Shale Shaker

Model

GNZS752E-DM

GNZS703E-HB

GNZS703E-DZ

GNZS594E-HB

GNZS594HGE-LD

Vibration Mode

Linear Motion

Capacity(m³/h)

45(200GPM)

120(528GPM)

140(616GPM)

Vibration Motor(Kw)

2×0.75

2×1.72

2×1.94

Angle Adjust Motor(Kw)

N/A

0.55

Screen Qty(Pcs)

2

3

4

Screen Size: L×W(mm)

750×900

700×1250

585×1165

Screen Area(m2)

1.35

2.63

2.73

Adjustable G Force

≤7.1G

≤7.5G

≤8.0G

Vibration Amplitude(mm)

3.92 ~ 5.62

4.14 ~ 5.96

4.4 ~ 6.34

Deck Angle Range

+2°

-1 ~ +5°

Feeding Type

Box Feeder

Weir Feeder

Box Feeder

Weir Feeder

Hopper Feeder

Weir Height(mm)

710

895

1042

895

EX Standard

ExdIIBt4/IECEX/A-TEX

Weight(Kg)

893

1633

1699

1680

1618

Dimension: L×W×H(mm)

1676×1689×1062

2717×2058×1428

2419×2098×1474

2937×2058×1428

2761×2058×1428

Remarks:

Low Weir Feeding Shaker GNZS703ED-HD, weir height 625mm is available for option.

Key Features

● Adjustable High G Force up to 7.5 G.

● Mechanical shaker deck angle adjustable while working

● Patent tighten rubber sealing for shaker deck and screen, long life and easy replacement.

● Shaker bottom deck made from Stainless Steel for long service life.

● Heat treatment on complete shaker deck for High G force operation.

● Pretensioned Shaker screen for fast screen replacement.

● Famous Brand Vibration Motors : IEC Ex, ATEX and UL Certified

● Electrical components: SIEMENS, Schneider Brand

● Flexible feeding type including Weir Feed, Top Feed, and Hopper Feed for different applications.

Other supplier products

|

|

Shale Shaker |

Model GNZS752E-DM GNZS703E-HB GNZS703E-DZ GNZS594E-HB GNZS594HGE-LD Vibration Mode Linear Motion Capacity(m³/h) 45(200GPM) 120(528GPM) 140(616... |

|

|

Flare Igniter |

Model GNYD200A Main body Diameter(Inch) 8 Charging Power 100V-240V ~ 50/60Hz Ignition Voltage(Kv) 16 Ignition Media LPG Weight(Kg) 520 Dimension: L... |

|

|

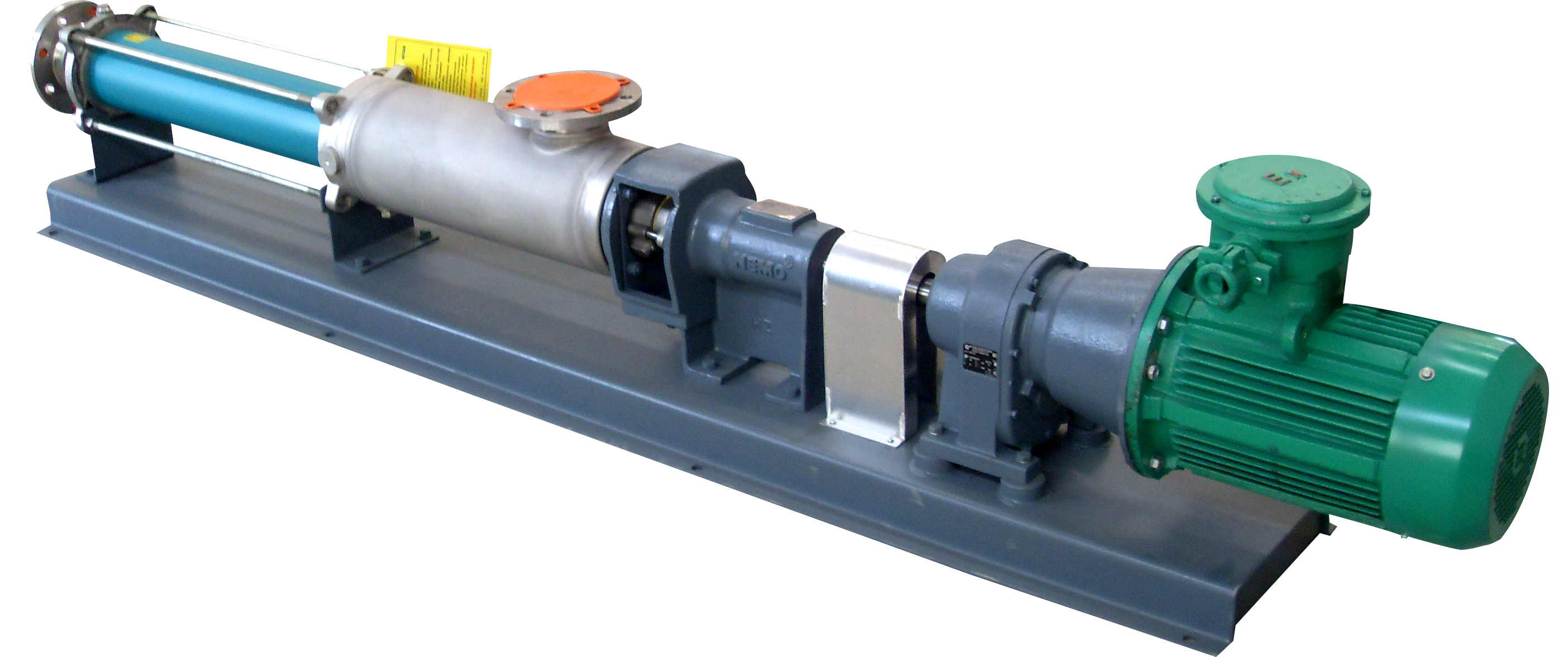

Screw Pump |

Key Features The GNG Series Positive Displacement Pump is a single screw pump .The pump is an ideal pump for feeding to decanter centrifuge without... |

|

|

Mud Gas Separator |

Key Features GN Mud Gas Separator is designed for continuous drilling in underbalanced conditions where dramatic pressure surges are normal. The GN... |

|

|

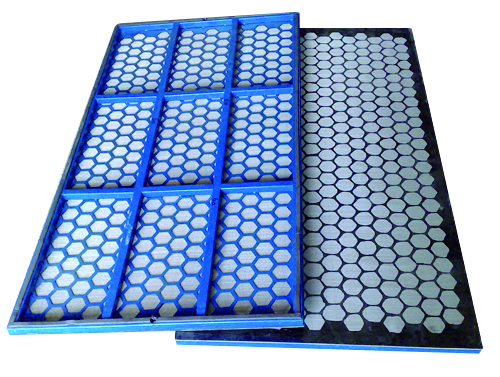

Shale Shaker Screen |

GN adopt the international most advanced technology to manufacture all kinds of shale shaker screens.GN also supply replaceable screens for all the... |

All supplier products

Same products