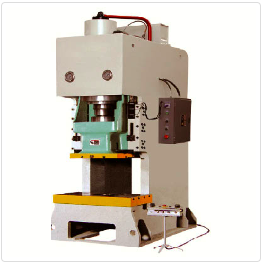

Die forging hydraulic press

1.Product description

AYD16 series die forging hydraulic press is a modern die forging high-precision forming equipment produced by introducing advanced technology from the world, which has a wide range of applications, including multi-directional extrusion, upsetting, punching, closed die forging and so on. It is mainly suitable for forging production of all kinds of extra-long forgings, shafts, discs and special-shaped parts, such as bearing inner rings, flanges, half shafts, joints, crossheads, hubs, train wheels, etc.

2.Features and advantages

-

The equipment adopts prestressed composite frame structure or integral frame structure, with stable and reliable structure, long servie life and working tonnage up to 30,000 tons;

-

One piece of equipment can be equipped with multi-stations according to the technological requirements, and forging can be carried out in one step, with high production efficiency and low production cost;

-

Forming has two working modes: fixed size pressing and fixed forming force pressing, which can be selected at will;

-

Auxiliary systems such as servo energy-saving system, quick mold change system, automatic mold spraying and lubrication system and automatic feeding system can be configured.

3.Application

This series of hydraulic press is suitable for stretching, bending, flanging, cold extrusion, blanking and other processes of metal materials, as well as for correcting, pressing, pressing and forming powder products and abrasive products, and pressing and salting plastic products and insulating materials. It is widely used in large, medium and small enterprises, factories, industrial and mining and automobile repair shops, heavy machinery, flange plates, belt pulleys, shaft bushings, disassembly and assembly of bearings, straightening and correction, bending, punching with dies, blanking, stretching and flanging instead of the old screw hand press for forming, and jack testing with pressure gauges.

4. Product model:

Die forging hydraulic press is also called: hot die forging, liquid die forging and multi-direction die forging. The tonnage of die forging equipment of our company is 2500, 4000, 5000, 6300, 10000 tons hot die forging, aluminum wheel forging and other models.

Send product request

Other supplier products

| C type open Hydraulic stamping punching machine | 1.Product description C type open Hydraulic stamping punching machine combines the advantages of punch press and single-column hydraulic press. It... | |

| JX36 Closed Type Double Points Press | FEATURES: The steel sheet welding structures, upper cross beam, upright and pedestal form the closed structure by pretightened with the tension bo... | |

| JS36 Striaght Side Double Points Press | JS36 Striaght Side Double Points Press is suitable for applying in heavy tonnage die tooling with different precision in blanking, piercing, bendin... | |

| High performance Frame hydraulic press | 1. Description Frame hydraulic press is used for various stamping processes of metal materials, such as drawing, blanking (blanking buffer device ... | |

| single-column hydraulic press machine | Based on the advanced hydraulic manufacturing industry, our company is committed to the design and manufacture of all kinds of hydraulic mechanical... |

Same products

| Blanket Flammability Test Machine | Seller: Standard Groups | Bed Blanket Flammability Tester-It is mainly used for testing the flame retardant performance of ... | |

| High Temperature Oxygen Index Tester | Seller: Standard Groups | The High-Temperature Oxygen Index (TOI) measuring instrument determines oxygen index at up to 125... | |

| Limiting Oxygen Index Tester | Seller: Standard Groups | The Limiting Oxygen Index Tester measures the minimum oxygen concentration needed to sustain comb... | |

| Vertical Flammability Tester | Seller: Standard Groups | Vertical Flammability Chamber for measuring the vertical flame spread for children’ sleepwe... | |

| 45 Degree Flammability Tester | Seller: Standard Groups | Application 45 Degree Flammability Tester is used to determine the burning characteristics of te... |