Panel Bender

Panel Bender

As one of the panel bendermanufacturers in China, Remcor panel bender for salecan realize automatic bending, compared with a traditional press brake, it is much more labor cnc panel bendercost saving and higher efficiency. This automatic panel bender support the positive, and negative bending, any angles from 0-180 degree bending, folding, etc. Panel bender sheet metal coil line is widely applied in steel furniture, electrical cabinet, etc.

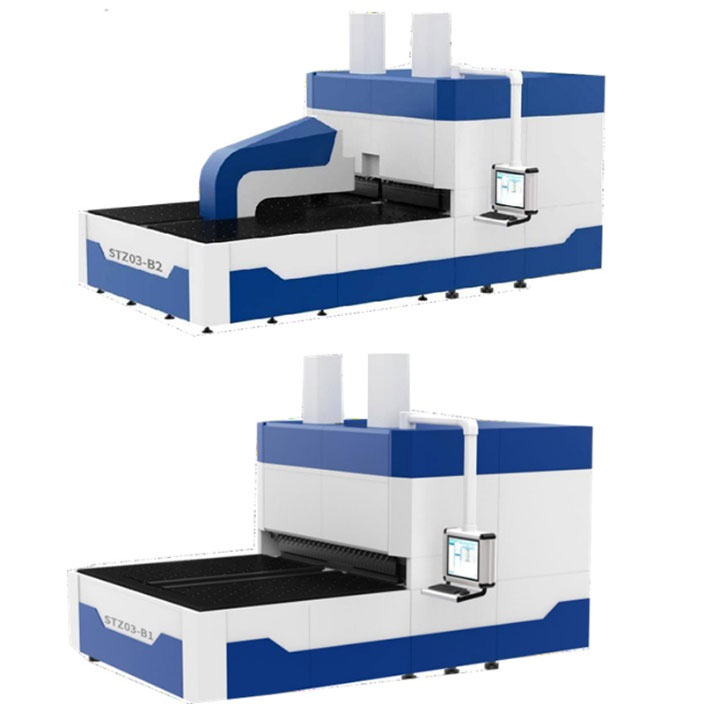

- Panel Bending MachineAppearance

panel bending machine

The intelligent flexible bending center is a high-tech product developed and produced for the sheet metal industry to improve production efficiency, reduce labor intensity, reduce labor costs, and enhance corporate image. It has been widely used in various industries such as filing cabinets, electrical cabinets, door industry, tool cabinets, kitchen utensils, ventilation, air conditioning, elevator industry, purification, education and experimental equipment.

panel bender for sale

High productivity. The fastest continuous bending speed can be 0.5S and can realize the automatic and continuous bending. The cycle time saving up to 60% compared to the die bending.

Flexible and high automatic processing. Flexible bending multiple sides, less re-tooling time. Labor cost saving at 4-5 times compared with traditional press brake.

Precise bending. The very first step manual positioning and imported servo motor control the bending process precisely.

Simple operation. Clear and simple windows, the operator can handle the bending process in a easier way.

The intelligent bending center can realize complex shapes such as bending right angles, non-right angles, circular arcs, upper and lower pressing dead edges, etc., and is used in the metal forming field of different workpieces in different industries; the equipment adopts all-electric servo motors instead of hydraulic drives, which is environmentally friendly, fast speed, high precision, maintenance-free and other advantages.

There are two types of casting parts and steel plate welding parts for the equipment body, which can meet the needs of different processes, products and users.

The cast fuselage frame undergoes precise finite element force analysis, adopts the most stable circular radial triangle interconnection design, and selects high-grade QT500-7 and HT250 or higher castings after strict material analysis.

The welding fuselage is made of Q235 high-quality steel plate, which is welded on a special platform after advanced welding technology, which ensures the welding accuracy of the fuselage; This greatly ensures the overall stability of the fuselage under high tonnage force.

Both fuselages are subjected to a high-temperature annealing process according to the temperature curve corresponding to the material and are subjected to large-scale.

The shot blasting machine is cleaned of sand, and the bed's surface is clean. Castings and welded parts are subjected to open-air aging treatment after rough machining. Thoroughly release the internal stress before doing fine processing to ensure that it will not deform for a long time and ensure the stability of the complete accuracy.

The bending tool is made of 42CrMo forging material, which is made through strict roughing, finishing and other processes, as well as heat treatment, quenching and tempering, laser quenching and other processes, ensuring the service life of the tool and bending requirements. Different straight knives, scimitars, large scimitars, upper and lower pressure knife avoidance, hinge knife pneumatic, electric control and other knives can be designed and customized according to the user's workpiece, and auxiliary bending knives can also be installed for complex bending processes to maximize to meet various bending needs.

