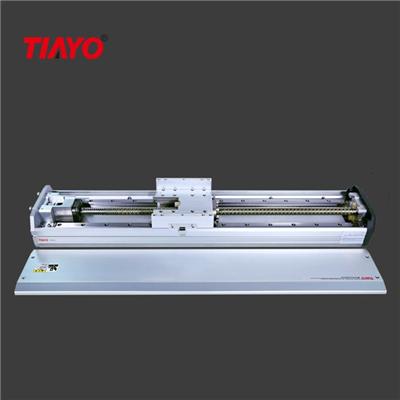

| Diy Ball Screw Linear Actuator | Seller: Hunan Tianyou Precision Technology Co.,Ltd | Diy Ball Screw Linear Actuator,Ball Screw Linear Actuator | |

| High Precision Ball Screw Linear Actuator | Seller: Hunan Tianyou Precision Technology Co.,Ltd | High Precision Ball Screw Linear Actuator,Website: Screw Linear Actuator | |

| Miniature Ball Screw Linear Actuator | Seller: Hunan Tianyou Precision Technology Co.,Ltd | Miniature Ball Screw Linear Actuator,Website: Screw Linear Actuator | |

| Linear Stage Actuator | Seller: Hunan Tianyou Precision Technology Co.,Ltd | Linear Stage Actuator,Website: Screw Linear Actuator |