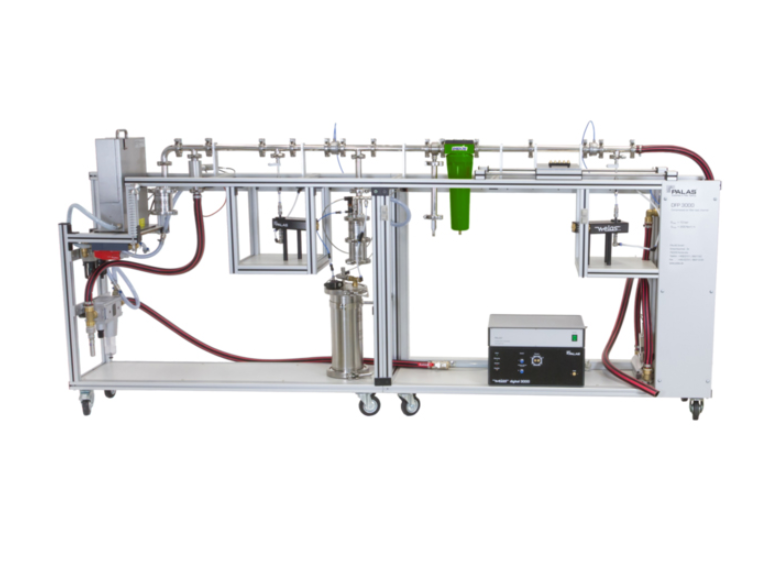

Oil mist separation efficiency test bench

Quality assurance and the development of filters/separators/collectors should ideally be conducted under test conditions relevant to the actual conditions encountered. Therefore, oil separators must be tested at high temperatures up to 120°C and, depending on the application type, at high pressures.

Using the modular test system HMT 1000. oil separators (e.g., for separating leaked aerosols in internal combustion engines or for separating oil mist downstream of compressors) can be characterized quickly and accurately, and successfully tested under real-world conditions via isothermal particle measurements up to 120°C:

• Staged separation efficiency

• Load/holding time

• Total separation efficiency/weight analysis

• Pressure loss

Due to the modular layout, individual components of the test bench, such as the high-resolution heated light scattering spectrometer, the heated dilution system KHG 10 D, and the heated aerosol generator PLG 2100. can be easily removed from the HMT 1000 and used for other applications, such as direct measurements on the engine.

At the heart of the HMT 1000 is the light scattering spectrometer, which is used to simultaneously and independently measure particle size and particle number (and thus concentration). With the Promo® 1000 H, very fast, clear, reproducible, and isothermal measurements are possible.

Standard

GB/T 6165-2021

Technical parameters

| Measurement range (size) | 0.18 – 40 µm |

| Volume flow rate | 1 – 25 Nm3/h, 1 – 85 Nm3/h (Other specifications available upon request) |

| External dimensions | Approximately 1.600•2.000•800 mm (H•W•D) |

| Differential pressure measurement | 0 – 5.000 Pa (ande auf Anfrage) |

| Aerosol concentration | Up to 107 particles/cm3. equipped with 2 KHG 10 D |

| Compressed air supply | 6 – 8 bar |

Send product request

Other supplier products

| Compressed air filter test bench | The Compressed Air Filter Test Bench is a fully automated system designed to measure the fractionation efficiency of compressed air filters at over... | |

| Gas Jet Erosion Rig | Standard Performance The velocity of the particles is determined by the air pressure and length of nozzle. A wide range of velocities is covered f... | |

| Textile Drying Time Tester | TheTextile Drying Time Testeris a precision instrument designed to measure the evaporation rate and drying time of textiles under controlled enviro... | |

| Wet leakage current test system of photovoltaic module | The Wet Leakage Current Test System is designed for high-precision evaluation of insulation resistance and leakage current in photovoltaic modules ... | |

| wyzenbeek/Oscillatory Abrasion Tester - Test Equipment | Wyzenbeek wear resistance tester, also known as Oscillatory wear resistance tester, is used to test the wear resistance of fabrics against standard... |

Same products

| Filter cartridge pore size tester | Seller: Standard Groups | This instrument is widely used in fields such as determining the effective pore size of geotextil... | |

| Filter Dynamic Cycling Tester | Seller: Standard Groups | Filter element dynamic cycling test bench is mainly used to test the chemical element precipitati... | |

| Steam Jet Test Chamber,anti-corrosion steam spray testing chamber | Seller: Standard International Group (HK) Limited | The Steam Jet Test Chamber is designed to evaluate the durability and performance of materials an... | |

| Filter Flow Resistance Test Bench | Seller: Standard Groups | The Filter Flow Resistance Test Bench is designed to evaluate the differential pressure character... | |

| Comprehensive Engine Oil Filter Test Bench | Seller: Standard Groups | This test bench is designed for comprehensive evaluation of engine oil filters, including spin-on... |