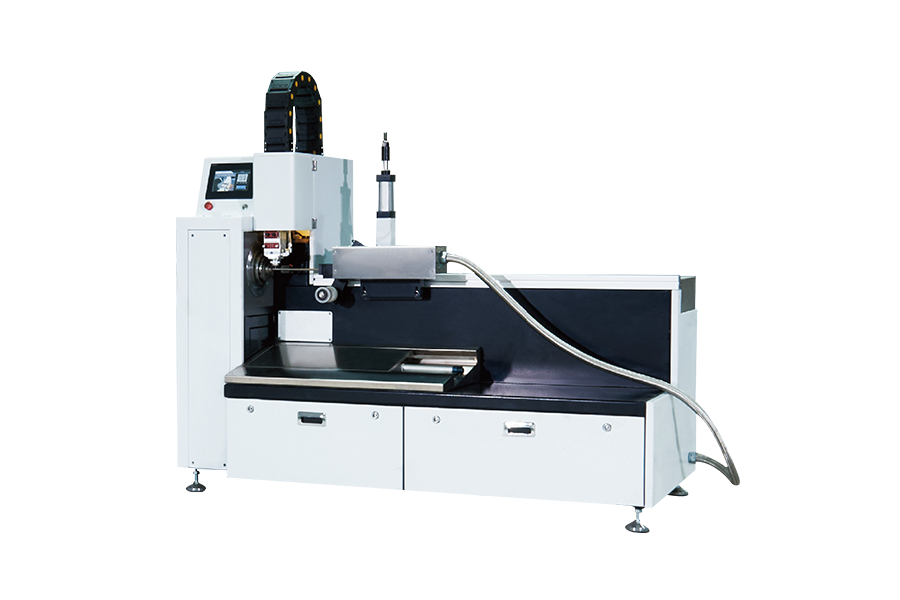

The imported all-electric servo closed-loop control system is adopted. The handheld laser welding system supports up to 25 axes of concurrent linkage. In the true sense, the multi-axis is concurrently linked, the bending action is smooth, and the mechanical operation is highly coordinated. It can connect different brands of manipulators and truss loading and unloading equipment according to its own needs.

The programming software is easy to learn, intelligent operation, practical. The edited workpiece shape is displayed at any time, and the self-inspection system can predict whether the edited program is correct in advance, avoiding the waste of workpieces and effectively protecting the equipment. In terms of function, it supports complex movements such as upper pressing dead edge, lower pressing dead edge, and arc that cannot be formed at one time by traditional bending machines.

The control system has a cloud operation and maintenance management interface, which can use the mobile applet to monitor the operation status of the equipment anytime and anywhere, understand the actual operation status of the equipment, and count the number of production workpieces in various periods.

FAQ of Panel Bender

Yes sure, pls firstly share with us the below points so we can offer our quotation for reference.

1) Your material type and coil width.

2) Your material thicknesses

3) The drawings you would need to do

4) Your coil weights

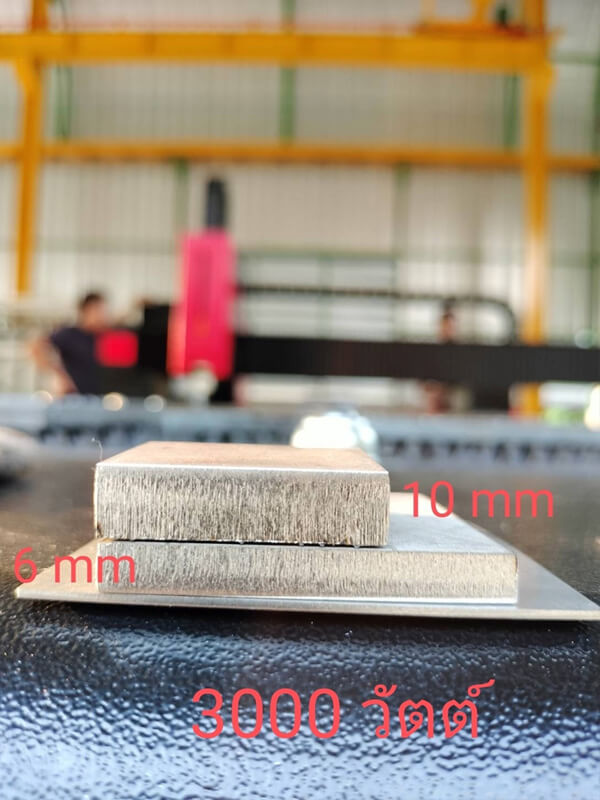

Yes sure, we works as the professional laser machine distributor welcoming the global partners for vising us and also welcome to make an appoint with our manager for checking the machine in locally

As a laser machine supplier, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Laser Cutter For Stainless Steel | Thanks to high precision, high speed, and lower costs on gas or labors or maintenance compared with traditional flame or plasma cutting method. Mor... | |

| Coil Sheet Production System | Remcor Technology offers a range of sheet metal coil line machinesolutions for coil sheet processing. Including the coil feeding system, levelling ... | |

| Laser Machine Manufacturer | Remcor had offered tailored solutions since 18 years ago, and we have helped our customers with their needs in the manufacturing industry. No matte... | |

| Sheet Metal Cutting Machine | Machine Used to Cut Sheet Metal Remcor fiber laser cutting machine can help to cut intricate shapes, designs, and small holes for the high quality... | |

| Laser Machine in Construction | Laser cutting and weldingtechnology is applied in construction industires for a wide range of metal materials such as mild steel, stainless steel, ... |

Same products

| Manual Single Axis Cnc Laser Pipe Cutting Machine | Seller: Zhejiang Huaqi Information Technology Co., LTD | JH-NC40-Al1 Manual Single Axis Cnc Laser Pipe Cutting Machine Equipment Attributes: - Through Hol... | |

| TBK 958S 20W Laser Machine Handheld DIY Marking Engraving Tool | Seller: Shenzhen Wikshu Technology Co. | Description TBK 958S Handheld Portable Laser Machine 20W DIY Laser Printing Engraving Mach... | |

| The 25th China(Guangzhou) Int'l Laser Equipment and Sheet Metal Industry Exhibition | Seller: GUANGZHOU JULANG EXHIBITION DESIGN CO., LTD | 2025China (Guangzhou) Int’l Metal & Metallurgy Exhibition The 25thChina(Guangzhou) Int... | |

| Tube Laser Cutting Machine | Seller: WUHAN REMCOR TECHNOLOGY CO.,LTD | Tube Laser Cutting Machine Remcor steel pipe laser cutting machine solutions can certainly meet a... | |

| Sheet Metal Cutting Machine | Seller: WUHAN REMCOR TECHNOLOGY CO.,LTD | Machine Used to Cut Sheet Metal Remcor fiber laser cutting machine can help to cut intricate sha... |