Biofuel Rice Husk Pellet Line

Brife Introduction of pellet Making line

A complete pellet line capacity is fromsmaller 500kg/h to bigger 30ton/h.

Until now hundreds of pellet production lines are installed in China and abroad, such as France, Bulgaria, Romania, Hungary, Argentina, Belarus, Japan, Korea, India, Indonesia, Vietnam, Malaysia, Thailand, Laos, ect . Greatly welcome to visit our factory.

|

Requirements for raw materials |

|||

|

Size

|

Less than 5 mm

|

All the raw materials must be crushed into sawdust before going to wood pellet mill.If not, you may need a wood chipper, wood crusher. |

|

|

Moisture

|

10-15%

|

Better for pelletizing high quality pellets,

|

|

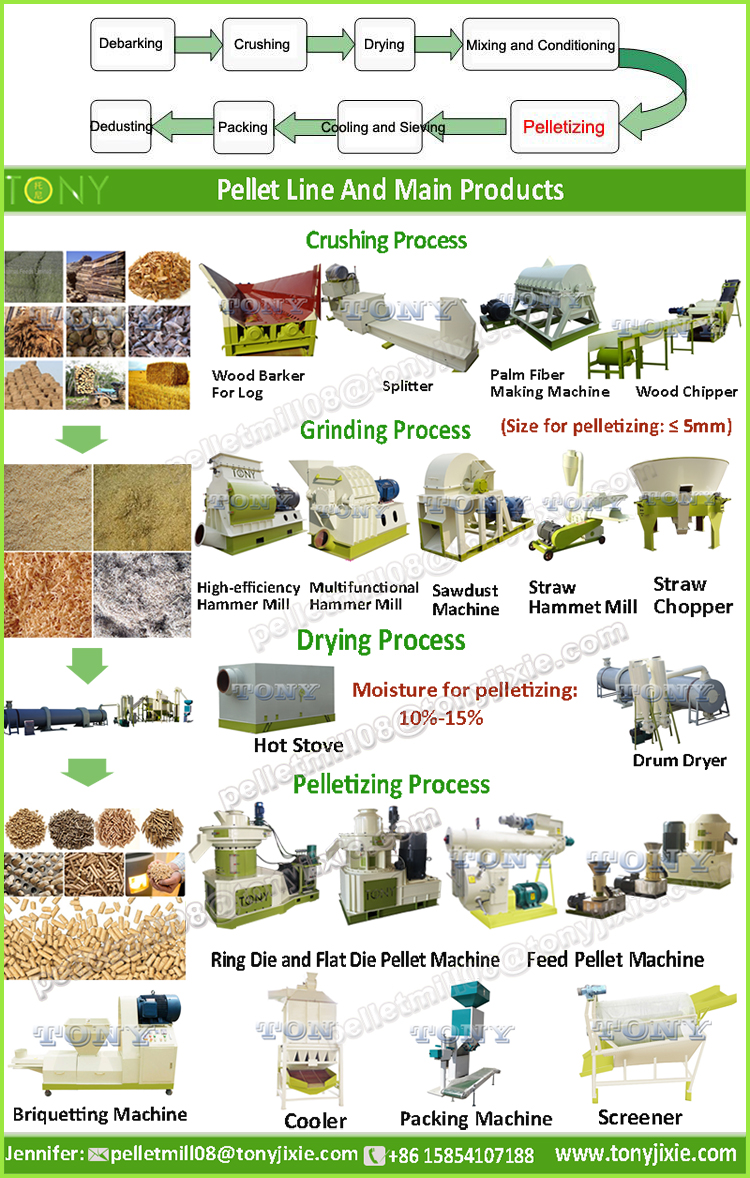

A Complete Wood Pellet Linemainly processes includes:

Crushing----- grinding --- drying ----- pelleting ----- cooling ----- packing

Detailed explanation for complete biomass pellet line

| Step | Product name | TechnicalParameter | Main machinesIncluded |

| 1 | Raw material | *If you need to bare a tree of its bark, from 2 step; *If logs or other large size materials, from 3 step, be splited into wood chips *If small pieces, directly from 5 to reduce the size suitable for pelleting |

/ |

| 2 | Barking process | For making high quality pellets(optional) | Debarker machine |

| 3 | Crushing process | Raw materials (size: thickness >10mm and L * W >50 * 50mm), are crushed or shreddered into chips or small size. | 1.Log splitter 2.Sawdust Chipper 3. Drum Chipper 4.Mobile Branches Grinder 5.Chaffer Cutter 6.Palm Fiber Making Machine |

| 4 | Dryer (withhotstove) |

Rotary Dryer includes Stove and Main Rotary Dryer, which can reduce the moisture from 50% to 10%. Our stove is fueled by coal and biomass fuel, saving electrical energy largely. (client can build the hot stove by self, and we provide its drawing) The moisture content of raw materials must be controlled :10%-15%. |

1.Rotary Drum Dryer 2. Air Flow Dryer |

| 5 | Grinding process | The chips or small size raw material are ground by hammer mill to particle size less than 5mm suitable for pelleting. | 1.High efficiency Hammer mills 2.Multifunctional hammer mills 3.Wood Crusher 4.Straw Hammer Mill 5.Straw Rotary Chopper |

| 6 | Pelleting process | Pellet mill machine is the most important equipment : Pressrawmaterialintopellet. | 1.TYJ series Ring Die pellet mills 2.Skj series Flat Die pellet Milll |

| 7 | CoolerSeparator | Completeclosedstructure,stainlesssieve, lownoiseandstableoperating |

CoolerSeparator |

| 8 | Transport modules between the components | Elevating Conveyor, belt conveyor, screw conveyer | |

| 9 | Pulseddust collector |

collectingdust, cleanthepellet. | Pulseddust collector |

| 10 | PackingMachine | In this process, we suggest our Semi-Auto Packing Machine to you. Theweightingscopeofthismachineis15kg-50kg perbag. |

1.Ton Packing Machine 2.Automatic Packing Machine 3.wood Shavings Bales |

Seccessful Export Experience(Client's Site)

Our products have been exported to lots of Europe, South America, Southeast Asia countries, and set agents in Brasil ,Canada, Germany, America, South Africa, Australia, India,Vetnam, Malaysia, Croatia, Serbia and so on.

