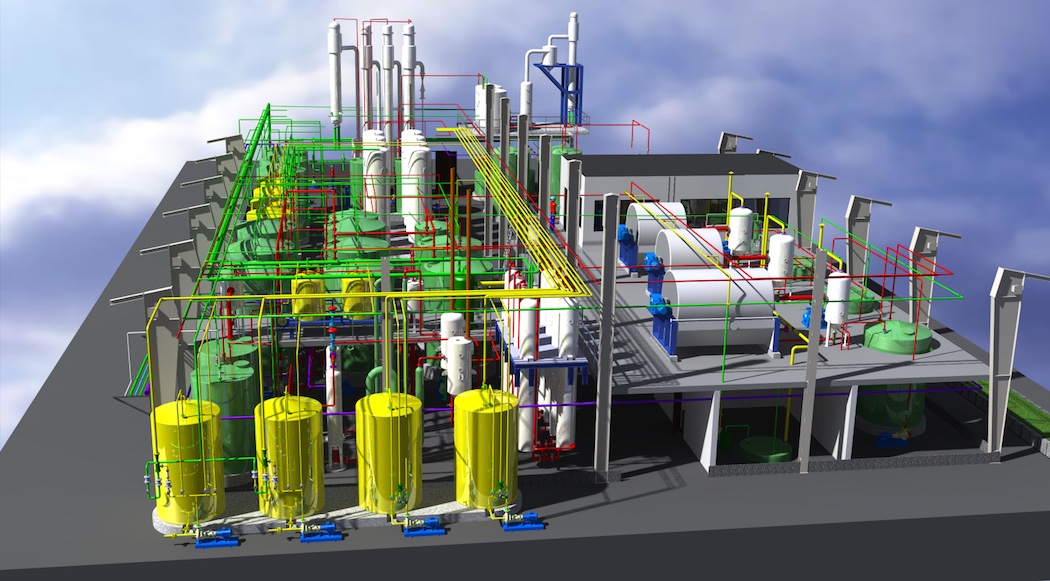

fructose design/processing production line/project/engineering

Dextrose is enzymatically isomerized to fructose by passing through isomerization column.

(1) Preparation:

To facilitate isomerization of dextrose to a 42% fructose solution, salts such as BSS, Na2CO3, MgSO4 are added back to the syrup though demineralization of dextrose syrup have been finished before dextrose evaporator.

(2) Isomerization:

The dextrose syrup goes though the isomerase enzyme column where convert dextrose to fructose, under conventional conditions, it is generally produces a syrup containing a minimum of 42% fructose.

(3) Decolorization:

Carbon (granula or powder) or adsorbent resins remove color, flavor and odor compounds from 42% fructose syrup, generally, carbon is often used ahead of ion exchange whereas adsorbent resins are used after ion exchange.

(4) Demineralization:

The salts which are added back to facilitate isomerase enzyme performance must be removed after isomerization via demineralization to produce a pure sweetener for sale or subsequent enrichment to a 55% fructose solution.

(5) Evaporation

Dilute 42% fructose syrup is concentrated to solid 70.5%~71.5% by evaporation of water.

HFCS 55 Process description

Separating the F42 by chromatography can obtain high fructose glucose syrup (HFGS). Mixing the HFGS and F42 in a certain proportion can produce F55.

(1) Chromatographic separation: Transport 50% F42 to Chromatographic separation column, run according to the specific procedure, glucose and fructose will be separated, F90 fructose-glucose syrup can be obtained.

(2) Mixing: Mixing F42 and F90 in a certain proportion to produce F55.

(3) Decolorization: The F55 needs to be purified by decolorization.

(4) Mixed bed: The decolorized F55 needs to be purified to remove the salt and other impurities by mixed bed, so as to guarantee the quality of final product.

(5) Sterilization: Use special filter to remove bacteria from F55 product, so that the product can meet the standard requirement.

(6) Evaporation: After sterilization, use evaporation to increase the concentrate of F55 product.

