Rotary Dryer Series

Technical Advantage:

Equipped with Spreading plate, cylinder support the two roller by tyre, the gear wheel used to prevent the cylinder axial movement, thereducer drive big gear and small gear motor, and the big gear is fixed on the cylinder, the windshield prevent the cold air into thebody and the combustion chamber. Wet material with hot gas to feed the enter, in cylinder body lift up the lift plate material, makeit through the heat flow and drying. Our dryer can be made according to different drying materials for the external heating and withinheating. The external heating drying of charcoal, lees, coconut trees leather materials. In heating can be drying slime, sand, slag,chicken manure, cow dung and so on. Heat can use coal, gas occurrence furnace, hot air stove, gas, electric furnace.

Our dryer adopts new Spreading plate device, which has guidance, flow, material functions, it can make the material content in the dryer radial cross section to full uniform, material will become thin and all, the state of the heat flow entirely, to achieve the purpose of make full use of the heat.Our dryer choose reasonable operating parameters, coal consumption and power consumption of general baked dry machine more than 10-15%, one machine yields above 10-15%, it has been widely used. in the cement and mineral processing enterprise.

Operating principle:

Dryer heat from the combustion device, the dryer adopts whatever in heating mode. Therefore need to dry the material from feeding, the feeding slipped into the cylinder, it is spiral copy board.On the one hand the dryer tilt put material on the gravity and return flows back end, on the other hand the material being copy board over and over again, brought to the top and lift it down constantly, make the material inside the tube forming uniform curtain, and the heat flow into the line of heat exchange in the cylinder fully, because of the material and Spreading plate, contains the moisture of being drying, thus attaining the purpose of drying.

SpecificationModel (m) Capacity(t/h) Main motor Main engine rate Weight(T)

Power (KW) Model Model speed ratio

Φ1.2×10m 2.5 7.5 Y160M-R3 Zl50-16-I -- 13.5

Φ1.5×12m 3.3-4.9 10 Y160L-6-B3 JZQ500-III-2F -- 18.9

Φ1.5×15m 4-6 18.5 Y200L1-6 JZQ500-III-2F -- 21

Φ1.8×12m 4-6 18.5 Y160L-6 ZQ50-16II-2 16.46 23

Φ2.2×12m 7.12 18.5 Y200L7-6 JZQ650-III 31.5 38

Φ2.2×14m 7.12 22 Y200L7-6 JZQ650-III 31.5 40

Φ2.2×16m 12 30 Y225M-6 JZQ750-III 31.5 45

Φ2.4×14m 12 30 Y250M-6 JZQ750-III 31.5 51

Φ2.4×18m 10-13 37 Y250M-6 ZL85-13-I 27.16 54

Φ2.4×20m 10-14 37 Y250M-6 ZL85-13-I 27.16 55

Φ3×20m 25 55 Y250M-4 ZL100-16-I 41.52 78

Φ3×25m 32-36 75 YR280M-4 ZL100-16-I 41.52 105

Other supplier products

|

|

Powder Separator Series |

Application:

The machine is used in all materials powder screening process of mining, metallurgical, building materials industries.

Material: Gr... |

|

|

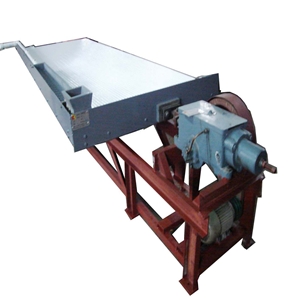

Shaker |

Application fields:Mineral processing

Materials:It is widely used in the tin,wolfram,gold,and silver, lead, zinc, tungsten, tantalum, niobium,ti... |

|

|

Compound Cone Crusher |

Application fields:Widely used in mining ore crushing, broken broken rocks with high hardness materials, building materials, cement, aggregates,... |

|

|

High Pressure Grinder Series |

Application: small and medium mine, chemical industry, building materials, metallurgy, refractory material, pharmacy, cement, etc.

Material: The m... |

|

|

Efficient Enrichment Machine Series |

Application field:Non-ferrous metal ore pulp

Product Advantage:

1、Add flocculant increased size of solid particles settlement, thus speeding up... |

All supplier products

Same products