Quality Guarantee:

----The electrical motor, gear box and electrical cabinet is 1 year; The upper body and box of main shaft is 1 years(except wearing parts).

----Wearing parts just like die and rollers is 2000 working hour.

----Any losses which are caused by operation mistakes, man-made problems, etc will be responsible for clients-self.

ABOUT US

|

ZhangqiuTONYMade Machinery Co.,Ltd --- Professional Manufacturer of Pellet Machines |

|||

|

Brief Intro

|

Owns a professional team in researching, designing, manufacturing, trading, installing instructing and serving on pelleting equipments.

|

||

|

Address

|

Zhangqiu,Jinan City,Northe China.We enejoty convenient water,land,railway and air transportation.

|

||

|

Successful Export Experiences

|

"TONY" machines with good reputation have been exported to lots of Europe, South America, Southeast Asia countries, and set agents in Brasil ,Canada, America, South Africa, Australia, India,Vetnam, Malaysia and so on countries.

|

||

We mainly manufacture the following equipments for the pellet line

1.TheSKJ Series flat die pellet millwith the volume 100kg per hour to 4 ton per hour.

2.TheTYJ Series ring die pellet millwith the volume 800kg per hour to 5 ton per hour.

3.TheSKJD Series Pellet Millwith Diesel Engine with the volume 100kg per hour to 400kg per hour.

4.The SKJT Series Pellet Millwith Tractor Engine with the volume 80kg per hour to 400kg per hour.

5.Hammer Mill

6.Wood crusher

7.Wood chipper

8.Drum dryer

9.Packing machine

10.Whole pellet making production linefrom the volume 0.5 ton per hour to 20 ton per hour.

Best Servive

Pre-sale service:

Provide customers the paramenters and confirm technical points.

Share photos and videos with clients.

Show our factory to clients for checking.

On-purchase service:

Keep clients informed of the production progress.

Send photoe to clients before shipments for checking.

Arrange the visa for engineers who will go for guiding assembly.

After-sale service:

Training and all-around technical guidance for operation commission and maintenance.

Engineers avaliable abroad to guide assembly.

Are you confusing as following questiones?

Q: This is my first time to import, how can I trust your company and ensure to get the goods if I order from you?

A: We are alibaba legitimate certification company (VIP), and we support payment terms: L/C.T/T.

Q: There are too many models, i don't know which one to choose.

A: Welcome to contact us through TradeManager,we will recommend according to your requirement. If during closing time or weekend,Please send mail to us,we will response within 24 hours.

Q: How to ensure that I received the machine undamaged?

A: At first , our package is standard for shipping, before sign in, please cfm product undamage, otherwse, pls contact with us within 2days, we've bought insurance for you, we or shipping company will be responsible!

Terms of Payment: 35% payment by T/T as deposit in advance, balance payment after inspection before shipping.

Delivery Time: 20-45 days after receipt of the 35% deposit from the buyer

Contact Information

MS.Jennifer Zhao

Email: /> />Tel: 0086-531- 83698878

Factory: Zhangqiu Tony Made Machinery Co., Ltd.

Send product request

Other supplier products

| Palm Fiber Pellet Production Machine Line | Biomass Wood Pellet Line Brife Introduction of pellet Making line A complete pellet line capacity is fromsmaller 500kg/h to bigger 30ton/h.Until ... | |

| Biofuel Rice Husk Pellet Line | Biomass Wood Pellet Line Brife Introduction of pellet Making line A complete pellet line capacity is fromsmaller 500kg/h to bigger 30ton/h.Until ... | |

| Biofuel Sawdust Pellet Mill | Function of Vertical Ring Die Wood/Feed Pellet Machine Pellet mill machine is also named as pellet mill/pellet press/granulator/pelletizer. It... | |

| 1t/h 2t/h Straw/Wood Complete Pellet Production Line | Biomass Wood Pellet Line Brife Introduction of pellet Making line A complete pellet line capacity is fromsmaller 500kg/h to bigger 30ton/h.Until no... | |

| Wheat Bran Straw Complete Pellet Line | Biomass Wood Pellet Line Brife Introduction of pellet Making line A complete pellet line capacity is fromsmaller 500kg/h to bigger 30ton/h.Until no... |

Same products

| China High Quality Sliding Table Saw For Woodworking | Seller: QINGDAO UNITED ASIA INDUSTRY CO.,LTD | Model No:UA3200SDimension of sliding table saw 3200*375mmGross cut capacity 3200mmWidth of cut be... | |

| Concrete Cutting Diamond Wire Saw Rope | Seller: Xiamen ChinShine Industry and Trade Corporation | Concrete cutting diamond wire saw rope has become an important tool in the field of concrete cutt... | |

| Electric Pruning Shears | Seller: Zhejiang GuYueHu Industry&Trade Co.,Ltd. | Electric pruning shears, also called electric cutting shears or electric garden shears use rechar... | |

| Solar Cells | Seller: Sunrise Energy Co., Ltd | Solar Cells The solar cell qualitycan directly convert light energy into electrical energy throu... | |

| New F800 Saw Table With Electric Saw For Woodworking | Seller: Guangzhou Yamu Paile Industrial Co., Ltd | Specially designed for the opening plate, which can be customized by pushing left and right F8... |