cyclone dust collector for the lint collection at Fabric Rolling Machine

Introduction:

The CLP-B type cyclone dust collector can be used either alone or in combination with multiple cylinders. It is connected by a common gas inlet

and outlet gas cylinder to satisfy any smoke volume treatment. The unit of each dust collector has four parts: body, volute, core tube and sealed

dust collection device with good performance.

The working principle of the CLP-B cyclone dust collector after adding the bypass is that the dust-laden gas enters the tangential direction from

the entrance. When the air flow obtains the rotating motion, the air flow is separated from the upper and the lower to form a double-scroll

cochlear motion. The dust is in the double-scroll There is a strong separation effect at the boundary. The coarser dust particles are separated to

the outer wall with the down spiral vortex flow. Part of the dust is led out from the central hole of the bypass separation chamber, and the

remaining dust is carried by the downdraft. The upper vortex air flow has aggregating effect on fine-grained dust, thereby improving the dust

removal efficiency. This part of the finer dust particles, from the upper spiral vortex to the upper part, forms a strongly rotating upper dust ring

under the top cover, and enters the upper hole of the bypass separation chamber together with the upper spiral worm gas flow, and is introduced

into the cone through the return air inlet. With the internal air flow, the purified gas is discharged from the exhaust pipe, and the separated dust

enters the hopper.

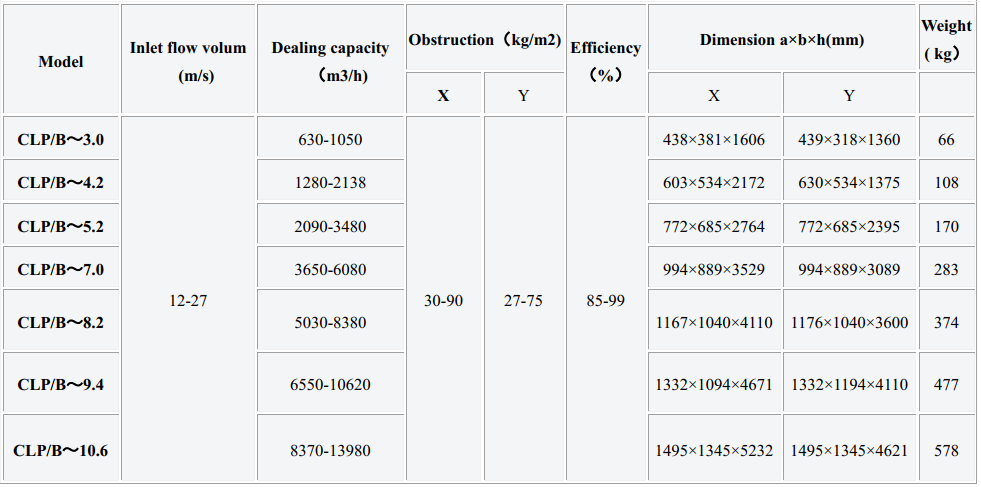

Structure size:

1. The size of the exhaust pipe The depth of the exhaust pipe should be at the interface between the upper and lower air swirlers. Exhaust pipe

insertion depth and dust removal efficiency. The depth of insertion is about 1/3 of the height of the intake day; and it has nothing to do with the

type of dust, the particle size distribution, and the inlet gas velocity. The deeper the insertion depth of the exhaust pipe, the greater the pressure

loss.

2. Bypass Separation Chamber Side Separation Separation The top side seam of the bypass chamber introduces the upper vortex gas flow into

the bypass separation chamber. The cone side seam introduces the dust ring formed by the lower spiral in the upper cone into the bypass

separation chamber. The height of the side seam is generally the distance from the top edge of the inlet to the top cover.

If you need, please feel free to contact Miss. Livia

Send product request

Other supplier products

| Air box pulse dust collector,Dust collecting system | Structure and working principle: Air box pulse bag filter dust collector is composed of shell (usually 5mm carbon steel plate welded), bracket and... | |

| LEFILTER lube oil filter UE219AS13H | LEFILTER lube oil filter UE219AS13H Introduction: 1.Lefilter filter is widely used in hydraulic system and lubrication system to filter out the m... | |

| 0 Tons Waste Tyre Pyrolysis Recycling Machine To Oil | Working principle:First, the raw materials are put into the reactor, and then seal the feeding in door, later start the machine and the reactor wil... | |

| Long bag pulse bag type industrial dust collector | Introduction: Long bag off-line pulse dust remover is mainly composed of upper tank, middle tank, ash hopper, air inlet flow pipe, bracket, filter... | |

| Cast Iron Basket Strainer DN150 | INTRODUCTION: Basket filter is piped to remove solid impurities in the process of the equipment. Liquid flow through the basket filter, then th... |