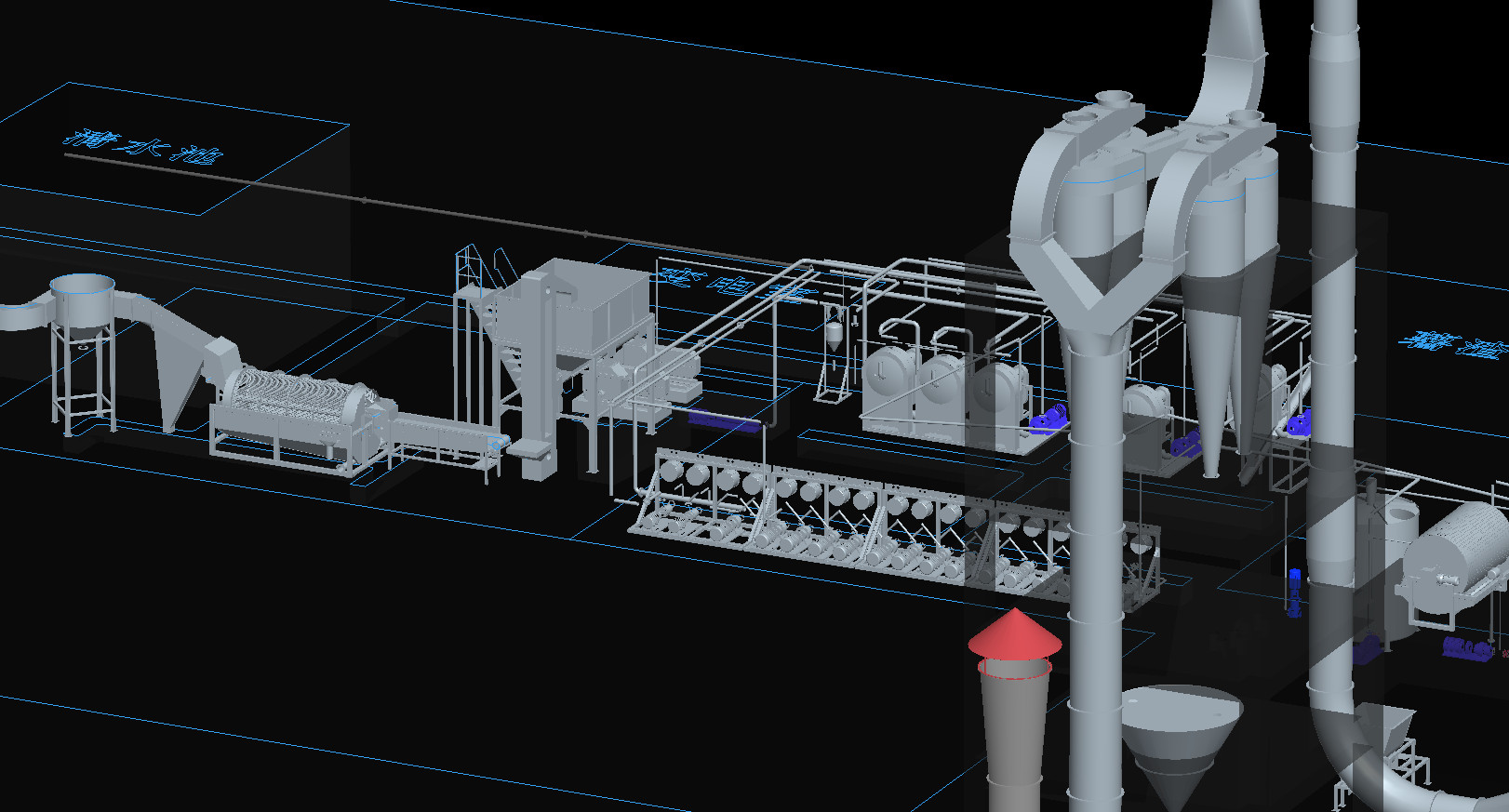

Pure Crystalline Fructose (PCF) Process description

In the production of 55% fructose from 42% fructose, an economical limit of 42%~44% fructose syrup is achieved by using isomerase enzyme, to obtain a higher purity fructose solution such as 55% fructose, it is necessary to produce fructose-rich fraction and dextrose-rich fraction which is accomplished via SSMB. generally, 55% fructose is obtained by blending 42% fructose syrup with 90% fructose syrup.

(1) Chromatographic separation

Owing to a greater of number of sites available for hydrogen bonding, the fructose molecule will form a coordination complex with calcium ions fixed onto a strong acid cation resin. which results different affinity of the resin for fructose molecule and dextrose molecule. hence it is separated after they pass though the resin bed. normally, a production purity of 90% fructose can be achieved at a 90% recovery.

(2) Blending

The fructose-rich fraction can be blended with 42%~44% fructose to obtain 55% solution.

(3) Polishing

It contains ppm quantities of impurities such as color, odor, protein, HMF, and residual ash in 55%fructose solution, In order to produce a heat stable product of high quality, the syrup can be polished by the mixed bed of hydrogen from strong acid cation resin and hydroxide form strong base anion resin.

(4) Evaporation

Dilute 55% fructose syrup is concentrated to solid 76.5%~77.5%by evaporation of water.

Other supplier products

All supplier products

Same products