Cover Flux

Cover Flux(SATA-PF-340)

General Description of Cover Flux (SATA-PF-340)

The aluminium melt is extremely easy oxidation and inhale when it is in melting. A flux is required to have low melting, low density, good humidity, and can form a dense uniform protective film, which we called it cover flux.

SATA-cover fluxalso name cover flux aluminiumis used for covering of molten aluminium, it can form a cover layer on the surface of molten for prevent the molten aluminium react to oxidation.

Application of Cover Flux (SATA-PF-340)

Use Instruction: flux for aluminum meltingcan added at one time before refining or it can added in two batches,first add half cover flux to the molten aluminium and stir the melt and make the flux fully react to molten, then skimming the dross and spread the balance on the surface of the aluminium molten.

Advantage of Cover Flux (SATA-PF-340)

It can prevent the aluminium molten react with oxygen in the air.

It is a eco-friendly flux, less fume during working

It can separate the dross from aluminium molten, reduce metal loss

Low working temperature, suitable for kinds of furnace

Specification of Cover Flux (SATA-PF-340)

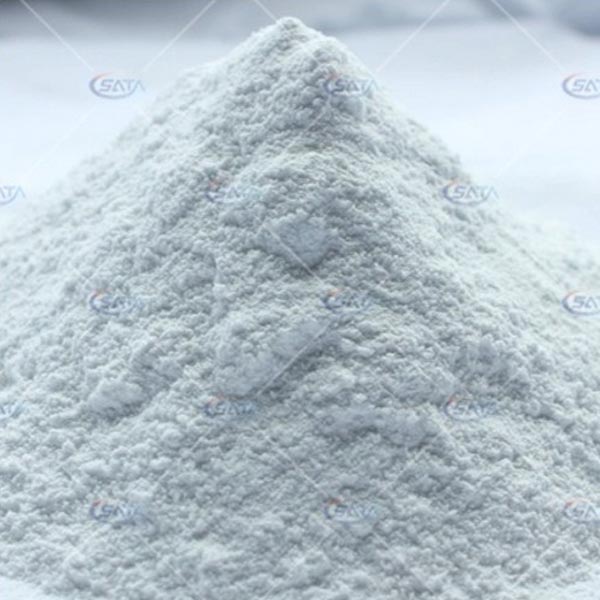

White mixed powder.

Aluminium melting temperature: 650-750℃.

Recommended Dosage: 1.5-3kgs/ton aluminium molten, 0.8-1.0kg/m2 of melt area. it should adjust according to the purity and air humidity.

Package:

Packed in 5kg (PE), 25kg (PP), 1000kg bags or customized

Stored in dry, well-ventilated place, and avoid direct sunlight,keep sealed before using.

Package of Cover Flux (SATA-PF-340)

Packed in 5kg (PE), 25kg (PP), 1000kg bags or customized.

Stored in dry, well-ventilated place, and avoid direct sunlight,keep sealed before using.

NOTE: This flux has serious hygroscopicity, please use immediately after opening.

Send product request

Other supplier products

| Drossing Flux | Drossing Flux(SATA-PF-310) Description of Drossing Flux (SATA-PF-310) SATA drossing flux is specially developed for removing the slag from the alum... | |

| Magnesium Chloride Hexahydrate Powder | Magnesium Chloride Hexahydrate Powder General Description of Magnesium Chloride Hexahydrate Powder Chemically, magnesium chloride is represented as... | |

| Recovery Flux | Recovery Flux (SATA-PF-320) General Description of Recovery Flux (SATA-PF-320) SATA Powder Fluxes for Recoveryis a kind of flux used flux for recov... | |

| Degassing Flux | Degassing Flux (SATA-PF-350) General Description of Degassing Flux (SATA-PF-350) Practice has proved that the hydrogen is the main cause of the po... | |

| Alal Alloy Flux | Aluminum is one of the lightest metals in the world. It’s also very strong, extremely flexible and corrosion resistant. Light, durable and fu... |

Same products

| MECHANIC M35 Flux Paste for Phone Motherboard Repair | Seller: Phonefix | The Mechanic M35 10CC Nano Flux Paste offers 98% new high activity. This high-efficiency, synergi... | |

| Lanrui AS50 Universal Repair Cream Oxidation Point Remove | Seller: ShenZhen VIP FIXPHONE Technology Co., Ltd, | Description LANRUI AS50 Universal Repair Cream for Mobile Phone/iPhone motherboard oxida... | |

| Mechanic M35 Nano Soldering Flux Paste for Chip IC Repair | Seller: ShenZhen VIP FIXPHONE Technology Co., Ltd, | Description Mechanic M35 10CC Nano Flux Paste for mobile phone motherboard BGA chip sold... | |

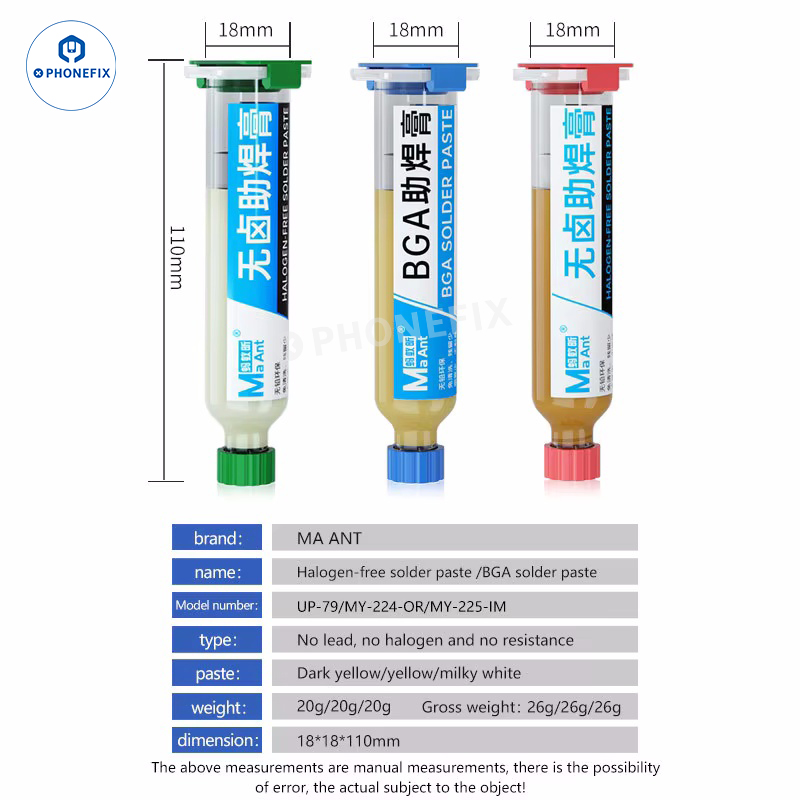

| MaAnt BGA Solder Paste Halogen-free Lead-free Repair Flux | Seller: Phonefix | MaAnt UP-79 MY-224 MY-225 halogen-free solder paste for mobile phone/electronic circuit board CPU... | |

| JTX Nano Conductive Silver Paste For Phone Screen Line Circuit Repair | Seller: Phonefix | JTX Nano Conductive Silver Paste repairs iPhone screen/green screen/white screen lines issues cau... |