Stir Barrels

Application fields:Mineral processing and metallurgical and mining industries.

Materials:Placer gold, tin, tungsten, antimony, lead, zinc, manganese, diamond, iron ore and other.

Product advantage:

This computer in pharmaceutical and pulp before flotation operation full mix contacts, to maximize the pharmaceutical effect, it applies to not more than 30% and ore pulp and flotation of the density is less than 3.5 mixing.

1. Compact structure, good sealing, and feed port settings blocking grey Board,preventing water mist Gata;

2. Mix well, stirring blade fan, when mixing larger contact area with the media;

3. Nozzle row sets, water evenly and can be adjusted;

4. The low rate of ash left, watershed in the bottom of the box set to ensure that equipment without the dead angle

5. Mining advanced mixing drum performance, product quality is stable, uniform mixing, the material quickly.

Working principle:

1.At work, the machine is under the action of rotation of the impeller, pulp and chemicals, small circular movements, thus making the grooves of pulp, pharmaceutical to achieve uniform mixing, mixture of suspensions by the overflow port.

2.Stirring barrel is by electric motor v-belt driven impeller rotation, drugs and pulp adequate mixing to increase chemical reaction time necessary to strengthen drug-quality equipment, the machine applies to selected mining, can also be used for various chemical industry bad mix.Stirring barrel applicable to all kinds of metal ores, mainly used for flotation before mixing, are pharmaceutical and pulp adequate mixing, can also be used for other non-metallic mineral mix.It used to not more than 30% (by weight) fixture size is less than 1mm. it is in the form of flat-bottom bucket radiation circular helical impellers mechanical agitation. blender instructions for use before the first use of bolts fastening the pump body parts, rotate the pump shaft wheel is flexible, and then switched on, others with the flotation machine.

f3.Wearing parts: impeller, stator.

Specification: Model Slot size Effective volume Slot size Motor Weight

(kg)

Diameter

(mm) height (m3) diameter(mm) Rotating speed

(r/min) Model Power

(kw)

(mm)

XB-750 750 750 0.26 240 530 Y90S-4 1.1 550

XB-1000 1000 1000 0.58 240 530 Y90L-4 1.5 700

XB-1200 1200 1200 1.14 400 320 Y100L2-4 3 980

XB-1500 1500 1500 2.2 400 320 Y100L2-4 3 1330

XB-2000 2000 2000 5.46 550 230 Y132M2-6 5.5 2100

XB-2500 2500 2500 11.2 650 200 Y160L-6 11 3438

XB-3000 3000 3000 19.1 700 210 Y225S-8 18.5 5100

XB-3500 3500 3500 30 850 230 Y225-8 22 7900

Other supplier products

|

|

Powder Separator Series |

Application:

The machine is used in all materials powder screening process of mining, metallurgical, building materials industries.

Material: Gr... |

|

|

High Pressure Grinder Series |

Application: small and medium mine, chemical industry, building materials, metallurgy, refractory material, pharmacy, cement, etc.

Material: The m... |

|

|

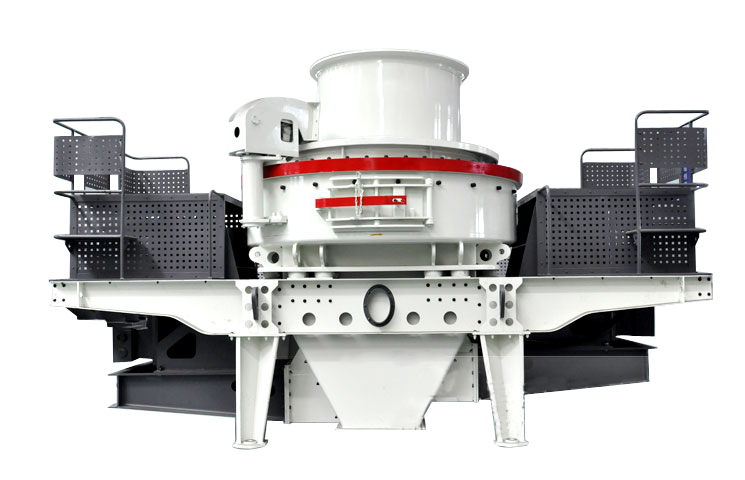

Sand Making Machine |

Application fields:Metal and nonmetal mines etc.

Materials:Iron ore, nonferrous metal ore, limestone, quartzite, sandstone etc.

Production Advant... |

|

|

Magnetic Separator Series |

Application fields:Mineral processing

Materials:Suitable for wet magnetic separation of pyrrhotite, roasting ore, ilmenite, and other materials ... |

|

|

Disc Polluter |

Application fields:it can be widely used in gold mining, chemical plant, construction and foundry for uniformly continuous, quantitative material... |

All supplier products

Same products