INDUSTRIAL BUFFING AND POLISHING MACHINES FOR SALE

INDUSTRIAL BUFFING AND POLISHING MACHINESFOR SALE

The polishing machine meaning is a device used to improve the appearance of a surface by removing imperfections and creating a smooth and glossy finish. Industrial buffing and polishing machines typically consist of a motorized rotating disc or pad that applies pressure to the surface being polished. The polishing machines for sale are commonly used in industries such as automotive, woodworking, and metalworking to polish a variety of materials, including metals, wood, and plastics. It is an essential tool for achieving a professional and flawless finish on various surfaces. If you want to know more about polishing machines meaning and buffing and polishing machines, please do not hesitate to contact Xihe Laser Welding Machine Chinamanufacturer.

TYPES OF INDUSTRIAL POLISHING MACHINES FOR SALEFROM XIHE

01

Drum Polish Machine

Automatic polishing, using Inovance PLC (programmable logic controller) control system.

02

Double Ended Polishing Machine

The equipment uses two methods of duplex position vertical and horizontal for cylindrical polishing to meet the product brightness and smoothness;

03

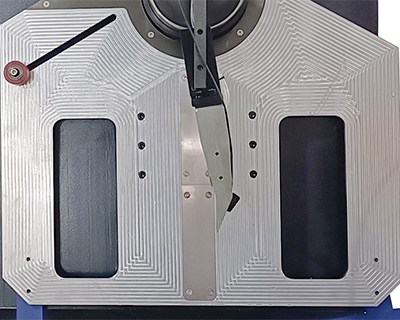

Sander Polisher Machine

The polishing wheel is made of hemp wheel material, and the upper, lower, front and rear are controlled by servo drive.

04

Stainless Steel Polishing Machine

The equipment is operated by touch screen, and the aerial manipulator is used to complete the clamping action, professional polishing T-type products;

Drum Polish Machine

Double Ended Polishing Machine

Sander Polisher Machine

Stainless Steel Polishing Machine

POLISHING MACHINE USES

Polishing machine, also known as grinding machine, is often used for mechanical grinding, polishing and waxing. Its working principle is: the motor drives the sponge or wool polishing disc installed on the polishing machine to rotate at a high speed. Due to the joint action of the polishing disc and polishing agent and friction with the surface to be polished, the purpose of removing paint pollution, oxide layer and shallow marks can be achieved. The rotating speed of the polishing disc is generally 1500-3000 r/min, mostly stepless, which can be adjusted at any time during construction. Polishing machine from Xihe polishing machine suppliers is mainly customized for the kitchen appliance industry to achieve a perfect appearance.

Hot Type Of Industrial Buffing And Polishing Machines For Sale:

drum polish machine

double ended polishing machine

sander and polisher machine

ss polishing machine

Polishing Machine Uses

POLISHING MACHINE INDUSTRIAL USING METHODS

1

Place the product to be polished on the material rack, the equipment is equipped with two rotatable material racks, the material racks can be switched at any time, and products can be added at any time, thus ensuring the continuity of production.

2

The product is put into the polishing fixture by the mechanical arm, and the fixture is rotated at a high speed, and the product is thrown vertically and horizontally at the same time. The two polishing procedures are carried out at the same time, which greatly shortens the polishing time.

3

The equipment adopts Inovance PLC (Programmable Logic Controller) control system, the polishing wheel is made of hemp wheel material, and the upper and lower fronts are controlled by servo drives.

What Is The Difference Between Buffing And Polishing Machines?

Buffing is a more aggressive process that involves the use of an abrasive compound to remove imperfections such as marks, scratches, and oxidation from a surface. The abrasive compound, typically in the form of a buffing wheel or pad, is applied to the surface with a buffing machine. The machine’s rotating motion combined with the abrasive compound effectively clears away the imperfections, leaving a smoother and more uniform surface.

On the other hand, polishing is a less intense process that focuses on creating a shiny and reflective surface. It utilizes a smoother abrasive material, such as a polishing compound or a polishing wheel, to refine the surface and enhance its luster. Polishing is often employed after buffing to further refine the surface and achieve a higher level of shine.

The choice between industrial buffing and polishing machines depends on the condition of the surface and the desired outcome. If the surface has visible scratches, marks, or oxidation, buffing is the recommended approach to eliminate these imperfections. Once the surface is smooth and free from blemishes, polishing can be employed to enhance its shine and create a mirror-like finish.

Xihe offers a range of industrial buffing and polishing machines that cater to various applications and surface materials. Our machines are designed with precision and efficiency in mind, ensuring optimal results for our clients. We understand that different surfaces require different levels of abrasion, and our machines are equipped with adjustable settings to accommodate these variations.

Advantages of Industrial Buffing and Polishing Machines

Efficiency and Time-saving: Xihe's industrial buffing and polishing machines streamline the finishing process, reducing production time and enhancing overall efficiency.

Consistency and Precision: These industrial buffing and polishing machines ensure a uniform finish, maintaining high quality and precise results across all workpieces.

Versatility: Xihe's industrial buffing and polishing machines are adaptable to a wide range of materials and finishes, offering versatility in application and accommodating various industrial requirements.

Quality Enhancement: The industrial buffing and polishing machines from Xihe contribute to an improved aesthetic and functional quality of finished products, meeting high industry standards.

Safety and Ergonomics: These industrial buffing and polishing machines are designed with safety features and ergonomic considerations, providing a secure and user-friendly environment for operators, and reducing workplace hazards.

Send product request

Other supplier products

| PAPER DRUM STAINLESS STEEL BELT CRIMPING MACHINE | PAPER DRUM STAINLESS STEEL BELT CRIMPING MACHINE This equipment is designed for crimping and forming after welding of paper drum stainless steel... | |

| AUTOMATION EQUIPMENT FOR AUTO PARTS INDUSTRY | For the auto parts industry, we have independently developed welding equipment such as brake shoe seam welding machine, fillet welding machine, plu... | |

| VERTICAL MILLING MACHINE | This vertical milling machine chinais made with commercial quality, giving you the best value. The versatile design allows you to work with a varie... | |

| LASER SEAM WELDING | Laser seam weldingis a superior welding technique that provides precise and efficient joining of two metal sheets without the need for a filler or ... | |

| PAPER DRUM STAINLESS STEEL BELT CRIMPING WELDER | This equipment is designed for crimping and forming after welding of paper drum stainless steel rings. It is connected with our automatic laser wel... |