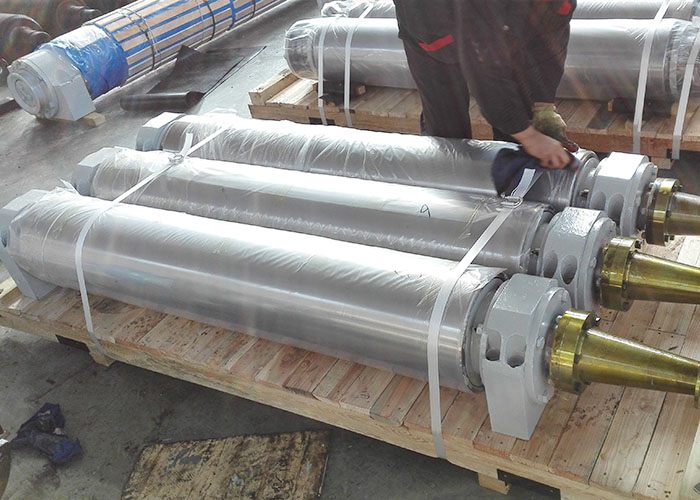

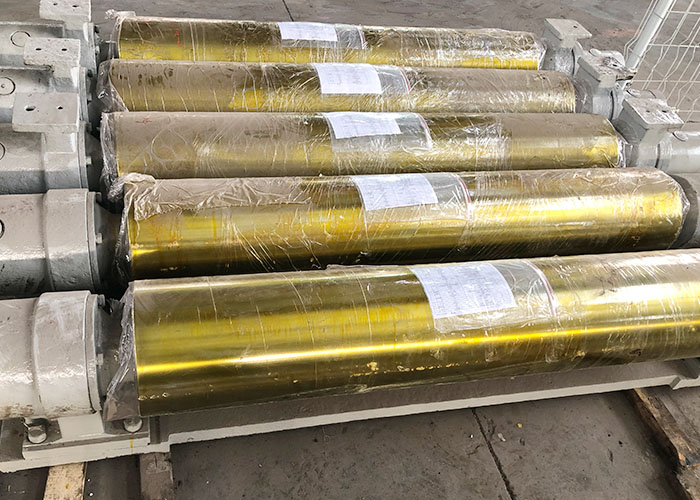

Forged roller for Steckel Mills High hardness Wear resistant

Forged roller for Steckel Mills High hardness Wear resistant-Surfacing welding,Built up welding,Cladding welding,Surfacing is a welding process used to apply a hard, wear-resistant layer of metal to surfaces or edges of worn-out parts. It is one of the most economical methods of conserving and extending the life of machines, tools, forged roll, and construction equipment. Dalian Longsheng Metallurgical Equipment Manufacturing Co., Ltd was founded in 2014,total registered capital is 20 million RMB,we are a professional manufacturer of Special welding and hot roller,covers an area of 20000m²,has more than 100 skilled employees,2 CWI international welding engineers, 1 TWI international welding inspection engineer, and 60 technician and QC inspector. Our management, technology, and production backbone are all from the original Dalian Huarui Heavy Industry Group . We are move first to obtain the quality system certification and have been providing professional services for industries like metallurgy, mechanical equipment, shipbuilding, ocean drilling, high rise buildings, and metal structures. The company has reached a leading level in China in terms of build-up welding, spraying welding, and thermal spraying technology .The company has many advanced production equipment including build-up welding machine,spraying welding machine, plasma spraying, CNC Lathe, machining center,grinding machine,milling machine, CMT robot automatic welding machine,micro-plasma arc welding and BP400 arc spraying. We also have various advanced testing equipment; CMM, laser tracker, Electronic Total Station, laser interferometer, large field metallic microscope, infrared carbon sulfur analyzer, Nitrogen, hydrogen, and oxygen combination analyzer, direct reading spectrometer, X-ray flaw detector γ Radiographic detector, magnetic particle detector, etc. These professional equipment provide strong guarantees for manufacturing high-quality products.

Other supplier products

|

|

China Forged roller Repair Wear resistant High hardness |

China Forged roller Repair Wear resistant High hardness-Surfacing welding,Built up welding,Cladding welding,Surfacing is a welding process used to ... |

|

|

Surfacing welding-Built up welding-Cladding welding China |

Surfacing welding-Built up welding-Cladding welding China-Surfacing welding,Built up welding,Cladding welding,Surfacing is a welding process used t... |

|

|

continuous caster roller-Cladding welding wear parts |

continuous caster roller-Cladding welding wear parts-Surfacing welding,Built up welding,Cladding welding,Surfacing is a welding process used to app... |

|

|

Surfacing welding-Cladding welding-Special welding-Surfacing welding roller |

Surfacing welding-Cladding welding-Special welding-Surfacing weldingroller

-Surfacing welding,Built up welding,Cladding welding,Surfacing is a weld... |

|

|

Surfacing welding Cold Rolling Mills roller HRC 62-73 |

Surfacing welding Cold Rolling Mills roller HRC 62-73-Surfacing welding,Built up welding,Cladding welding,Surfacing is a welding process used to ap... |

All supplier products

Same products