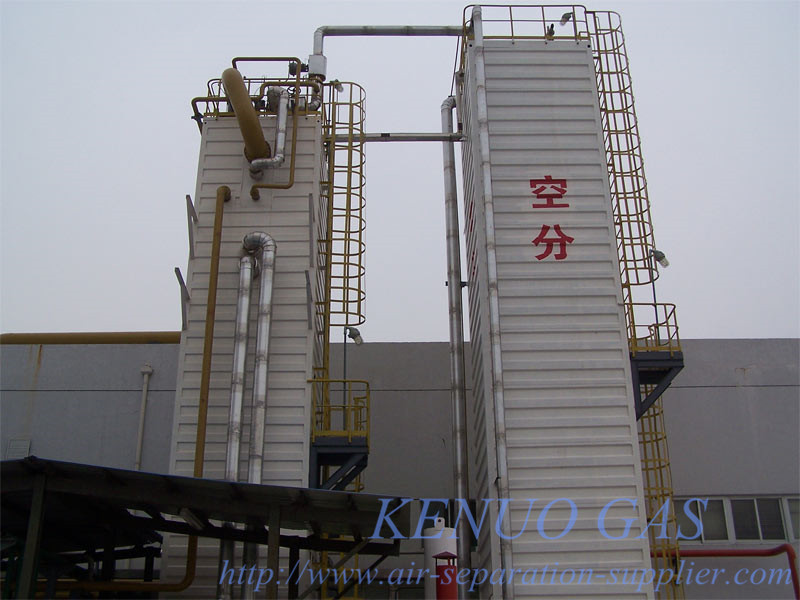

Cryogenic Air Separation Nitrogen Generator

Air which was sucked in from air intake tower enters the suction air filter and after being removed of dust and other mechanical contaminants in it, it is compressed to the pressure of 1.0MPa by piston air compressor. Air from the air compressor is cooled to ~5C in the refrigeration unit, taken into the molecular sieve adsorber for removing H2O, C2H2 and CO2. There are two molecular sieve adsorbers which operate on a staggered cycle, i.e. one vessel is adsorbing the contained impurities while the other is being reactivated by waste nitrogen from the rectifying column.

Then the cleaned air is taken into the rectifying column and cooled by the return waste nitrogen, oxygen and nitrogen through the main heat exchanger. The steam-liquid air mixture is taken into the lower column for rectifying, and herein the pure nitrogen of 99.99% from the top of the column enters into the evaporator-condenser and condensed by liquid air from the lower column. A part of the liquid nitrogen is fed to the lower column as reflux.

In the main evaporator-condenser, liquid air is evaporated to steam, then enters the main heat exchanger and get out from the middle of the main heat exchanger and enter into the turbine expansion to generate most refrigeration for need of the plant's operation. After the expander, air enters to the main heat exchanger, and get out from the cool box.

The product nitrogen of 99.99%N2 gained at the top of the lower column is warmed up through the main heat exchanger and then taken to the user.

The waste nitrogen from the cold box is divide into two parts, one part goes to the regeneration molecular sieve adsorber system and the other part is vent.

Other supplier products

|

|

Cryogenic Air Separation Nitrogen Generator |

Air which was sucked in from air intake tower enters the suction air filter and after being removed of dust and other mechanical contaminants in it... |

|

|

Molecular Sieve 5A |

Kenuo’s molecular sieve 5A can adsorb any molecule with aperture <5A and is widely used for hydrocarbon separation, PSA and coadsorption. Spe... |

|

|

Movable Motor Drive Screw Air Compressor |

Increasing gas pressure according to individual requirement

Working process: Increasing gas pressure in the cylinder by piston motion |

|

|

Cryogenic Liquid Vacuum Storage Tank |

Liquid oxygen storage tankFeatures:1、Adopting two-way inlet system.2、Simple, compact and orderly layout.3、Using duplexed safety valves and explosio... |

|

|

VPSA Oxygen Generator |

Features:1、Large oxygen output, low energy consumption. Adjustable oxygen purity between 25%-95%.2、Low maintenance cost, blowing machine and vacuum... |

All supplier products

Same products