SJSZ Conical Twin Screw Extruder

Twin screw extruder definition

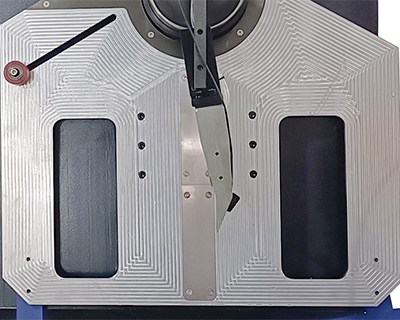

SJSZ Conical double screw extruder for saleis an advanced extrusion technology machine used for producing PVC pipes, profiles, sheets, and other plastic products. It consists of two screws that rotate within a conical barrel to melt and extrude the plastic material into desired shapes and sizes. It offers high efficiency, stable performance, and precise temperature and pressure control. This machine is widely used in the construction, automotive, and packaging industries.

SJSZ series conical double screw machinehas advantages such as forced extruding, high quality, wide adaptability, long working life, low shearing speed, hard decomposition, good compounding &plasticization, and direct shaping of powder material and etc. This extruder is equipped with AC motor, auto temperature controller, vacuum exhausting device etc.

Features of SJSZ Conical twin screw extruder china

Frequency conversion timing.

Hard-toothed Gearbox.

Material of the screw and barrel is 38CrMoAlA, nitrogen treatment, screw is designed especially for rigid PVC profile.

Screw adopts frequency conversion timing, Inverter is brand of ABB.

Cast-aluminum heating coil, barrel is fan cooling.

Vacuum degassing designed.

Fixed quantity feeding device, frequency conversion timing, ABB inverter.

Stainless hopper, side glass, with cover.

Concourse chip(inside is chrome plating ) is equipped on the extruder head, pressure sensor device is also equipped with.

Electric control cabinet: Contactor is brand of Siemens, temperature controller is brand of RKC(8 pcs), inverter is brand of ABB, current meter and voltage meter are digital display type, electrical outlet.

Technical Specification of SJSZ Conical Twin Screw Extruder

|

Model |

SJSZ-45 |

SJSZ-51 |

SJSZ-65 |

SJSZ-80 |

SJSZ-92 |

|

Screw diameter(mm) |

45/90 |

51/105 |

65/132 |

80/156 |

92/188 |

|

Rotation speed(rpm) |

45 |

45 |

45 |

||

|

Main motor(kw) |

15 |

37 |

55 |

110 |

|

|

Main motor(kw) |

80 |

120 |

250 |

400 |

750 |

|

Center height(mm) |

1000 |

1000 |

1000 |

1100 |

1200 |

|

Net weight(kg) |

2500 |

3000 |

4000 |

5500 |

8000 |

|

Dimensions(m) |

6*1.6*2.5 |

The Role of SJSZ Conical Twin Screw Extruder in the Manufacturing of PVC Pipes

SJSZ Conical Twin Screw Extruder plays a crucial role in the manufacturing of PVC pipes. The extruder uses heat and pressure to melt and mix PVC resin and other additives, such as stabilizers, plasticizers, and lubricants. The molten PVC is then forced through a die to give it the desired shape and size. The extruder's precise temperature and pressure control ensure that the PVC mixture is uniform and consistent, resulting in high-quality end products. Its high productivity and efficiency help to meet the increasing demand for PVC pipes in the construction industry while maintaining strict quality standards. Overall, the SJSZ Conical Twin Screw Extruder is an essential machine for PVC pipe manufacturing.

Integration of SJSZ Conical Twin Screw Extruder with In-line Processing Equipment

The integration of SJSZ Conical Twin Screw Extruder with in-line processing equipment, such as vacuum sizing tank, traction unit, and cutting machine, can significantly increase the extrusion process's efficiency. The in-line processing equipment works in sync with the extruder to produce high-quality end products at a faster rate. The extruder's precise temperature and pressure control help to maintain consistency and uniformity throughout the process. Moreover, the integration of in-line processing equipment reduces the need for manual labor, thereby increasing productivity and reducing production costs. This integration is an excellent option for large-scale PVC pipe manufacturing.

If you are looking for a reliable double screw extruder manufacturer,don't hesitate to contact us!

For more informationabout double screw extruder price, please feel free to contact us!

There are many plastic processing machine manufacturers, but we are one of the best choices for you.

Send product request

Other supplier products

| Plastic Crusher | plastic crusher/crushing machine/crusher machinery adopts imported high-quality tool steel, special cutting-tool. The installation of the cutting... | |

| DJQ Series HDPE Pipe Band Saw Cutter | DJQ Series HDPE Pipe Band Saw Cutter The DJQ Series HDPE Pipe Band Saw Cutter is a highly advanced piece of equipment that is specifically designe... | |

| Single Shaft Shredder | The Single Shaft Shredderis a heavy-duty piece of equipment used to shred huge waste bits into smaller, more manageable parts. It is extensively us... | |

| Armored/Common Floating Hose | Armored/Common Floating Hose Armored/common floating hoses are used in offshore oil and gas operations to move fluids like crude oil and natural g... | |

| PVC Pipe Bending Machine | pvc pipe bender for saleis a process equipment for acrylic, plexiglass, PC, PVC, SBS and other plastic sheets. Through accurate positioning of the... |